In the previous post, we discussed a little on the origins of IIOT (Industrial Internet of Things) and case studies of how IIOT have helped various industries.

A point to note, is that IIOT was not an initiative that sparked a revolution today. In fact, IIOT is part of a concept which derived from the German idea of “Industrie 4.0”, or rather, the Fouth Industrial Revolution.

Advent of Industry 4.0

The “Industry 4.0” initiative was constructed as a strategic plan by Germany back in 2006 to promote computerization in manufacturing.

In July 2010, the German’s government cabinet decided to accelerate the strategy by introducing the High-Tech Strategy 2020, which aims to focus the country’s research and innovative policy on inspiring projects related to scientific and technological developments over a span of ten to fifteen years.1

Source: https://www.hightech-strategie.de/de/The-new-High-Tech-Strategy-390.php

Germany has certainly come a long way.

The High-Tech strategy can be summarized as moving Germany forward, to become a worldwide innovation leader. By strengthening Germany’s position as a leading industrial and exporting nation, Germany believes that innovative solutions are factors that drive prosperity and increases their quality of life.

Hence, by leveraging on the idea of Industry 4.0, Germany could achieve their long-term goal of High-Tech Strategy 2020.

Back to Industry 4.0

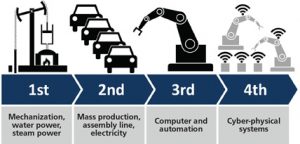

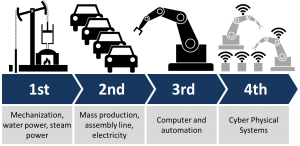

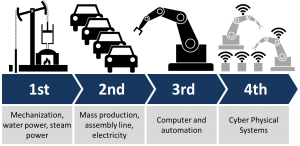

Industry 4.0 is a vision of integrated industry implemented by leveraging computing, software, and Internet technologies. The 4.0 refers to the idea of a fourth industrial revolution:

- First: production mechanization using water and steam power

- Second: mass production (Henry Ford often cited as the innovator)

- Third: digital revolution (e.g., machine tool numerical control, programmable logic controllers, direct digital control, and enterprise resource planning)

- Fourth: Industry 4.0 leveraging cyber-physical systems, embedded computing, Internet of Things technologies.

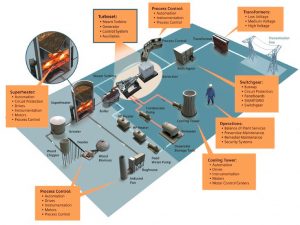

The German strategy highlights cooperation between industry and science to promote closer links between knowledge and skills. In the final report for Industrie 4.0 entitled “Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0”, it describes using Internet of Things technologies, communications, and web services in manufacturing.

It makes it possible to create networks incorporating the entire manufacturing processes, converting factories into smart environments for tomorrow.

Vision for Industry 4.0

Industry 4.0 – The future of industrialization, empowered by technology and the internet

The vision of Industry 4.0 is to achieve higher productivity, efficiency, and self-managing production processes where people, machines, equipment, logistics systems, and work-in-process components communicate and cooperate with each other directly.

The main goal is to produce low-cost mass production to achieve make-to-order manufacturing of quantity by leveraging embedded processing and communications. Production and logistics processes are integrated intelligently, creating a real-time lean manufacturing ecosystem that boasts efficiency and flexibility.

This will help facilitate smart value-creation chains that include all of the life-cycle phases of the product – from the initial product idea, development, production and usage, to maintenance and recycling. This allows the business to constantly make improvements, based on informed decisions.

Industrialization towards 21st century and beyond.

Data derived from the supply chains make it possible to optimize production steps and the entire value chain. For example, comprehensive real-time information enables companies to react during production such as anticipating the availability of certain raw materials based on price, quality, and other factors for optimal efficiency.

Data extrapolated could also be shared across company boundaries, to save resources and energy.

The digitization of industry is forecasted to foster new business models and present great opportunities for small- and medium-size enterprises. Currently, majority of the companies are already adopting this idea.

Benefits of utilizing Industry 4.0

Gone are the days of factory lines.

- Asynchronous manufacturing

Traditional assembly manufacturing lines are synchronous, with predefined workflows based on production work orders running in enterprise business systems. Production steps are centrally communicated to each manufacturing station synchronized by the assembly line.

In Industry 4.0 however, is based on asynchronous manufacturing, with components in the production flow using auto identification technology to inform each machine and operator what needs to be done to produce the customized end product at each step of the production process.

Just like Humans, Machines have to be flexible.

The usage of highly adaptable and flexible machines is another aspect of Industry 4.0. This achieves a highly flexible, lean, and agile production process enabling a variety of different products to be produced in the same production facility.

Profitable mass customization allows the production of small lots (even as small as single unique items) due to the ability to rapidly configure machines to adapt to customer-supplied specifications and additive manufacturing.

Manual Data Entry, a thing of the past. Slower data processing = less productive

Other than relying on flexible and adaptable machines, Industry 4.0 systems capture a wide range of data that can be used to improve performance and productivity through analytics.

Analytics are used in a number of ways, including real-time predictive maintenance, which helps manufacturing companies avoid interruption in production by machine failures—directly improving asset utilization. With analytics, businesses can make informed decisions on production operations, improving productivity and energy efficiency.

Technology, empowering the future and beyond

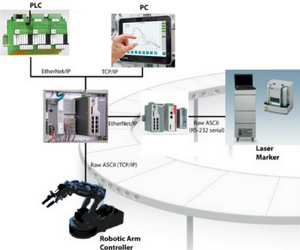

The application of the Industry 4.0 vision is turning into a reality with technological advances driven by the Internet of Things which includes open software platforms, open communications, and powerful embedded processors.

Industry 4.0 uses the term cyber-physical systems (CPS) to describe the interaction of physical and computing, including embedded intelligence at all levels, including machines, sensors, actuators, production parts, subassemblies, and products being produced.

CPS is composed of physical entities, such as mechanisms controlled or monitored by computer-based algorithms. A current example of the application of CPS is mechatronic drive systems that use processors and communications embedded in motor drives to accomplish coordinated operations in a packaging machine without physical gearing. This saves significant cost, providing greater flexibility and improved reliability.

Proliferation of Industry 4.0

The fundamental reason behind shifting towards Industry 4.0 is the realization that pursuing low labor costs is no longer a strategy. Staying competitive and flexible can only be accomplished by adopting the latest technology – in this case, banking on automation.

Historically, if we were to refer to the Second Industrial Revolution, Henry Ford pioneered the assembly line method of producing automobiles.

Automobiles were only available to the affluent back in the days but by manufacturing an affordable car by means of simplifying the process from 12 hours to a mere 93 minutes, Ford, with its Model T, commanded a 48 percent share of the automobile market.

Competitors knew that they had to implement such technology of assembly lines or be at risk of bankruptcy if they could not compete.

With Ford’s revolutionary strategy in 1914, the U.S continued to contribute to 48 percent of the world’s automobile throughout the 60’s. By 1997 however, Japan took over, producing 21 percent of automobiles. The success of the Japanese automotive manufacturers was attributed to advanced manufacturing methods, aggressive automation and widely use of robotics (Currently, Japan has 323 robots per 10,000 people).2

Source: https://ifr.org/worldrobotics

Robots are solving the issue of manpower in Japan

At that time, U.S automakers had access to similar technologies and methods but did not pursue them until compelled by economic factors.

In 2014, Japan had 13 percent share, just below Germany at number 1 at 23 percent. U.S remains at 9%, a shadow of its former self, considering the 48 percent in 1960.3

Source: Harvard Atlas of Economic Complexity

Because of this example, manufacturers around the world are accrediting the success of automation as factors in producing products with precision and consistent quality.

In 2014, China was the single largest market for industrial robot sales. Based on the present rate of robot adoption, within two years, it would be predicted that there will be more industrial robots in Chinese factories working hand in hand with manual workforce than in the European Union or the U.S.

Conclusion

Based on historical data and countless of analytics on the web, as a business, there’s no escaping Industry 4.0 and the Industrial Internet of Things. Businesses must be prepared to usher this new technology and adopt it, if not soon. Competition is high especially with globalization and the need to produce low-cost products at high quality.

In Germany, such initiatives are being supported by the government. Japan, India, and China are following closely behind.

The question is, can Southeast Asia keep up and from it emerge companies who will pioneer new technological innovations?

Interested to find out more? Get in touch with us at marketing@phoenixcontact.com.sg!