The Association of Southeast Asian Nations (ASEAN) is predicted to become the fourth-largest economy in the world by 2030, after the United States, China, and the European Union. The regional development is pushed by a growing educated and young workforce, coupled with a jump in manufacturing Foreign Direct Investment (FDI) across ASEAN member countries.

Against the backdrop of this shift in production capacity to this region, governments in ASEAN are encouraging the adoption of 4th Industrial Revolution technologies (e.g. industrial robots, artificial intelligence, data analytics) through various initiatives to support producers of relevant technologies.

Our Machine Building Heritage

Since 1968, Phoenix Contact has been operating an in-house machine building department at Blomberg to maintain our independence from service providers. Today, this department of 260 employees provides support for all developmental and manufacturing business units worldwide. The service portfolio has started to shift from creating manually operated equipment to complex production systems. We are, therefore, very familiar with your daily challenges in this transformation process.

Robust solution to avoid costly downtimes

Tapping into the experience gained from the past decades, the following points have been identified when developing machines for our own production facilities:

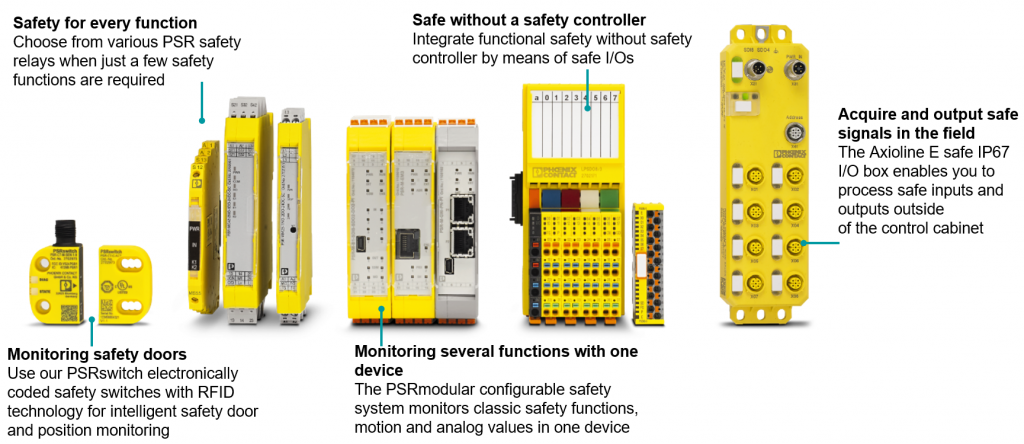

Machine Safety – Safety technology is paramount in machine building. It prevents operating staff from being put at risk or damage being caused to the machine. Phoenix Contact’s comprehensive portfolio ranges from non-contact safety switches and safety relay modules to network-capable safety solutions. All our products are very easy to install and configure. This allows you to benefit from the fast and cost-effective implementation of safety-related applications.

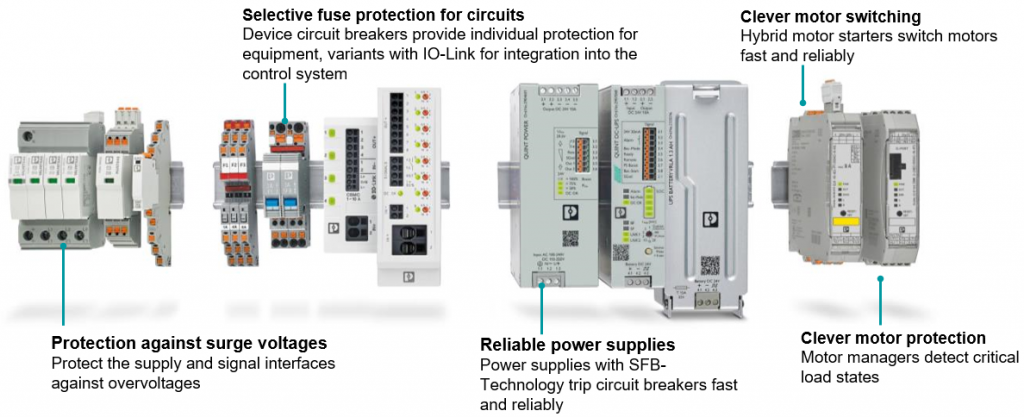

System Reliability & Availability – There is nothing costlier than having a machine that is down. Downtimes ultimately lead to production losses and incur extremely high costs. This makes machine availability the top priority. Reliable components and high machine availability are crucial in preventing downtimes and production losses.

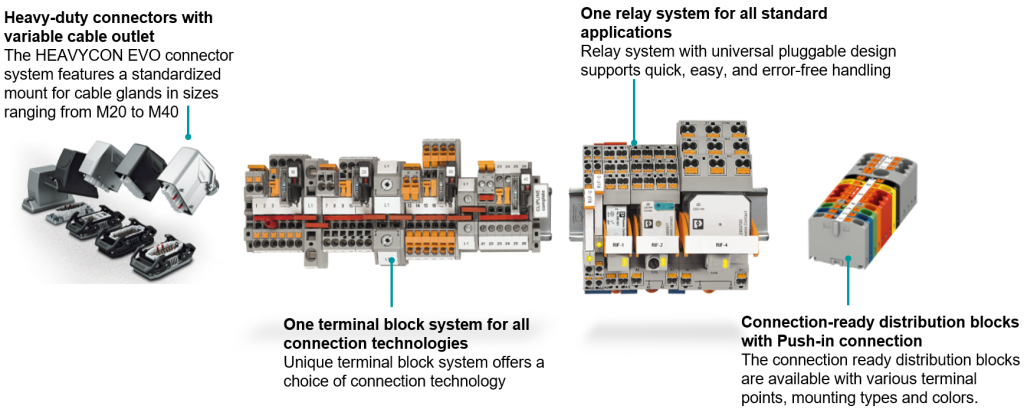

Ease of Installation & Servicing – Today’s machines must be able to quickly adapt to changes in the market. A modular machine concept guarantees maximum possible flexibility, while optimally coordinated product solutions are the key to keeping machine manufacturing costs as low as possible.

Utilising components with universal accessories allow a significant reduction of parts and lowering of storage costs. Such standardization simplifies start-up and maintenance for your installation engineers and service technicians.

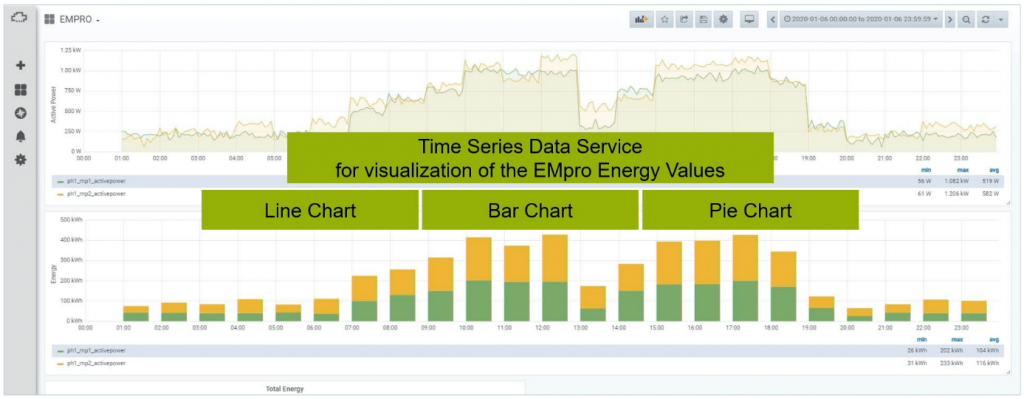

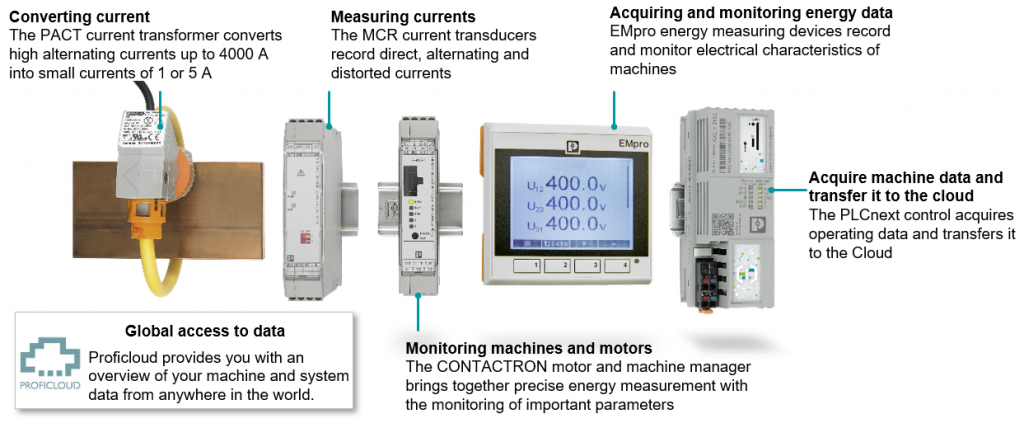

Reliable Data Acquisition through Cloud

To maintain the competitive edge in the market, processes must be as efficient as possible and continuously improved. Decisions regarding the optimization of machines and production processes are made based on machine and system data.

The collection and evaluation of values such as flow rates, currents, or temperatures allows predictive maintenance to be carried out, thereby improving machine performance and reducing machine downtimes.

Your technology partner towards Smart Manufacturing

Making the Global Reach – Enhancing the value proposition further, the data collected can be pre‑evaluated using a PLCnext Control device and easily transferred to the Cloud. This means that you have an overview of your machine data anytime, anywhere, for optimum machine utilization and availability.