Phoenix Contact PLC Interface Relay is one of the most, if not the most widely used slim type relay in the market. This can be attributed to the fact that Phoenix Contact is the pioneer of this slim relay and it addresses the requirements of the industry. Besides that, there are numerous features that this range of relay has that differentiate Phoenix Contact from similar competitors.

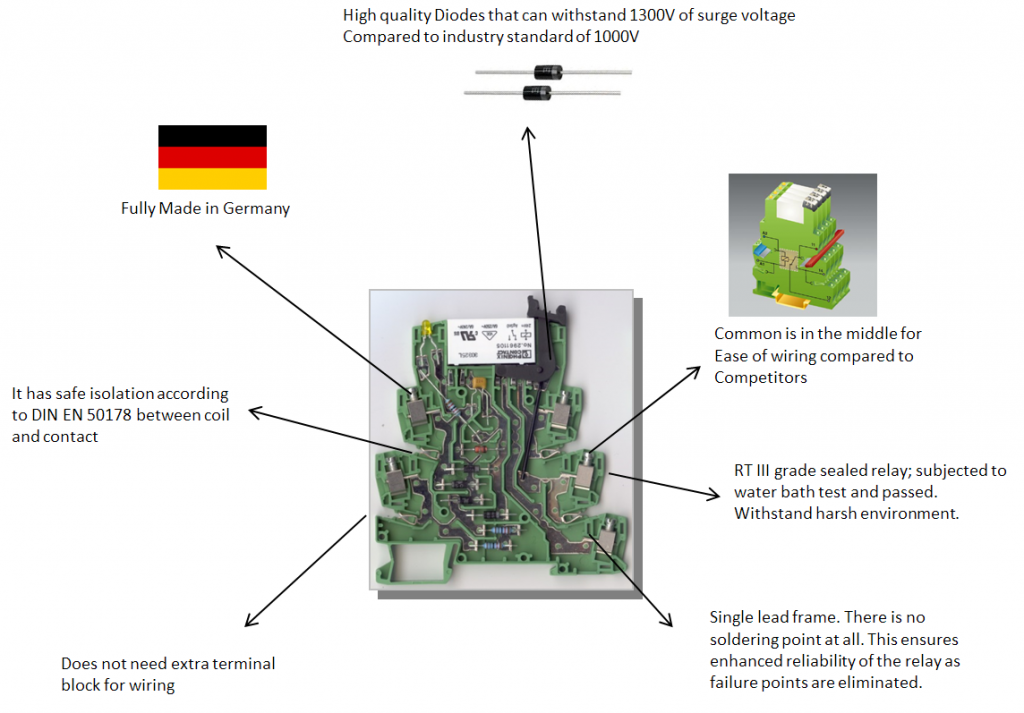

- The relay is fully made in Germany. On top of that, the production process is fully automated by machines in an environment with tight quality control. This ensures consistency, precision and high quality.

- The relay’s internal circuitry is made from a single lead frame. This means that there is no soldering and therefore, no single or odd weak point of potential failure. Consistency is also guaranteed as soldering is mostly done by humans and thus will be susceptible to quality control issues.

- Furthermore, the single lead frame technology has better heat dissipation and distribution technology over competitor’s product that uses PCB technology. This is because PCB technology tends to have concentrated heat spots that will weaken the relay over time. Phoenix Contact’s design allows for lower overall panel temperature for the end user.

- The relay is fully encapsulated and certified RT III grade and water and bath tested. This ensures that the relay will survive and operate even after exposure to water and high moisture and humidity. There are other brands in the market that does not have such degree of protection in the relay.

- The quality used for our components are also rated above the industry standards. Phoenix contact use diodes that are rated at 1300V compared to the 1000V that is typically used by others. This will ensure even higher threshold to withstand unexpected incoming surge.

- On top of these advantages, the Phoenix Contact PLC Interface relay is also versatile as it can be transformed into a PLC with integrated relay by adding a module called PLC Logic. This solution can be used for applications that require simple automation.

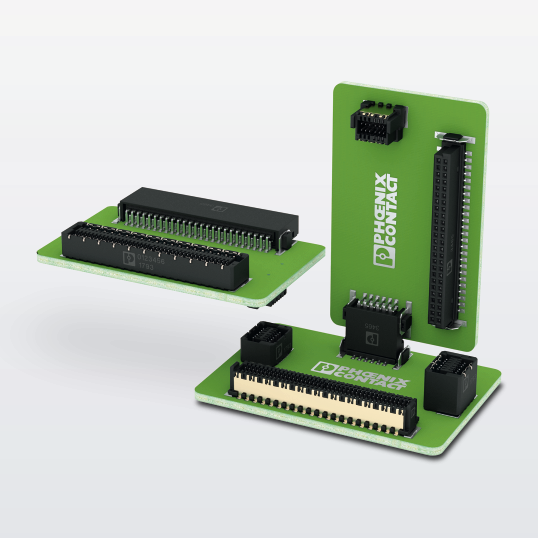

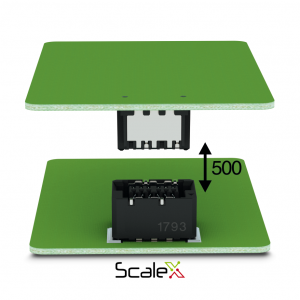

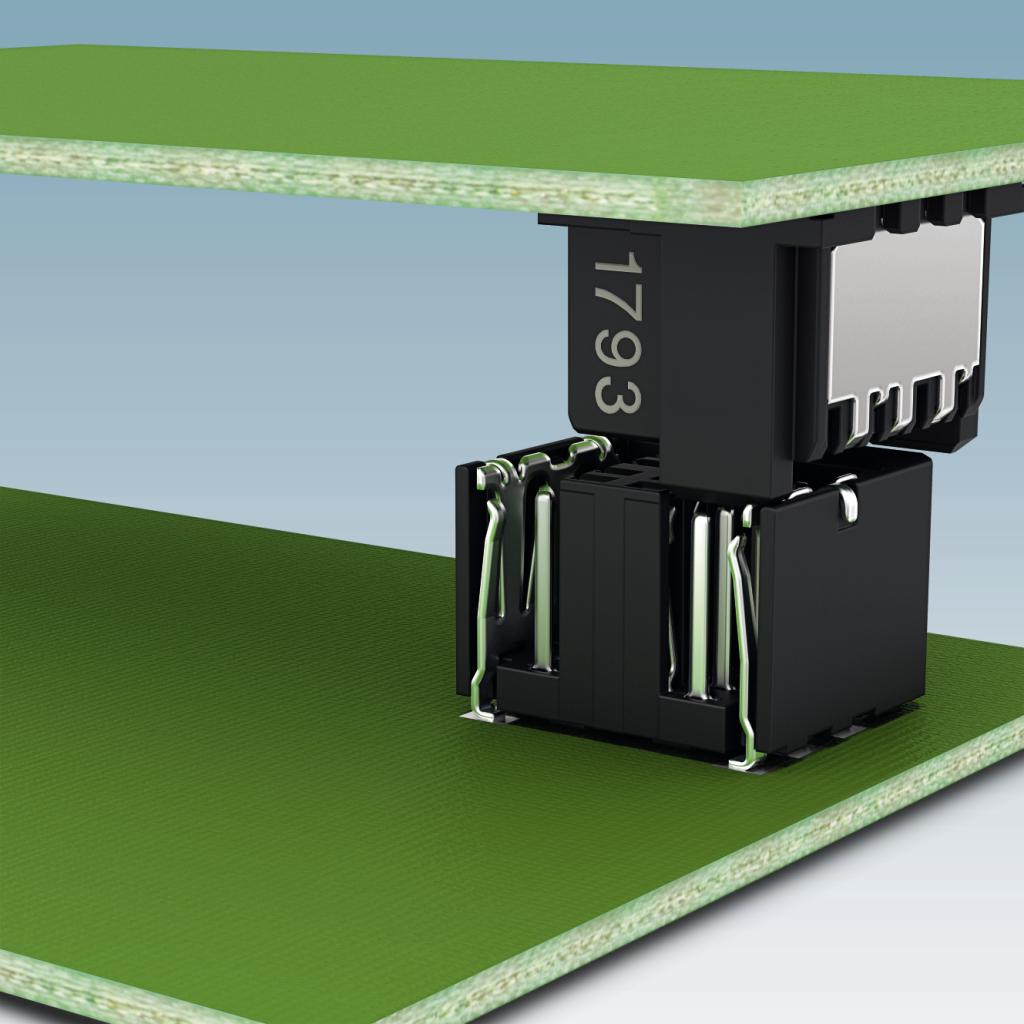

- The PLC Interface relay can also be used as a system cabling solution that will benefit users in terms of reducing manpower installation time and also reduces space required in the electrical panel. This can be achieved by plugging in a system cabling adapter on the PLC Interface Relay.

Interested to find out more? Get in touch with us at marketing@phoenixcontact.com.sg!