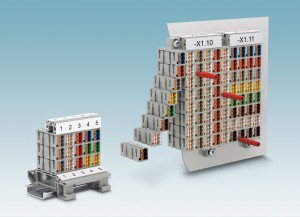

The new PSRmini safety modules from Phoenix Contact are the world’s slimmest safety relays with the power of a large safety relay. With their compact 6-mm width, they ensure high safety thanks to positively driven contacts. For users, these slim modules require up to 70 percent less space.

A comprehensive package of tests and approvals ensures that the modules can also be flexibly used in applications and environments that exceed the norm. For example, the relays are G3-compliant according to ISA S71.04-1985 for use in especially corrosive atmospheres and are IECEx-certified, thereby facilitating the decentralized design of an application down to Ex Zone 2. Repeat tests in a process plant, which are prescribed by standards, can easily be performed visually and directly on the device. Complex manual measurements that are currently required when using standard relays that are not forcibly guided according to EN 50205 are therefore often unnecessary. In addition, in some common control systems, monitoring of the controls of the coupling module may be influenced in the event of an error, so that the repeat test, the so-called proof test, can be designed to be almost fully automated. This increases efficiency since downtime can be reduced without necessitating additional effort for required hardware or installation.

The compact design of the safety modules is made possible through Phoenix Contact’s newly developed relay technology. The design is based on a slim, powerful, and force-guided basic relay characterized by minimal space requirements, low energy consumption, and high system availability. Despite its compact width of just 6 mm, the component features the same performance as traditional EN 50205-compliant elementary relays with forced guidance. The elementary relay from Phoenix Contact consists of an NO and an NC contact and is suitable for a modular application configuration. To achieve the manufacturing precision required to meet Phoenix Contact’s high quality requirements, the elementary relay and all of its individual parts are manufactured entirely at Phoenix Contact.

Since only the 6-mm modules require a single enabling contact, applications can be built with new and improved cost-effectiveness. The termination carrier also provides the option of using system cabling solutions for quick, error-free commissioning and connection in the field. The complete PSRmini range of safety relays consists of 28 products for mechanical engineering and the process industry.

![ProEXR File Description =Attributes= cameraAperture (float): 35.712399 cameraFNumber (float): 8.000000 cameraFarClip (float): 1000000015047466200000000000000.000000 cameraFarRange (float): 999999984306749440.000000 cameraFocalLength (float): 35.000000 cameraFov (float): 54.059361 cameraNearClip (float): 0.000000 cameraNearRange (float): 0.000000 cameraProjection (int): 0 cameraTargetDistance (float): 200.000000 cameraTransform (m44f): [{-0.0181089, -0.0704728, 0.997349, -2.16194}, {-0.406371, 0.911925, 0.0570582, 34.7475}, {-0.913529, -0.40426, -0.045152, -20.9426}, {0, 0, 0, 1}] channels (chlist) compression (compression): Zip dataWindow (box2i): [0, 0, 5059, 3599] displayWindow (box2i): [0, 0, 5059, 3599] lineOrder (lineOrder): Increasing Y name (string): "" pixelAspectRatio (float): 1.000000 screenWindowCenter (v2f): [0.000000, 0.000000] screenWindowWidth (float): 1.000000 type (string): "scanlineimage" =Channels= A (float) B (float) G (float) R (float) extraTex_VRayDirt1.B (float) extraTex_VRayDirt1.G (float) extraTex_VRayDirt1.R (float) materialID.B (float) materialID.G (float) materialID.R (float)](https://blog.phoenixcontact.com/wp-content/uploads/sites/14/2015/06/4741-300x217.jpg)