The Mini Analog Pro is the latest and most innovative signal conditioner from Phoenix Contact. It replaces the proven Mini Analog series but with a slew of additional features that will benefit the user and the industry.

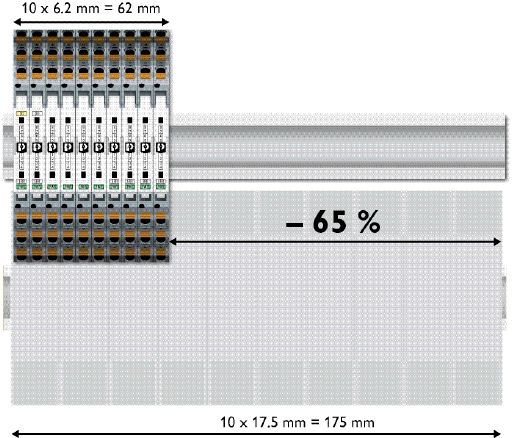

The most advanced feature over its predecessor and perhaps other makers is the introduction of communication adapter. By using the adapter, the user can replace all its hardwire connection to the the analogue cards of the controller with just a simple communication cable. No more overwhelming hardwire from each analog point to each and every signal conditioner. The protocols supported are Modbus TCP and RTU, Ethernet IP and Profibus with more to come in the near future. Besides saving cost, this can save space in the panel as there is no more need for analogue cards. Furthermore, there is also a backbone power supply accesory called the TBUS where one can power up just one of the signal conditioners and all the connecting units in the same row will be powered up. No more overwhelming power supply cables to each individual signal conditioner.

Mini Analog Pro offers additional configuration options compared to most, if not all, of the other signal conditioners in the market, which can only be configured with the laptop or dip switch setting which requires the accompanying data sheet for reference. More frequently than not, engineers are met with situations where it is inconvenient to bring the laptop to site, or worse, unable to find the configuration cable when you need it. If one is not using Mini Analog Pro, this will means one has to delay the work, thus affecting productivity. With the latest Mini Analog Pro, one can use a smartphone with NFC technology to perform the configuration. The software is easy to use and can be pre-downloaded from the Google PlayStore in preparation for sites where internet connection is not available.

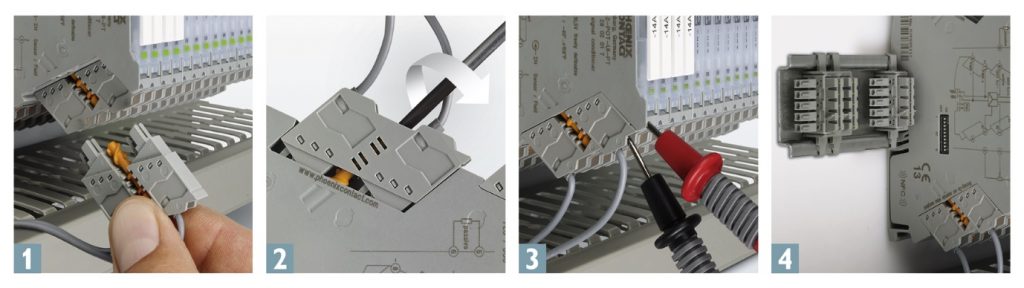

There are times when one has to measure the current values of field devices that are in operation for verification or troubleshooting. With the previous version or with signal conditioners from other makers, one would have to disconnect the cables in order to prevent parallel connections that will affect the actual reading. This adds extra work and effort. The user can now measure the current directly without removing the cables. This is realized technically with the Mini Analog Pro by integrating a diode into the circuit and therefore, parallel measurement is now possible with great accuracy.

Even when one has to absolutely remove the cables due to safety or space issues, the Mini Analog Pro offers an innovative alternative. Each module comes with 4 connection blocks for respective input, output or power supply connections. The connection blocks can be removed easily by using a screwdriver to twist the orange lever above or just by pulling it with moderate force. In this way, the connections are still in the individual blocks and can be reconnected back easily without any need to screw each of the individual cables again. Mistakes can also be avoided because all four of the connection blocks in the signal conditioners are fail safes. Only the right connection blocks can be fitted in its rightful place. Imagine if one does not have this feature and if all cables are disconnected, one would have to check and screw all of them back accordingly.

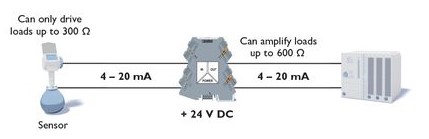

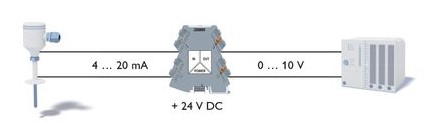

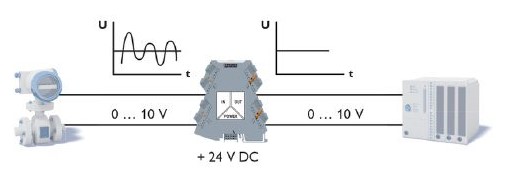

The Mini Analog Pro also has much improved signal quality due to the highest level of galvanic isolation. This increases the accuracy, making it more suitable for the increasingly demanding industry requirements. Furthermore, it has been subjected to 3kV test voltage and 300 V rated insulation voltage. This test ensures that the isolation properties are tried and tested before being deployed in the field. The temperature range it can operate in has also been extended. It can now perform perfectly within the range of 40C° to 70C°. This allows reliable operation in harsh environment.

These innovative features make the Mini Analog Pro one of the most advanced signal conditioners in the market now. These features not only make it easier for the user to work, but also increases the safety, performance and the overall project cost savings.