An experienced electrical engineer will be very familiar with compact relays. There are plenty of brands in the market and they are essential in many applications. Today, we are going to share with you why Phoenix Contact PLC-Interface relay is the cream of the crop.

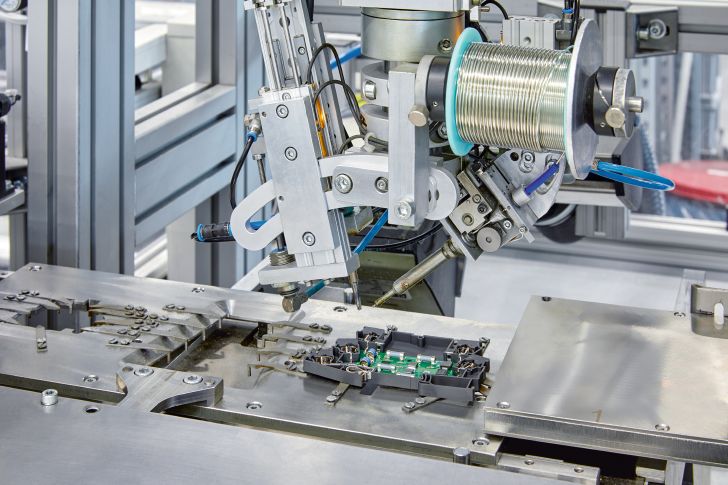

- High reliability by having no soldering points

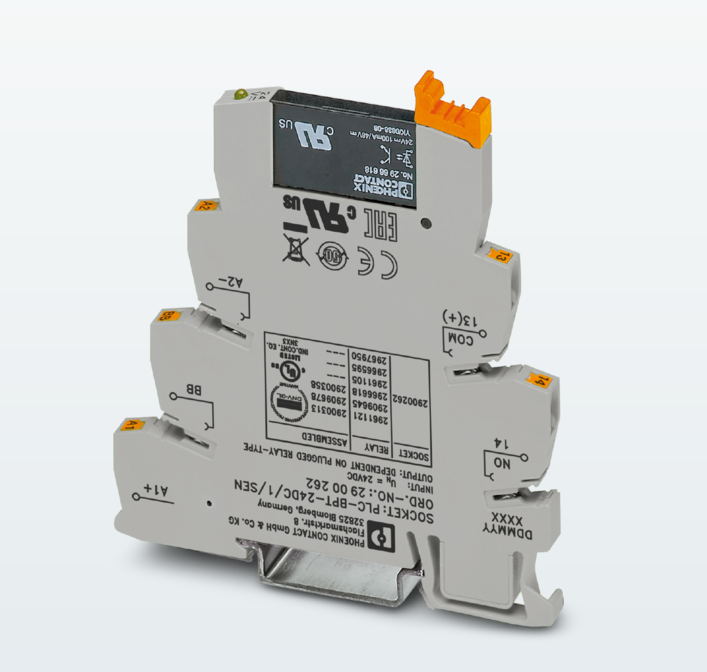

Unlike most compact relays in the market, Phoenix Contact PLC-Interface relay is made up of a single metal stamp circuit without any soldering points. Soldering joints are generally lower in strength and are advised to be used in high temperature applications. Corrosion might happen if the flux residue is not removed. Thus, by removing the weak solder points, we increase the reliability of our PLC-Interface relay.

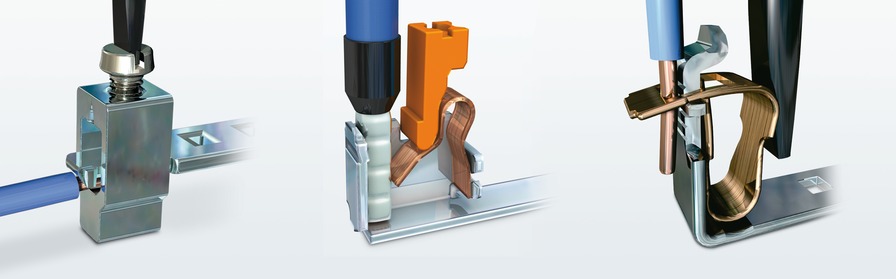

- Push-in Technology increases efficiency

We cannot imagine the time without Push-in Technology. It saves up to 80% wiring effort as compared to the good old screw connection. It was first implemented in Phoenix Contact terminal block and has slowly taken over as the preferred connection technology in most of Phoenix Contact products. Using a simple spring mechanism with a striking orange button, Push-in technology has won the hearts of many users. It is now available in PLC-Interface relay.

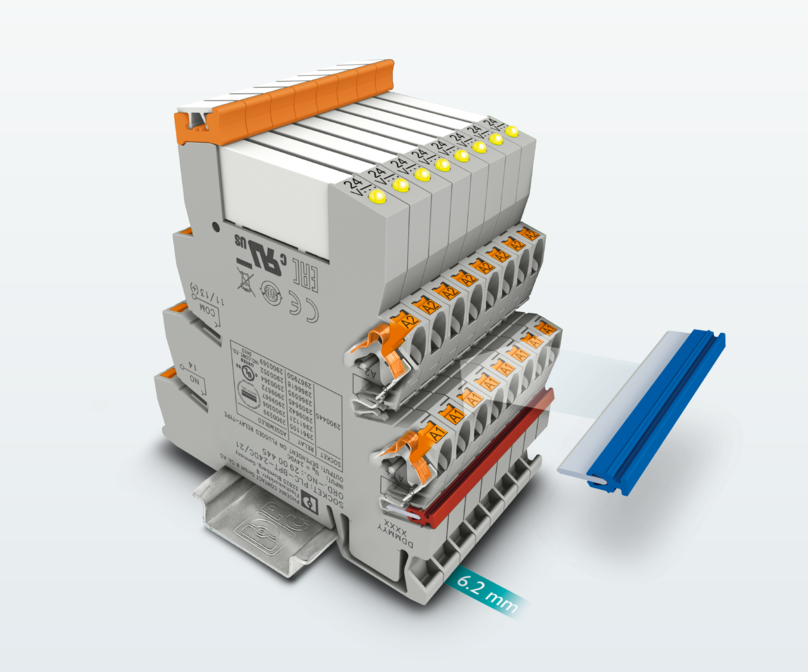

- Compactness and modularity saves space and reduces downtime

Real estate in the control cabinet is extremely precious. We are always trying to fit as many components as we can into the smallest possible control cabinet. With just 6,2mm thickness, you can fit over 160 pieces of PLC-Interface relay on a 1-meter DIN rail. By keeping the control cabinet small, you can save on the material cost. The modular system also ensures easy replacement of the relay in case of wear and tear. The pluggable relay reduces downtime needed for repair and maintenance.

- Wide variety of accessories provides ease of wiring

Phoenix Contact PLC-Interface relay comes with many accessories such as built-in bridges for convenient distribution. This makes installation and wiring faster as compared to doing it manually with wires. We also have a wide range of marking materials for easy and appropriate labeling of the relays.

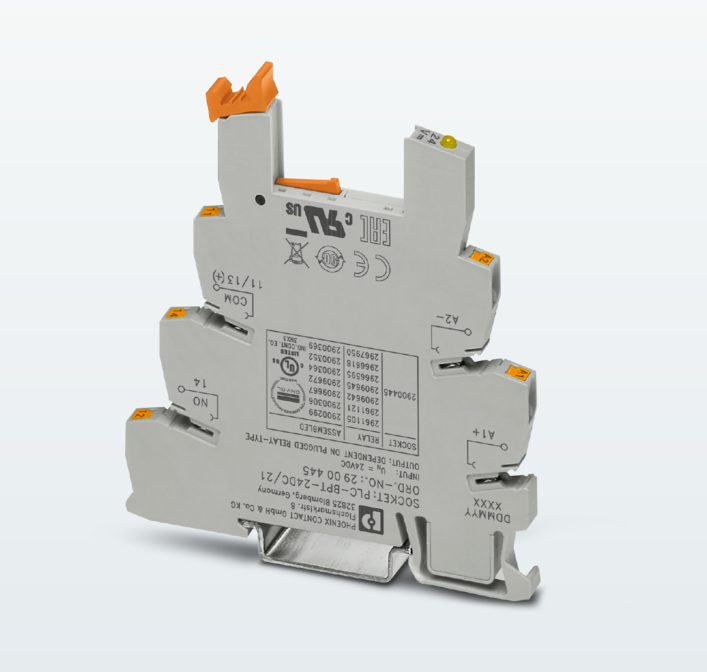

- High availability with solid-state relay and other features

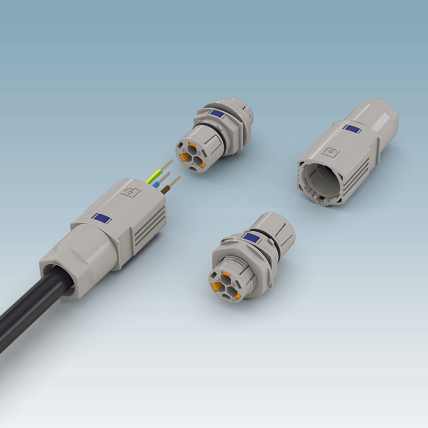

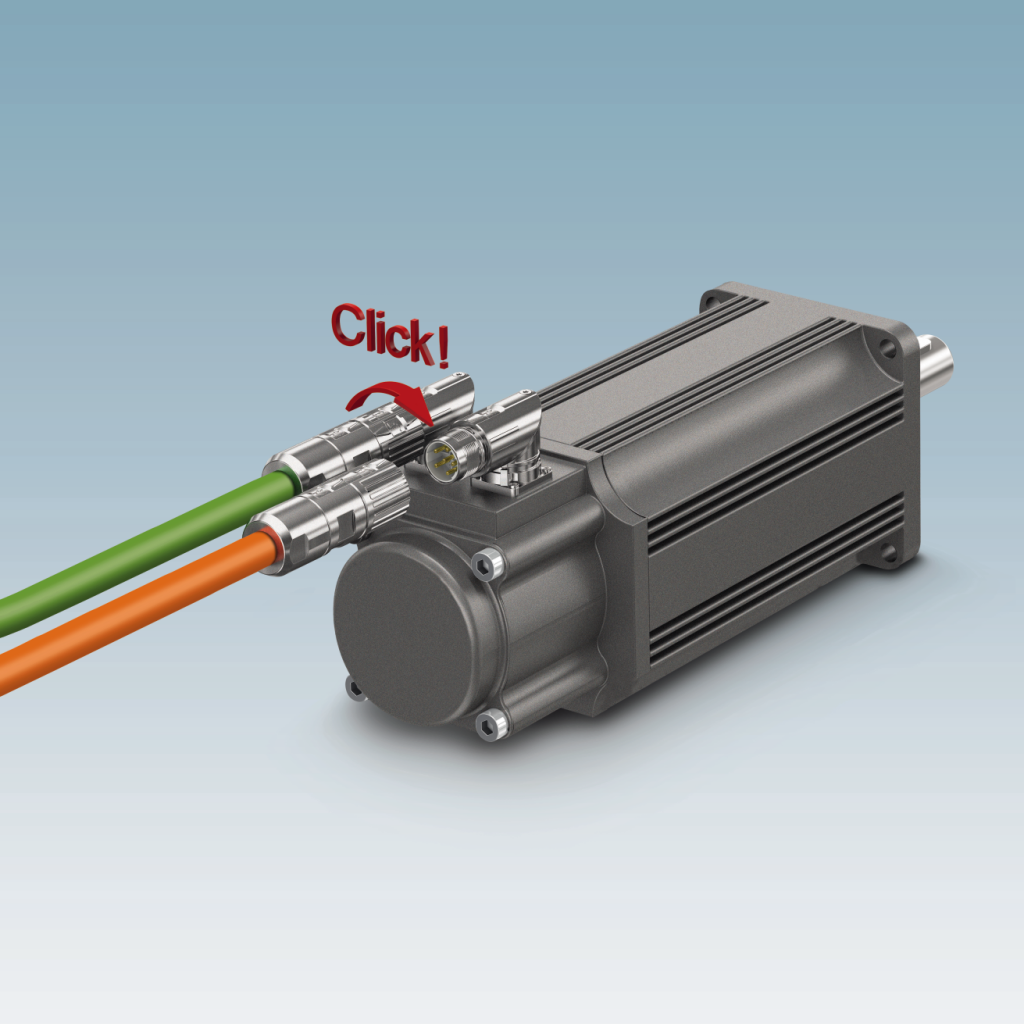

Solid-state relays are almost wear-free as they do not rely on mechanical movement to perform the switching. This gives the PLC-Interface relay a long service life. With integrated circuitry, PLC-Interface relays are protected against reverse polarity. Safety is further enhanced with the safe insulation between input and output (EN 50178). PLC-interface relay works well even in harsh and aggressive conditions. Rated IP 67, it is resistant against moisture and dust.

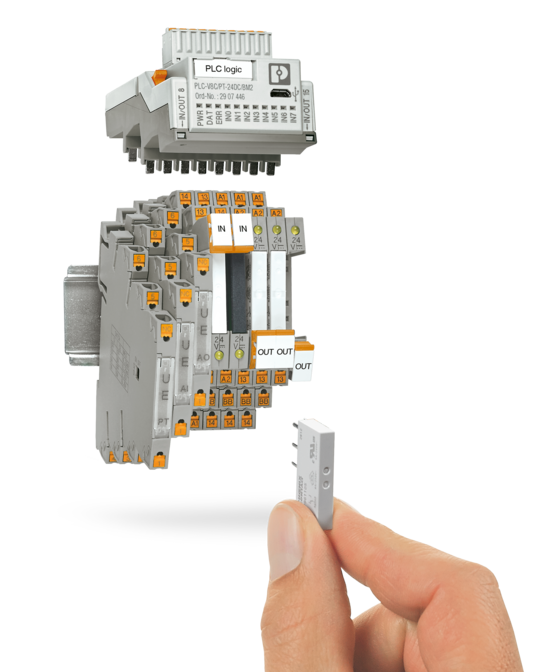

- We make smart relays smarter with PLC logic

Phoenix Contact is the pioneer to combine logic, interface and field connection. It gives the device the ability to switch and control the I/O signals, and combines the relays with analog modules. All can be achieved by simply plugging in a small controller into a standard PLC-Interface. With the width of 50mm, the small module provides up to 16 I/O signals. Extension modules can be added to increase up to 48 I/O signals. An intuitive software, Logic +, is also available for quick programming of the logic relay system.

Besides PLC-Interface relay, Phoenix Contact provides the best switching devices for all applications. To know more about the switch devices we have to offer, feel free to contact us at marketing@phoenixcontact.com.sg!

LC is the preferred connector for single mode fibre optic cables. Single mode is able to transmit a higher bandwidth over a longer distance. However, it’s more expensive as compared to multimode fibre optic cables.

LC is the preferred connector for single mode fibre optic cables. Single mode is able to transmit a higher bandwidth over a longer distance. However, it’s more expensive as compared to multimode fibre optic cables.