Many industries such as Building Automation (analysing of building operating parameters across various premises), Automotive (predictive warning for luxury vehicles), Land Transportation (think ERP 2.0 in Singapore!) has/will be implementing Industrial Internet of Things (IIOT) in its’ various forms for the different benefits and uses cases it provides.

If you are still confused about IIOT vs IOT vs Industrie 4.0 and other terms? Check out this link here.

The results have been intriguing and allowed those who have implemented such systems to stand out from their competitors amidst increasing competitiveness of their market.

In critical infrastructure (such as power industry), such a movement has been much slower. This is because a failure in critical infrastructure systems will have far reaching consequences unlike other industries. For example, an unnecessary power trip caused by a data packet not being received in time can affect hundreds or even thousands of residents in a large neighbourhood. Compare this to having a car breakdown in the middle of the road because the predictive warning for car servicing was not triggered!

IEC 61850 – What data can we track?

For Power Industry (Power generation, power grid operations, contestable energy market consumers etc.), we are in the infancy of a huge change, led by IEC61850 to achieve internet of things for power industry (commonly known as Virtual Heat & Power plant (VHP), Smart Grid or other variants).

IEC 61850 allows for

- Interoperability: with systems and products from different manufacturer designed and

communicating in the same way, Power grid operators, Power Generators, Power Consumers can their own systems to communicate with other systems easily.

- Industrial hardening of equipment: Components of systems needs to comply with IEC61850-3 which require hardening of industrial components, able to withstand the harsh condition of power industry, such as high Electromagnetic Interferences.

- Common system architecture and easy naming nomenclature of data points, allowing for integration into one BIG virtual network to be much simpler.

And these in terms allows for some pretty cool things in line with IIOT:

Predictive maintenance

Imagine knowing exactly when to replace the switchgear/transformer parts and knowing when it will fail! Switchgear/transformer spare parts usually require lead time. Knowing in advance before the electrical assets needs replacements allows power grid operators/ power generators to prepare for the spare parts in advance, minimizing risk for downtime.

Proactive maintenance

Instead of waiting for something to happen before we fix it, there is an increasing trend that engineers worldwide are always studying and trying to understand their system better!

Increased productivity

At present, checks on health of systems and electrical assets are periodically conducted. Unfortunately, there is no real good reason why a monthly period is chosen over a bi-annual check. This is a waste of precious resources as manpower is conducted to do meaningless checks. This time can definitely be better spent implementing a strong IIOT system that cuts down on these wastages and allows for a more advanced form of maintenance!

With these building blocks in place and obvious advantages, the last remaining challenge will be to adopt IIOT for Power Industry, i.e. where should we start to monitor and collect data from?

IIOT for Power Industry

For this, IEC is in the midst of a technical review for IEC 61850:

Part 90-3: Using IEC 61850 for Condition Monitoring Diagnosis and Analysis

This part of the standard will provide standardization for information modelling, exchange and configuration techniques for Condition Monitoring & Diagnosis for Power Utility Automation. What this mean is that in this part of the standard, there will be explicit description of how you can use IEC61850 to achieve predictive/proactive maintenance and increase productivity! There will be guides on which part of the switchgear/transformer/cables you should monitor and how exactly you should be monitoring them.

At Phoenix Contact, we have summarised IEC 61850 with regards to the portions it recommends condition monitoring and we are glad to share the summary below:

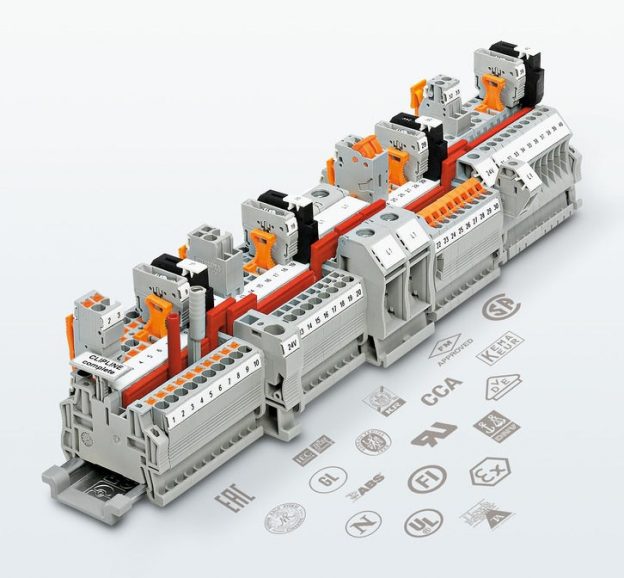

At Phoenix Contact, we also have a wide range of reliable IEC61850-3 industrial hardened components necessary for implementing of IEC61850 systems. Products include Network Switches, Ethernet to Fibre Media Converter, Parallel Redundancy Modules, Bus Couplers/IOs and Power Supply (AC to DC or DC to DC).

Do you want to know more about IEC61850/IIOT or how exactly condition monitoring can be done to stay ahead of IEC standards? Leave us your contact at marketing@phoenixcontact.com.sg and we will be in touch with you shortly.