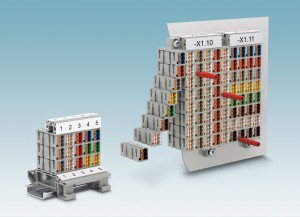

Thanks to the new PTI 4 three-level installation terminal blocks with push-in connection technology from Phoenix Contact, rigid conductors up to 6 mm² can be easily and directly wired without tools. The terminal blocks are specially tailored to the requirements of the electrical installation and the distributor construction, thanks to their compact design.

The snap-in, no-screw disconnect slide with status indicator makes contacting the neutral busbar easy and safe. The function shaft on each level provides for easy potential distribution, thanks to the flexible jumper system. Each terminal point can be clearly marked and, in addition to the testing facility, has its own test connection in the function shaft.

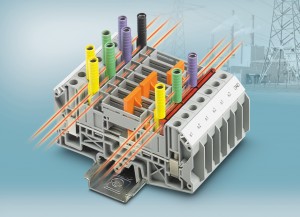

Thanks to the insertion force, which has been reduced by 50 percent, it is possible to insert solid and stranded conductors with ferrules and cross sections from 0.5 to 6 mm² without tools. The built-in actuation lever allows fully insulated release with any tool. The orange-colored button indicates the actuating element. This prevents the terminal from being activated accidentally. Flexible conductors without ferrules can also be connected, from 0.2 mm by actuating the lever.

The push-in three-level terminal blocks share all the system characteristics with the CLIPLINE complete terminal block series and are therefore compatible with all installation terminal blocks from Phoenix Contact.