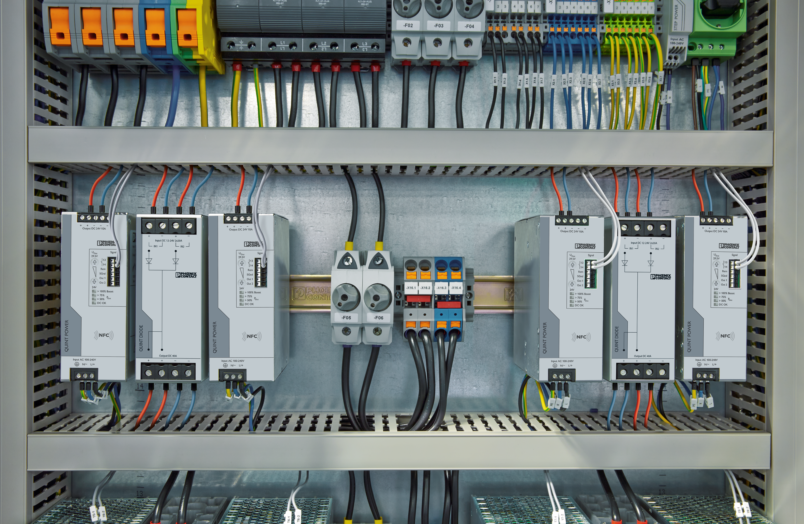

The fourth generation of the high performance QUINT power supply units ensures superior system availability by means of new functions. Signalling thresholds and characteristic curves can be individually adjusted via Near Field Communication (NFC) interface.

The unique Selective Fuse Breaking (SFB) technology and preventive function monitoring of the QUINT power supplies increase the availability of your application.

QUINT 4 power supplies standard products are already equipped with comprehensive diagnostics that provide constant monitoring of the output voltage and output current. This preventive function monitoring visualizes critical operating states and informs the controller of them before errors occur.

Why are the QUINT 4 power supplies called a SMART power supply unit?

Selective Fuse Breaking (SFB) Technology

Even standard circuit breakers can be tripped reliably and quickly with SFB technology and withstand six times the nominal current for 15ms. Faulty current paths are switched off selectively, the fault is located, and important system parts remain in operation.

Example: Normal Power Supply Unit will take around 8-20 seconds to trip the circuit breakers. In this duration, the end device is drawing maximum power from the power supply unit which may cause the end device to be burnt. In this aspect, the QUINT 4 power supply unit ensures that the end device is well protected, thanks to the SFB technology.

Near Field Communication (NFC) Technology

With Near Field Communication (NFC), you are able to set the parameters for the power supplies easily by using a mobile phone or PC, adjusting signalling thresholds (current/voltage/power can be set differently depending on use). This saves time, minimises errors and facilitates customised applications.

Example: In a large scale project, the parameters of the power supply units can be easily set and also duplicate the rest of the QUINT 4 power supply units by using the NFC function. The parameters, MTBF (Mean Time between Failure) and serial numbers of the power supply unit can be displayed on the mobile phone or PC by NFC when it is online without interrupting the operation. Security passcodes can be set to prevent unauthorized personnel changing the parameters of the power supply unit.

Preventive Function Monitoring

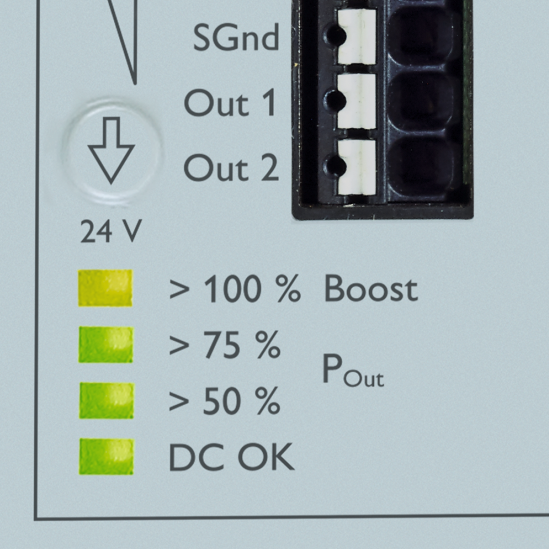

Diagnostics on the bar graph help during operation and maintenance. The user is able to visualize the status of the QUINT 4 power supply unit during maintenance checks. The load current is able to be displayed as a percentage status on the bar graph. This enables the user to upgrade or maintain the panels in the future without using additional measuring tools like multimeters.

Critical operating status can be reported before errors occur. This flexible function is provided by a variety of contact configurations (relay contact, digital signal, analog signal, optical bar graph). These contacts allow the monitoring of output voltage, output current, output power, operating hours, prewarming derating, overvoltage protection and input voltage.

Power reserve

- Easy system extension with static boost with sustained power of up 125% of the rated load current.

- Increase of power for the future without additional power supply unit, which leads to a reduction of extra cost.

- Reliable starting of heavy loads with dynamic boost with up to 200% power for 5 seconds – for components with high inrush current.

Example: When powering up a motor, the initial start will require high power from the power supply unit before going back to its nominal current state. The QUINT 4 power supply unit is able to start this application smoothly without disturbing the other components in operation.

High level of immunity to interference

- Due to an integrated gas-filled surge arrester, the QUINT 4 power supply unit is protected from any transients from the incoming supply.

- More than 20ms mains buffering time – in case of any power dip, the QUINT 4 power supply unit will maintain a suitable output.

- High MTBF > 500,000 hrs – estimation of more than 50 years, assuming 24hours operation.

Worldwide use

- International approval – Class 1 Div 2, IECEX, ATEX, CE, UL, GL, EAC etc.

- Input voltage of 100 – 240Vac or 110 – 250Vdc.

- Automatic switch enables simple plug and play in any part of the world.

QUINT POWER 4 is the power supply that is truly a SMART Power supply. If you have any queries, feel free to contact us at marketing@phoenixcontact.com.sg!