CEO Chairman of the Board, Mr. Frank Stürenberg

“In 2016, Phoenix Contact could generate a sales growth of 3.2 percent. Compared to the industry surely not bad. However, our planned target of six percent could not be achieved also due to exchange rate effects,” CEO Chairman of the Executive Board, Frank Stührenberg, explained Phoenix Contact´s economic development in the last year at the press conference.

With it, the turnover of the Company Group increased to 1.977 billion euros.

“In Italy, Russia and India for example, we could achieve a very positive sales growth between 12-17 percent,” Stührenberg explained the diverse market development.

Thanks to the dynamic growth in the electromobility market, the subsidiary Phoenix Contact E-Mobility even achieved a sales growth of 70 percent”.

The manufacturer of industrial electronics invested 150 million euros in the development of the Company Group in 2016. 500 new employees joined the company last year.

“In Italy, Russia and India for example, we could achieve a very positive sales growth between 12-17 percent,”

For the current year, Phoenix Contact expects an increase in turnover of around 6.5 percent.

Stührenberg is confident: “In the first quarter of 2017, we have already recorded a very good increase in sales of more than 12 percent. In 2017, we will exceed the 2 billion euros threshold”.

Around 150 million euros will be invested in the national and international development by the company also this year.

At the site in Milan, Italy, for example, additional sales and training capacities with approx. 6,000 m2 will be established.

In India, the production and logistics capacities will be expanded with an investment of 5 million euros.

“In 2017, we will exceed the 2 billion euros threshold”

At the site in Blomberg, the size of the laboratory of Phoenix Testlab, the test lab and certification institute for technical products will be doubled to 4,000 m2.

Also, shares in companies are increasingly included in the investments. At the beginning of April, the company took over Mauell Netzleittechnik GmbH from Velbert to 100 percent. With the integration of the automation specialist in energy networks in the Company Group, Phoenix Contact continues its sustainable growth strategy in the energy market.

Just recently, Phoenix Contact has also taken over the Taiwanese company Etherwan System Inc., a manufacturer of Ethernet communication technology in automation.

Both companies have already successfully cooperated for 15 years.

With it, Phoenix Contact significantly strengthens its network technology, a key technology for digitalization.

In February, the Phoenix Contact Group took a share in SmartB Energy Management GmbH, a start-up company for energy management in commercial buildings from Berlin via Phoenix Contact Innovation Ventures GmbH. Their software solution makes energy consumption transparent up to the device level.

On April 24, the Hannover Messe which is seen as a trend indicator of the economy will start. This year, the partner country will be Poland. “Our production site there has become the largest production site outside Germany and is the center for the production of modular terminal blocks and cabling solutions,” Stührenberg explained the importance. “Our site in Nowy Tomysl is the major employer in the region.”

This year, the partner country will be Poland. “Our production site there has become the largest production site outside Germany and is the center for the production of modular terminal blocks and cabling solutions,” Stührenberg explained the importance.

“Our production site there has become the largest production site outside Germany”

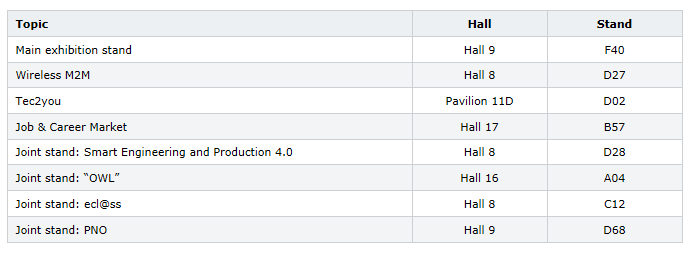

Phoenix Contact as the solution provider for electrical engineering, electronics, and automation will present its innovations and trend-setting technologies in Hannover on an exhibition area of approx. 2,500 m2.

At the heart of the exhibition appearance, there are solutions for the digitalization which focus on the task fields of Industrie 4.0 such as easy operation, secure communication, adjustability or a seamless digital description of the products.

With the open control platform PLCnext, which is the focus of the presentation in Hannover, Phoenix Contact initiates a paradigm shift towards open source-based control solutions for Industrie 4.0.

“Traditionally, the Hannover Messe is the most important trade fair for us,” Stührenberg confirms. “This year, we will present more than 100 innovations and welcome visiting delegations from 50 countries with more than 1,200 visitors”.

As the year of 2016 is ending very soon, it is also the time to review the year’s performance, there is a growing trend that many companies are abandoning the traditional performance reviews. However recent researchers found that formal performance reviews still hold an important aspect for both supervisor and subordinates to make sure that they are on the same page about each other expectation. Instead of ditching the performance appraisal process, more importantly, how do we make the process more purposeful? The guidelines as follows:

As the year of 2016 is ending very soon, it is also the time to review the year’s performance, there is a growing trend that many companies are abandoning the traditional performance reviews. However recent researchers found that formal performance reviews still hold an important aspect for both supervisor and subordinates to make sure that they are on the same page about each other expectation. Instead of ditching the performance appraisal process, more importantly, how do we make the process more purposeful? The guidelines as follows:

technology. This standardisation provides many advantages that can also be used for the solar industry. The Solarworx function block libraries are optimally tailored to our Inline and Axioline automation systems. For the user, this means less complex and more functions during planning and implementing solar projects. Training times and therefore costs can be kept low and system documentation becomes more transparent.

technology. This standardisation provides many advantages that can also be used for the solar industry. The Solarworx function block libraries are optimally tailored to our Inline and Axioline automation systems. For the user, this means less complex and more functions during planning and implementing solar projects. Training times and therefore costs can be kept low and system documentation becomes more transparent.