Most of us should know that there are 2 main categories of network switches, the Unmanaged Switch & the Managed Switch. However, sometimes we struggle to understand when to use a managed switch.

In this article, we will look at 3 key reasons why a managed switch is required in a network topology. Hopefully, after this, you can make use of these 3 key reasons to identify when a managed switch should be used.

Reason 1 – Building network redundancy

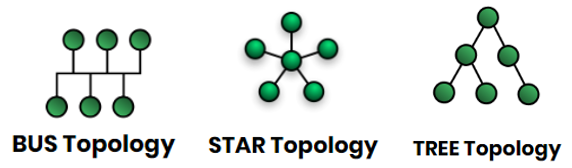

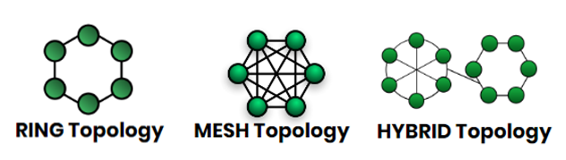

Not every type of network topology provides a redundancy mechanism. And what that means is that they will often have a single point of failure – where if one network switch fails, it will stop the entire network from working. Some examples of network topology without redundancy include Bus, Star and Tree etc.

To provide more than a single point of failure, network topology with redundancy mechanisms such as the Ring, Mesh and Hybrid must be used. Managed Switches can support such network topologies through different network protocols. Examples of the protocols include Media Redundancy Protocol (MRP), Rapid Spanning Tree Protocol (RSTP), etc.

Reason 2 – Acquire and provide data for network diagnostics

As Lord Kelvin puts it, “To measure is to know. If you cannot measure it, you cannot improve it.” Similarly, we need to know the diagnostic data of our network topology, to understand its status and improve it.

A Managed Switch provides important information that can help us to monitor the network topology and call for maintenance before full failure of the system happens. This could be classified as predictive maintenance, which brings great reliability benefits.

Some key diagnostic information includes:

- Port connection status

- Redundancy connection status

- Power supply status (Interruptions)

The acquisition of these information could also be achieved through different automation protocols such as MODBUS, Profinet, Ethernet/IP etc.

Reason 3 – Security features

Managed switches offer security features such as user-interface & port security.

A user-interface security prevents any unauthorised access into the switch management and configuration. While port security allows only devices with a registered MAC-address to send and receive data packets through the network switches.

Summary

There are many other applications of Managed Switches, such as the use of Layer 3 & VLAN applications, which are critical for big networks. In Phoenix Contact, we provide a good range of network switches for different applications that you might have. Find out more in the following link or contact us at Phoenix Contact SEA.