Push-in Terminal blocks in vertical orientation?

Yes, I am sure most of us are aware of the easy-installation technology, called Push-in Technology. If you have never heard of it, please allow me to explain it with Phoenix Contact’s history.

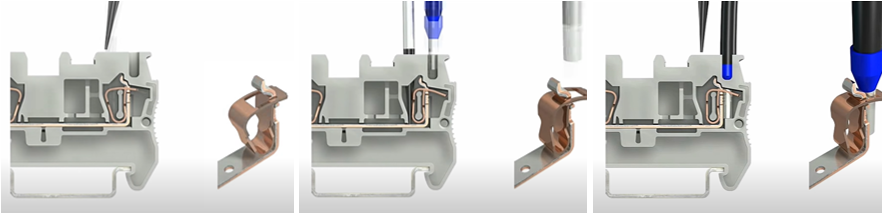

Phoenix Contact was the first to develop modular terminal blocks. It actually started with screw terminal blocks and then gradually innovated with newer technologies.

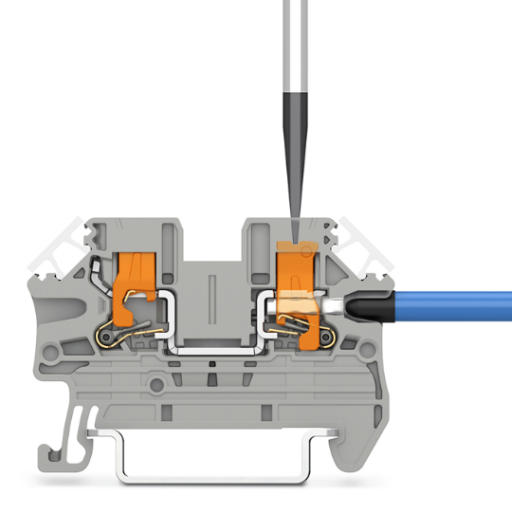

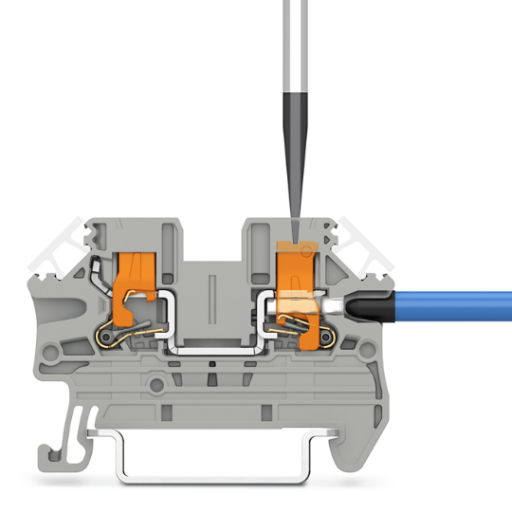

Moving on from screw terminal blocks, we came up with spring-cage terminal blocks. Using the screwdriver, the spring-cage would be opened, allowing the user to install the conductor.

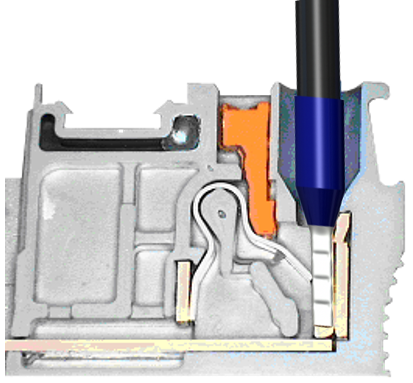

And finally, we have Push-in technology which does not require you to get any tools to install rigid or ferrule fitted conductors. Yes, all you have to do is just slot the conductor into the hole and push it in, Voilà!

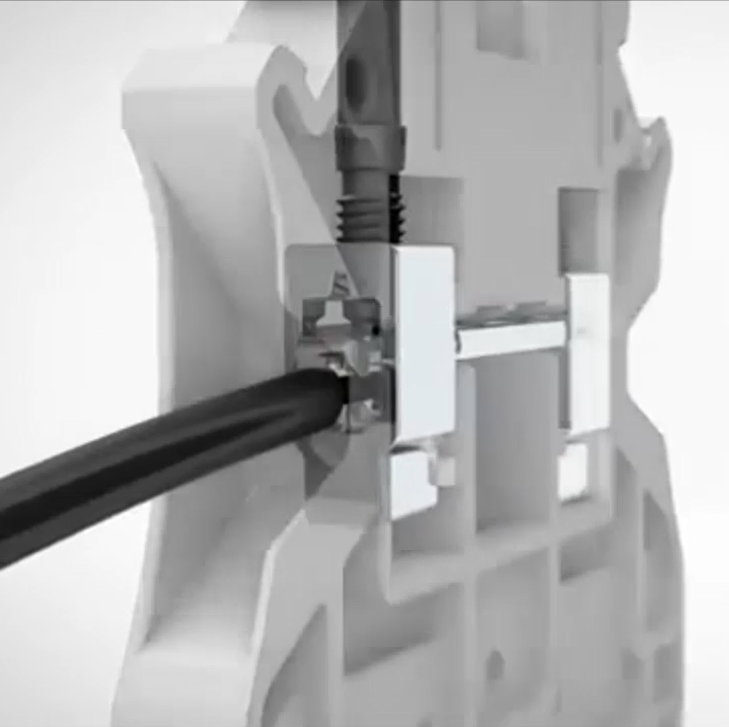

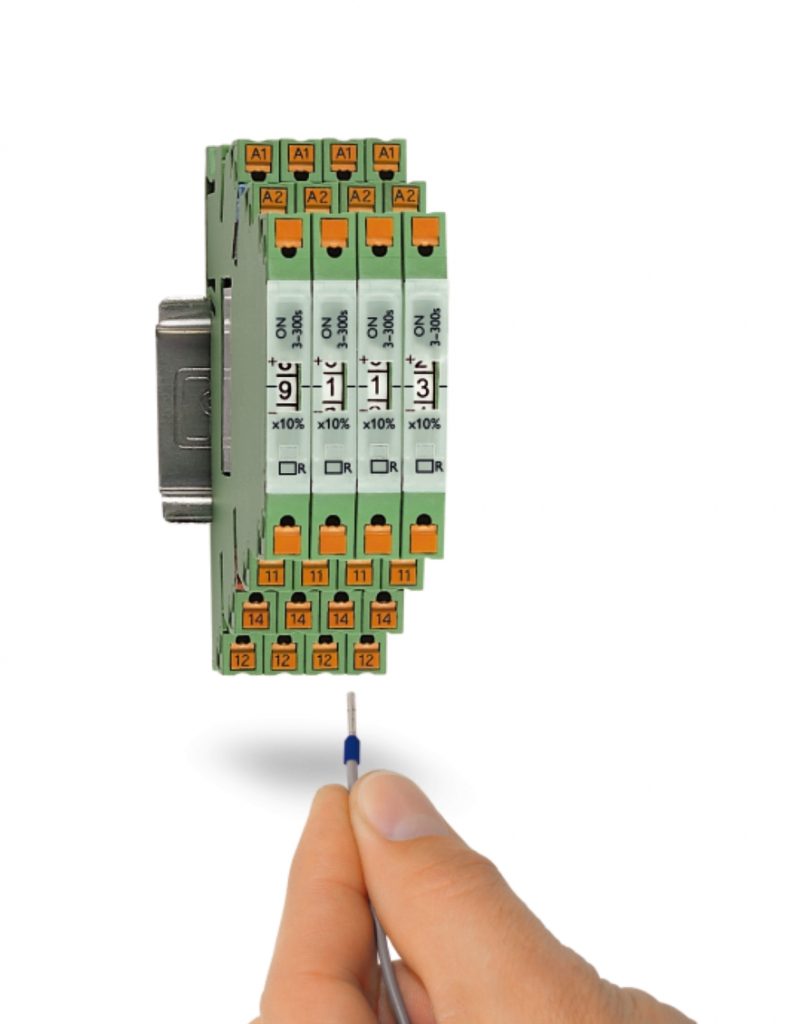

Again, with Phoenix Contact’s continuous innovation, we did not stop here. We now have lateral Push-in technology!

Instead of inserting the conductor from the top, now you can push it in from the side.

So, how does it benefit us more?

- Best Ergonomics

Just like PT terminal blocks, you can connect rigid or ferrule fitted conductors directly without using any tools. Regardless of the listed conductor size you use, the contact spring ensures maximum contact and conductor pull-out forces with a vibration-resistant, gas-tight connection.

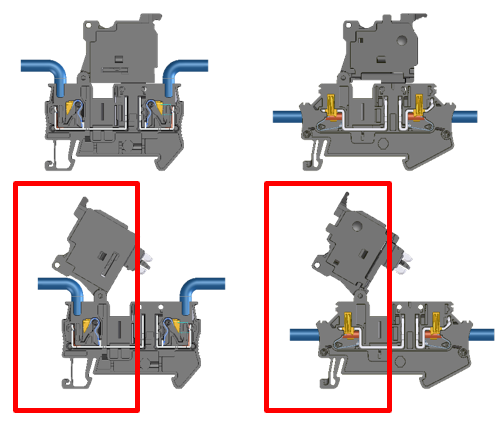

PTV, in fact, is best when it comes to a Fuse terminal block with push-in technology. If you are a user of this, you might have already faced this little situation. When you try to disconnect the fuse holder, the conductor might block you from flipping it over fully. With lateral Push-in technology, you have full freedom of flipping the fuse holder.

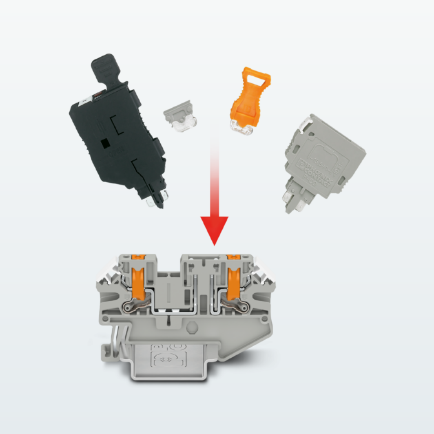

- Best System compatibility

PTV, as a part of CLIPLINE complete, allows you to use the same set of accessories as other CLIPLINE complete terminal blocks with different connection technologies. The list of accessories for disconnect terminal blocks is:

- fuse plugs

- component connectors

- feed-through connectors, and

- isolating plugs

This versatility enables you to customize your switching devices.

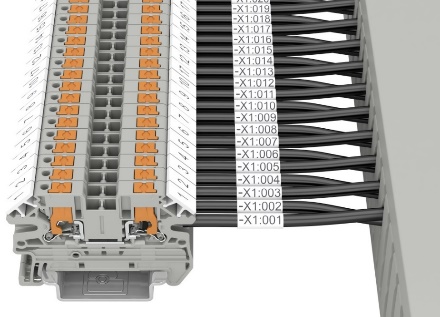

- Best Clarity

The conductors entering from the side will not bend and cover your markings on the terminal block. This also enables easier identification of conductor markings and connection.

Today, you can find the Push-in technology in various terminal block types from normal feed-through terminal blocks to even test disconnect terminal blocks. With our new lateral Push-in technology, we can offer you an even wider range of terminal blocks!