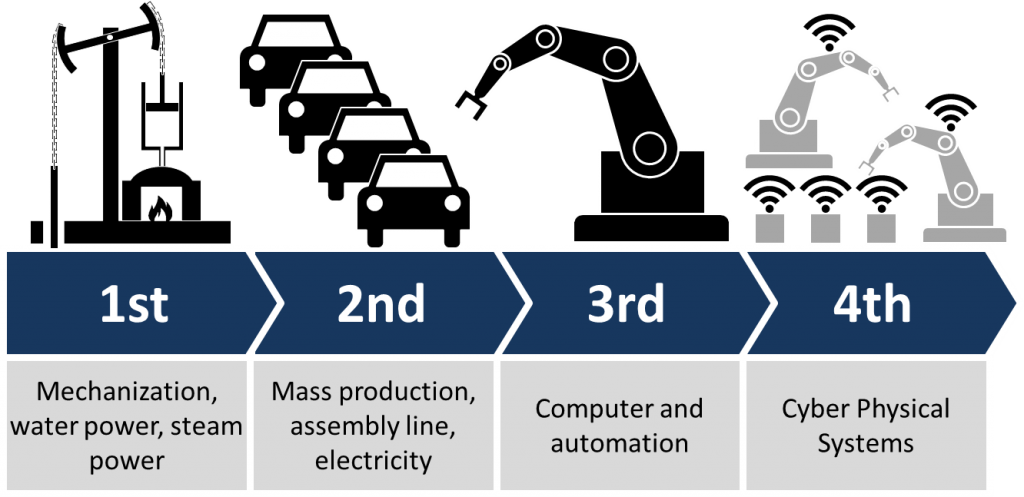

We have entered the 21st Century with the birth of the Industry 4.0 era. But what exactly is Industry 4.0? There are interpretations out there such as Smart Factory, Internet of Things, Industrial Internet of Things, Cloud Computing, Big DATA and Digitalization etc. It is observed that many corporations and business entities are on overdrive budgeting capex and formulating plans to adopt and embrace Industry 4.0.

For most industries, what are the tangible and intangible benefits of digitalisation or achieving Industry 4.0? In the market, it has been revolving around these familiar hot topics: asset management, remote monitoring, machine learning, artificial intelligence, predictive maintenance to achieve world class operational excellence. In fact they are all based on 1 thing – Data. Data sets the precedence for the above. For new plants, the architecture of connectivity can be designed before construction to achieve the ability to harvest all necessary data into a single historian or platform, therefore implementation will be an easy feat. However, existing bases/plants have to face umpteen challenges.

Although existing plants do have sensors/devices that collect data, they are kept to a closed loop industry system. Moreover, a lot of the data/information collection is very manual, such as via maintenance crews going on site using handheld tools for measurement and manual recording. Compared to a new plant, it is not operationally as well as economically feasible to pause operations of an existing plant and overhaul the whole connectivity/system architecture to allow more data flow to enable Industry 4.0. Therefore, without affecting present operation, to modernise an existing plant, a suite of smart devices is required to design a solution to help them realise Industry 4.0.

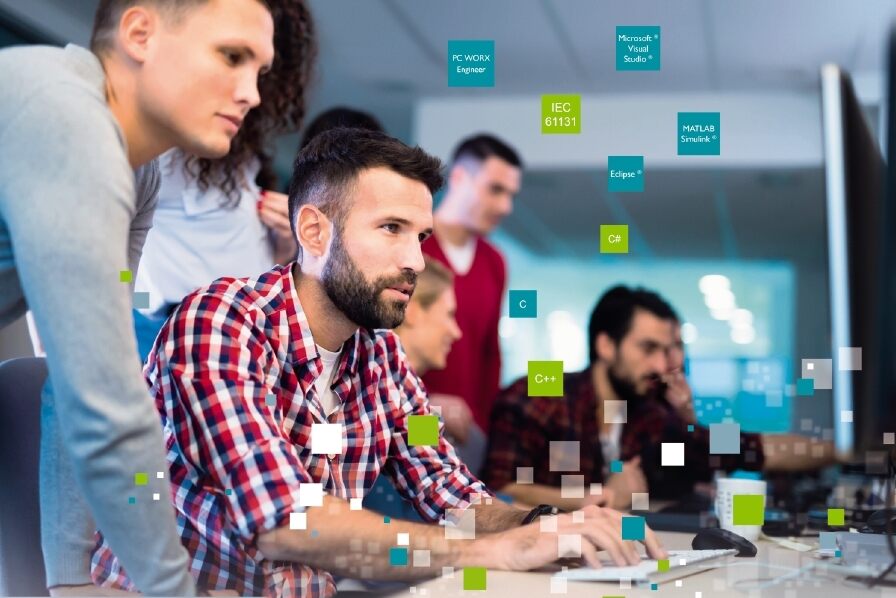

Very often, existing plants have old systems and devices running on various communication protocols, therefore it is always a challenge to harmonise and standardise the data collected. Moreover, additional devices and sensors are also required in the modernisation journey and that will increase the need for I/O points. Phoenix Contact can help clients overcome these challenges in modernising their existing plant and embarking on their digitalisation / Industry 4.0 journey, through the use of one of Phoenix Contact’s leading technologies: the PLCnext Technology. It can provide a very scalable and flexible solution that enables edge computing, possesses the ability to be an OPC UA server, provides a seamless integration of both IEC61131 and High Level Language(HLL) programming, and most importantly cybersecurity is an inherent feature of the PLCnext Technology. With these attributes, it provides an excellent platform to collate and share data on open communication protocols.

Bundled with Phoenix Contact’s comprehensive portfolio of communication interface technology, such as gateways, wireless technology, ongoing partnership development for 5G technology as well as in house technical know-how and expertise, an enhanced connectivity one stop solution can be actualised through partnership with Phoenix Contact. This can help end users for both new and existing plants congregate all required raw data for further data manipulation such data analytics, machine learning or even Artificial Intelligence. The PLCnext Technology Platform has set itself as a gravity centre of a solution of limitless automation / Industry 4.0 Ideas.

For those who wish to embark on a digital journey of Industry 4.0, Phoenix Contact can be there to be your reliable partner.

At present, control applications focus not only on reliability but also flexibility. Following current automation trends in automation 4.0, many vendors will need to improve market share in this market segment.

At present, control applications focus not only on reliability but also flexibility. Following current automation trends in automation 4.0, many vendors will need to improve market share in this market segment.