Unexpected power interruptions not only cause your machine losses in productivity but may also cause unforeseen damages with serious consequences. Do not take any risks; we have the ‘smart’ solution safeguards your machine with zero downtime.

Typical problems in the power supply which cause unexpected interruptions:

- A blackout is the total loss of power in an area that results from power stations tripping. It may last from hours to days depending on the nature of the problem.

- A brown-out (or drop in voltage) may happen to an undersized electrical power system that struggles to cope with a rise in electricity demand or voltage drop due to the starting of heavy loads. In such a situation, it may last from seconds to minutes, just like the dimming experienced by lighting when the voltage sags.

- A fault on a power line, e.g. short-circuit. Power is automatically restored once the fault is cleared. This interruption typically last from milliseconds to seconds.

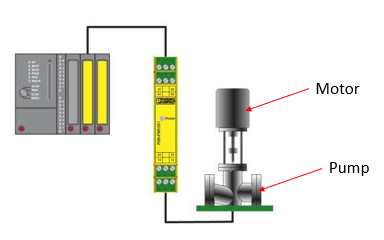

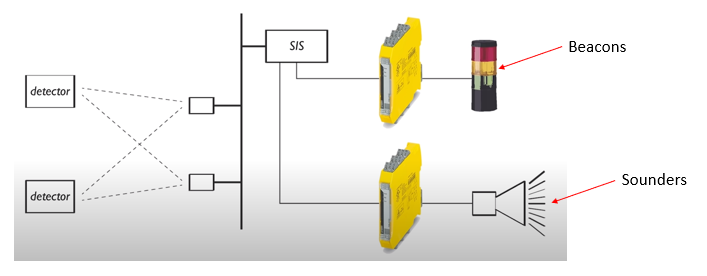

In such situations, the machine can be protected with an uninterruptible power supply (UPS) solution which targets to ‘bridge the gap’ by providing sufficient backup power over time, to activate standby generators, or initiate protected system shutdown which ensures the machine protection with operational continuity and availability.

To achieve the highest machine availability, it is critical for the reliable UPS solution to build in with intelligent control and monitoring. For example, the battery management system ensures fast and safe battery charging, extended load management, and communicative at the system level with important diagnostic, preventive, and predictive information. E.g. state of charge (SOC), state of health (SOH) of battery, required charging time, and data logging.

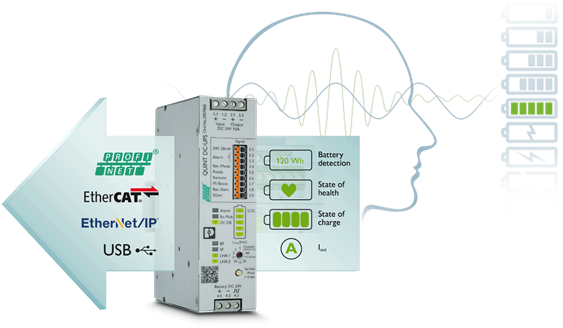

For your machine with zero downtime, I would like to introduce our QUINT UPS with IQ technology. Intelligent UPS monitoring and control realized not only through warnings and alarm signalling but made possible through connectivity and communication with high-level controllers via industrial network interfaces.

QUINT UPS – Intelligent UPS with Industry 4.0 ready, make your machine reliable & smarter

IQ Technology for an intelligent UPS system & battery management system (BMS)

- State of Health – reports on the remaining lifetime of the energy storage device, and warns of pending failures in good time

- State of Charge – describe the current state of charge and the remaining energy storage life

- Safe & efficient charging – adapts the charging current and thereby ensures the fastest possible charging and maximises service lifetime for different battery technologies, e.g. AGM-VRLA, LiFePO4 etc.

Communicative interfaces (smart & connected device)

- First intelligent QUINT UPS for integration into established industrial networks

- Easy integration – Profinet, EtherNet/IP, EtherCAT, Modbus, USB

- Available in all four performance classes 5A, 10A, 20A and 40A

- Intuitive configuration setup through UPS Config software

- Simple monitoring & control with warnings & alarm signals setup

- Extended load management

- Energy monitoring

- PC shutdown function

- Cold-start function

QUINT CAP – Battery-less UPS solution, completely maintenance free

- Long service life & maintenance free, thanks to double layer capacitor

- Reliably bridge short interruptions lasting up to 30 seconds

- Compact modular, easy retrofit & system upgrade

- Intelligent technology for preventive monitoring

- Wide operating temperature

Having an uninterruptible power supply (UPS) isn’t technically necessary to run your system, but by having one that can protect your application from damage will save you from heartbreak and avoidable expenses in the future. Contact us now for no obligations technical advice!