Have you ever encountered the following situations?

- Machine stops suddenly due to contaminated sensor/actuator

- Stopping the machine in order to change to another color detection (or other parameters) on the sensor

- Stopping the machine when replacing a faulty sensor in order to set the parameter of the new sensor

What if you can…

- Re-parameterize the sensor without shutting the machine down

- Replace a new sensor with the previous parameters automatically downloaded without shutting the machine down

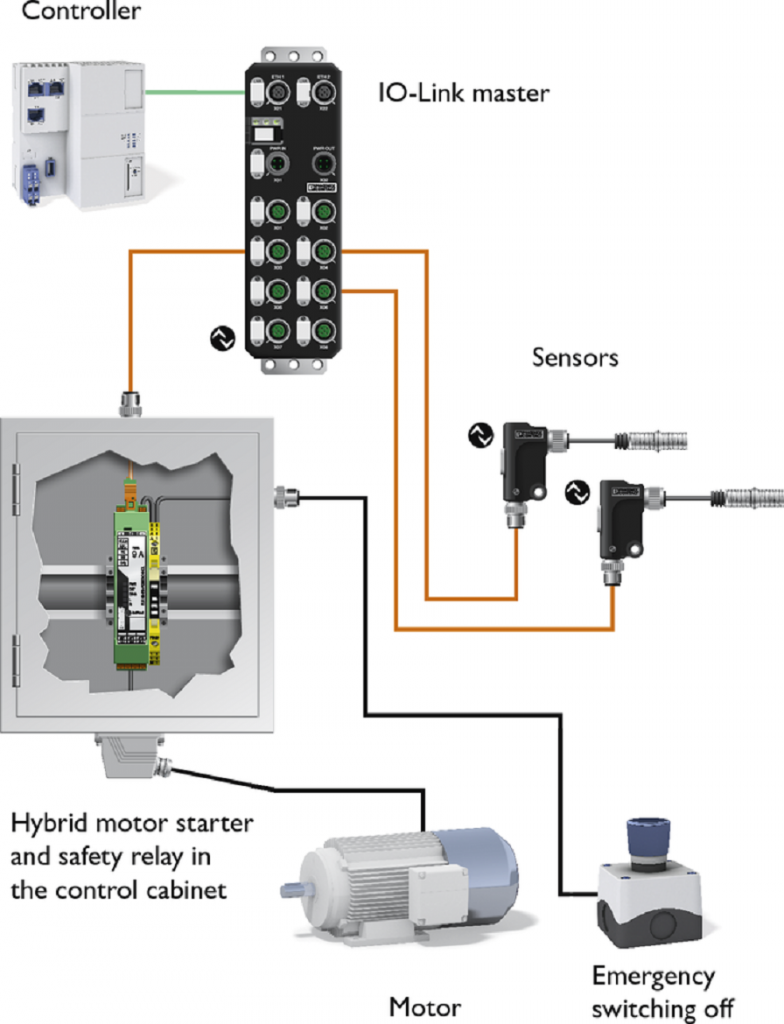

The above is made possible due to the IO Link technology. IO Link is a standardized IO-technology (based on IEC 61131-9) focusing the communication between field devices and sensors & actuators. This enables the exchange of both process data and service data between the connection and sensor/actuator. With the IO Link technology, devices can now identify and configure themselves automatically. This will enable an easy replacement of defective components and reduces downtime significantly.

An IO-Link system consists of the following basic components:

- IO-Link master

- IO-Link devices

- Standard 3-wire sensor cable/actuator cable

Phoenix Contact offers a comprehensive IP20 and IP67 portfolio of IO-Link masters, IO-Link devices, cabling, and software.

If you need further consultation on your next IO-Link application, please do not hesitate to drop us an email at marketing@phoenixcontact.com.sg!

We are all familiar with the computer at home but is your home computer drastically different from the computer used in the industrial world ?

We are all familiar with the computer at home but is your home computer drastically different from the computer used in the industrial world ?