Box by box towards Smart Grid 1: LV Compartment for MV Switchgear

The gradual shift towards the much vaunted Smart Grid structure has been gathering steam in the last few years. While much of the excitement has been generated from the immense potential of what a fully completed Smart Grid system can bring (for example, higher reliability at reduced cost), Grid operators, independent power producers and their team of engineers are facing real difficulties in implementing such systems today. It is easy to talk about wanting to implement technologically advanced systems, but when it comes to actually executing the projects to implement such solutions, the complexity surrounding such implementations comes to the fore.

Much of this complexity arises because of the vast variety of applications within the industry. It is particularly difficult to find the right set of products that are suitable for the application, reliable, fast to set up and easy to manage. For example in Transmission and Distribution substations, there will minimally be systems for transformers, shunt reactors, switchboards, intrusion detection monitoring systems and each of these systems can consist of smaller sub systems. For example, in monitoring a switchboard, we can monitor downstream load current for energy balancing; micro current fluctuations for signs of partial discharge or even for predictive maintenance; door contact monitoring for physical security and the list goes on. Each of these systems will require the right set of products and will have to be linked in this web of madness. Imagine the chaos!

At Phoenix Contact, we recognise this difficulty. While we have many solutions for Energy Industry that we are always sharing with the various stakeholders, in this series of blog articles, we will be examining how we help to simplify the implementation of Smart Grid. We will do so by examining the building blocks of a system – the individual panels which form up a system; and we will do so box by box. This first article will be about LV Compartment of MV Switchgear and we will delve straight into the 3 problems switchgear builders and grid operators are facing!

Problem 1: How do I collect signals from my switchgears and transform it into IEC61850?

The completed substation topology will involve decentralised controls where IEDs are placed at high voltage equipment (on transformers and switchgears) itself. Even when it is not completed, communications from the bay control cabinets and protection devices to the substation control system are being converted to IEC61850 as IEC61850 has proved to be a superior communication protocol and standard to reduce downtime and increase reliability of the grid. Therefore, it is only a matter of time before all switchgears are converting signals from the circuit breakers and all other auxiliary signals into IEC61850 data. However, examining the LV compartment of switchgears today, the signals are still being passed out with many copper wires or connected to numerical relays. These present two clear drawbacks:

- There are a lot of copper wires going out of the panel or into numerical relays. The associated cost includes requiring marshalling or pilot cabinets and related components and regular maintenance to check if the connections are good. In addition, it is difficult to isolate where the fault is when there is a loss of signal. In the worst case scenario, there might even be accidental shorting resulting in severe downtime!

- Numerical relay and its I/O cards are expensive.

These result in higher initial cost and higher eventual maintenance cost with downtime not necessarily minimized, especially in the event of loss of signal.

Using of a Bus coupler capable of communicating via GOOSE and MMS will solve both of these problems. Using Phoenix Contact bus coupler as an example, the signals can be easily inserted and aggregated as IEC61850 data. It certainly reduces the number of cables leaving the cabinet and with the light indicators, you can see clearly which connections are good without requiring extra tests. It is also of lower cost compared to numerical relays’ IOs while communicating perfectly with them.

Problem 2: There are too many wires, how can we manage them better?

Being the founder of the original ceramic terminal block, it is already tempting to say that Phoenix Contact is the best at solving this! But in the last few years, we have developed more data connectors to put us in a better position to solve this for switchgear builders!

We have an extremely wide range of terminal blocks for every applications and needs. We have demonstrated to be able to meet each and every customers’ unique demands, be it requiring pluggable solutions, fastest connection technology, space saving, you name it, we’ve done it!

In this article, we would just like to highlight how a commonly used connector for switchgears has developed to adapt to Smart Grid. In the past, our Heavycon (heavy duty connector) was often sold to connect the LCC and Bay cabinets. This enabled quick connection on site.

However, these connectors are usually for loose copper wires only. Although you can strip an Ethernet/serial connector to use such connectors, these connectors does not cater very well for the shielding required for data connector. Therefore, Phoenix Contact has developed a modular connector, allowing you to use your data connectors directly! This modular connector even allows you to have connectors which allow for high power!

Problem 3: With more signals being collected, there will be more testing to be done. How can we ensure we are safely doing the testing all the time!

Every so often, testing needs to be done on the current transformers and voltage transformers regularly. For current transformer especially, if not done right, explosions can happen. Currently, the shorting and breaking of circuits are done manually by hand (yes you read that right) and as you can imagine, explosions lead to death.

To solve this, Phoenix Contact has developed our test disconnect system (FAME) where shorting is done automatically and it is fool-proof!

Instead of using terminal blocks that are switched manually, you can replace it entirely with FAME and from then on, every testing procedure will be done how it is meant to be done: SAFELY.

We have assembled this product into a demo box along with other products that Phoenix Contact offers for LV Compartment for MV Switchgear. If you will like to have a look at the demo box up close, do contact us at marketing@phoenixcontact.com.sg and we will get in touch!

We have assembled this product into a demo box along with other products that Phoenix Contact offers for LV Compartment for MV Switchgear. If you will like to have a look at the demo box up close, do contact us at marketing@phoenixcontact.com.sg and we will get in touch!

We have assembled this product into a demo box along with other products that Phoenix Contact offers for LV Compartment for MV Switchgear. If you will like to have a look at the demo box up close, do contact us at marketing@phoenixcontact.com.sg and we will get in touch!

We have assembled this product into a demo box along with other products that Phoenix Contact offers for LV Compartment for MV Switchgear. If you will like to have a look at the demo box up close, do contact us at marketing@phoenixcontact.com.sg and we will get in touch! Phoenix Contact has been serving the railway industry for decades, especially for rolling stock and signalling. Safety and reliability has always been our number one concern when developing products for railway applications.

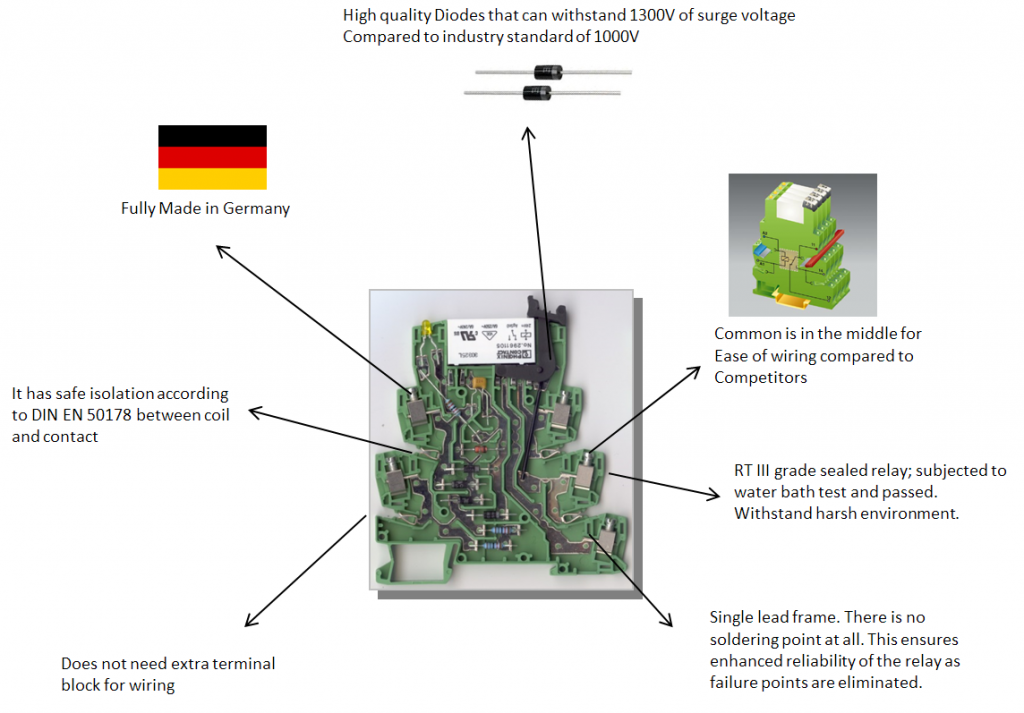

Phoenix Contact has been serving the railway industry for decades, especially for rolling stock and signalling. Safety and reliability has always been our number one concern when developing products for railway applications.

Are you selecting a safety relay just to meet the SIL3 requirements?

Are you selecting a safety relay just to meet the SIL3 requirements?