Phoenix Contact has been serving the railway industry for decades, especially for rolling stock and signalling. Safety and reliability has always been our number one concern when developing products for railway applications.

Phoenix Contact has been serving the railway industry for decades, especially for rolling stock and signalling. Safety and reliability has always been our number one concern when developing products for railway applications.

Safety on Board

The basic requirement for safety and reliability is standard compliance. Phoenix Contact has been certified by the International Railway Industry Standard (IRIS) since April 2008 and this standard is based on the quality management standard DIN EN ISO 9001, which has been extended with international railway-specific requirements. The ongoing tests during the development and production cycle of the products are essential to guarantee the product quality.

On top of that, all rail-specific products from Phoenix Contact fulfill the standards of DIN EN 50155, an international standard covering rolling stock; DIN EN 50121 electromagnetic compatibility; and EN 45545, fire protection on rail vehicle. Besides, shock and vibration test, material test and other fire protection is also critical for the railway application.

Safety should not be limited to the big ticket items and should even be extended to the passive component level. For example, the cable markings like shrink sleeve should be halogen-free and fulfill DIN 5510-2 with an oxygen index of 34.9%. besides being halogen-free, the cable ducts should enable individual bars to be broken without using any tools or resulting in any burr through defined breaking points according to EN 45545-2 (R22/R23:HL3). Behaviour in fire is another key concern and the plastic used for Phoenix Contact’s terminal blocks is halogen-free polyamide PA 6.6; which meets the highest safety requirement of UL 94 V0.

Push-in Terminal Blocks and Marking |

Cable Management |

Network on Board

Nowadays, commuters demand for “Internet on board” has made the information and infotainment systems essential in trains. The M12 network connectors with a mechanically robust design, in compliance with IEC 61076-2-101, together with high quality cables meeting the requirement of EN 45545-2 will ensure reliable communications. The heavy-duty connector, compliant with IEC 61373, with modular contact inserts form a flexible and safe transmission of signal and power circuit on rolling stock carriage connection and simultaneously ensures comprehensive protection in the event of electromagnetic interference fields.

Halogen-free Polyamide PA 6.6 |

M12 Network Connector |

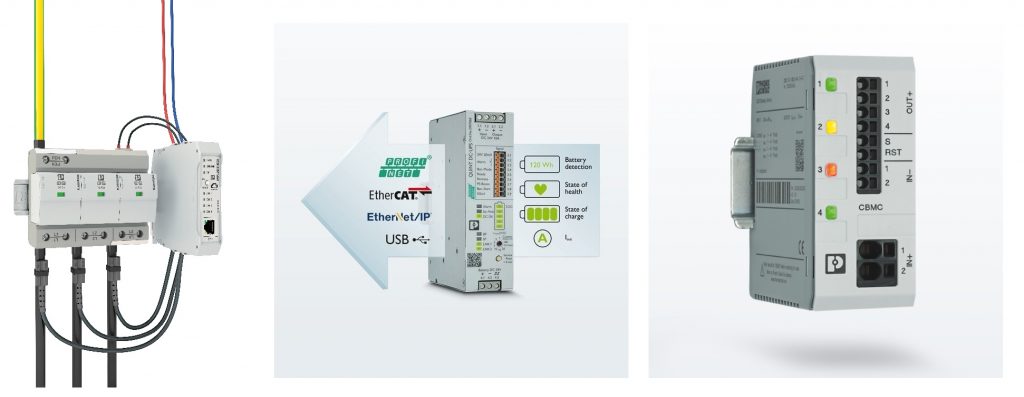

Surge Protection

Surge voltages and lightning strikes are common issues in signalling, hence the surge protective device (SPD) become significantly important to maintain reliable signal transmission. Phoenix Contact’s SPD has been tested according to IEC 61643-21 and the plug can be disconnected for test and maintenance by using the portable test laboratory. According to IEC 62305-3, the SPD must be tested regularly and the test values should be documented and traceable. Additional features like multi-stage monitoring (green – operating, red – fail and yellow – reach performance limit) for predictive maintenance and remote signalling for early detection of overloaded SPD can help to further enhance reliability.

HEAVYCON HPR |

HEAVYCON Modular Inserts |

Signal SPD with multi-stage monitoring (PT-IQ) |

Signal SPD with remote signalling (TTC) |

Power Supply

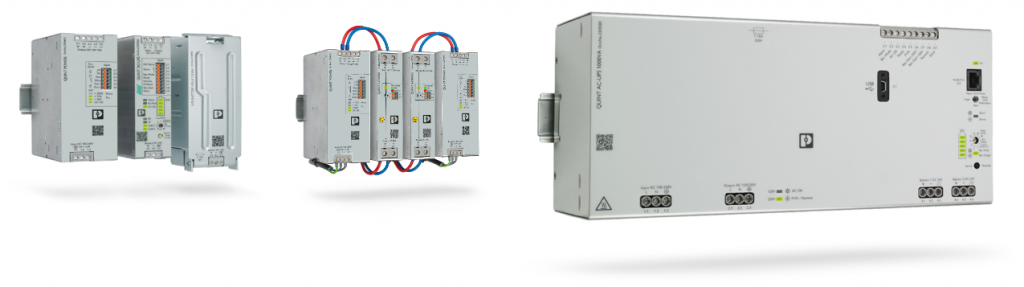

The power supply unit (PSU) is used to convert main AC to low-voltage regulated DC power and it should at least be compliant with EMC Directive 2014/30/EU, IEC 60950-1, DIN EN 61558-2-16 and UL 508. To ensure smooth operation and maximum uptime, the redundancy setup of the power supply cannot be overlooked.

A redundant system can made up of two power supplies and a diode or Phoenix Contact’s O-RING to prevent back flow of current. An ORING being a more advanced and modern redundancy module compared to the diode, comes with auto-current balancing (ACB) technology which ensures the power supplies work equally hard. This enables the power supplies to have a longer and more consistent lifespan.

The redundancy status as well as the status of the ORING can be monitored, whereas this cannot be done with a DIODE. The PSU becomes more reliable and dependable when it is capable of sending analogue signals to control system on measurement values such as real time current, voltage and power for early detection of operational fault as well as critical information to the user.

QUINT 4 Power Supply With Diode |

QUINT ORING with ACB |

Transporting You into the Future

Phoenix Contact will continue to develop the products or solutions that suit railway application and safety and reliability will always be the top concern on top of ease of installation, operation and maintenance.

To find out more about the solutions that Phoenix Contact has for the railway industry, check out our website or leave us your contact at marketing@phoenixcontact.com.sg and I will get in touch with you as soon as I can.

For many years, Phoenix Contact has been a reliable partner of the Railway Industry, supplying products such as Power Supply Unit, Terminal Blocks, Heavy Duty Connectors for railway applications. In the recent years, Phoenix Contact has invested a significant amount of effort to create innovative products such as controllers and ethernet switches for automation applications.

For many years, Phoenix Contact has been a reliable partner of the Railway Industry, supplying products such as Power Supply Unit, Terminal Blocks, Heavy Duty Connectors for railway applications. In the recent years, Phoenix Contact has invested a significant amount of effort to create innovative products such as controllers and ethernet switches for automation applications. The new FL 2000 Managed Switch was officially launched in April 2017 during the Hannover Fair. This new series of Ethernet Switch was specifically developed to bridge the gap between simple unmanaged switches and complex managed switches which are already available within Phoenix Contact product portfolio.

The new FL 2000 Managed Switch was officially launched in April 2017 during the Hannover Fair. This new series of Ethernet Switch was specifically developed to bridge the gap between simple unmanaged switches and complex managed switches which are already available within Phoenix Contact product portfolio. Phoenix Contact has been serving the railway industry for decades, especially for rolling stock and signalling. Safety and reliability has always been our number one concern when developing products for railway applications.

Phoenix Contact has been serving the railway industry for decades, especially for rolling stock and signalling. Safety and reliability has always been our number one concern when developing products for railway applications.

The main function of a solar module is to convert solar energy into electrical energy. A Solar module consists of a number of silicon cells which when illuminated by the sun, will produce photons that can generate electrical current. A set of Solar Panels in one system is called an Array. Generally the most widely used solar modules are crystalline type either Monocrystalline or Polycrystalline. While thin film solar modules are still rarely used (in Indonesia). A solar cell can produce a voltage of approximately 0.5 volts. So a 12 volt solar cell consist of about 36 cells.PLTS Off-grid will consist of several solar modules according to their capacity. For example, a 10 kWp PLTS will consist of 50 units of 200 Wp solar modules or 100 units of 100 Wp solar modules. These solar module is arranged in series and parallel with certain configuration.

The main function of a solar module is to convert solar energy into electrical energy. A Solar module consists of a number of silicon cells which when illuminated by the sun, will produce photons that can generate electrical current. A set of Solar Panels in one system is called an Array. Generally the most widely used solar modules are crystalline type either Monocrystalline or Polycrystalline. While thin film solar modules are still rarely used (in Indonesia). A solar cell can produce a voltage of approximately 0.5 volts. So a 12 volt solar cell consist of about 36 cells.PLTS Off-grid will consist of several solar modules according to their capacity. For example, a 10 kWp PLTS will consist of 50 units of 200 Wp solar modules or 100 units of 100 Wp solar modules. These solar module is arranged in series and parallel with certain configuration. In a solar power plant, solar panels can be arrayed in parallel to produce a larger current. Combiner boxes are used to connect the positive foot of solar panels to one another. Similarly, for negative legs. The positive foot end of the solar panel is connected to the positive charge controller leg and so is the negative leg. The resulting solar panel voltage will be used by the charge controller to charge the battery.

In a solar power plant, solar panels can be arrayed in parallel to produce a larger current. Combiner boxes are used to connect the positive foot of solar panels to one another. Similarly, for negative legs. The positive foot end of the solar panel is connected to the positive charge controller leg and so is the negative leg. The resulting solar panel voltage will be used by the charge controller to charge the battery.