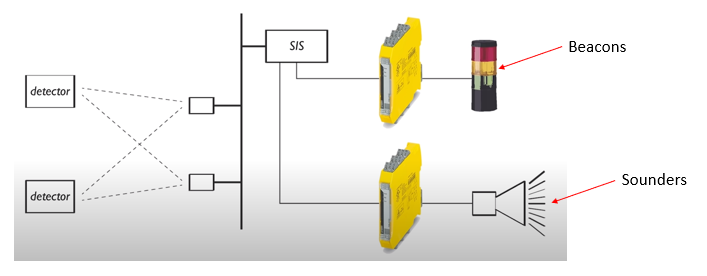

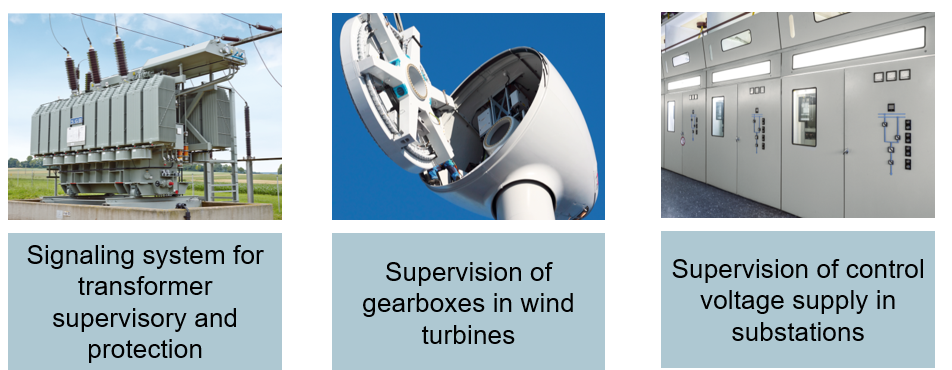

Annunciator relays are used to indicate dangerous states and operating states in control rooms, on control panels, and in mimic diagrams. The annunciator relays from Phoenix Contact feature a convenient display area and ensure reliable operation thanks to their robust construction. They are therefore also suitable for use under harsh ambient conditions.

Semi-automatic annunciator relay

The Mauell MR 11 annunciator relay is a semi-automatic relay. Apart from the coil excitation voltage, no other auxiliary voltage is required for the visual display. This is particularly important in voltage monitoring applications. The indicator flag area is black during normal operation. The white text field appears when the relay has been triggered. The contacts also switch to the operating position. The message is acknowledged by pressing the reset button on the device front. Once the message has been acknowledged, the text field remains visible, and an additional red-white hatched indicator flag is displayed. The contacts return to the normal position. Once the malfunction has been cleared, the indicator flag automatically returns to the normal operation position. In addition to the contact function described, additional contacts can be switched directly. These contacts operate independently of the acknowledgment function. The required switching action – normally open or normally closed – is set at the factory and can be changed later.

Fully automatic annunciator relay

The Mauell MR 21 annunciator relay is also used to indicate dangerous states and operating states. It is fully automatic and there is no manual reset function. Depending on the switching action, the relay switches to the triggered position when energized/de-energized. This switches the contacts and the indicator flag marking appears. Once the malfunction has been cleared, the indicator flag automatically disappears. The contacts also return to the normal position. The required switching action – normally open or normally closed – is set at the factory and cannot be changed later.

Designs

A general distinction is made between the three designs: surface-mounted, flush-mounted and combination:

Surface-mounted

The relay includes a DIN rail fastener (35 mm) with connector plate and clamp.

Flush-mounted

This design is for switch panel mounting with clamping frame. The contact protective cap conforms to BGV A3.

Combination-mount

This design is for annunciator relays to be accommodated in one combination housing.