Many of you may be familiar with our next gen PLC called PLCnext, but how easy is it to actually make the switch? Today, I would like to share with you from a fresh perspective – that of a Phoenix Contact intern who has been learning to use PLCnext Technology for a mere two months.

As someone who has taken a few programming-related modules in university, I thought I had at least heard of most of the programming languages. However, when I first started learning about PLCnext, I was introduced to IEC 61131-3.

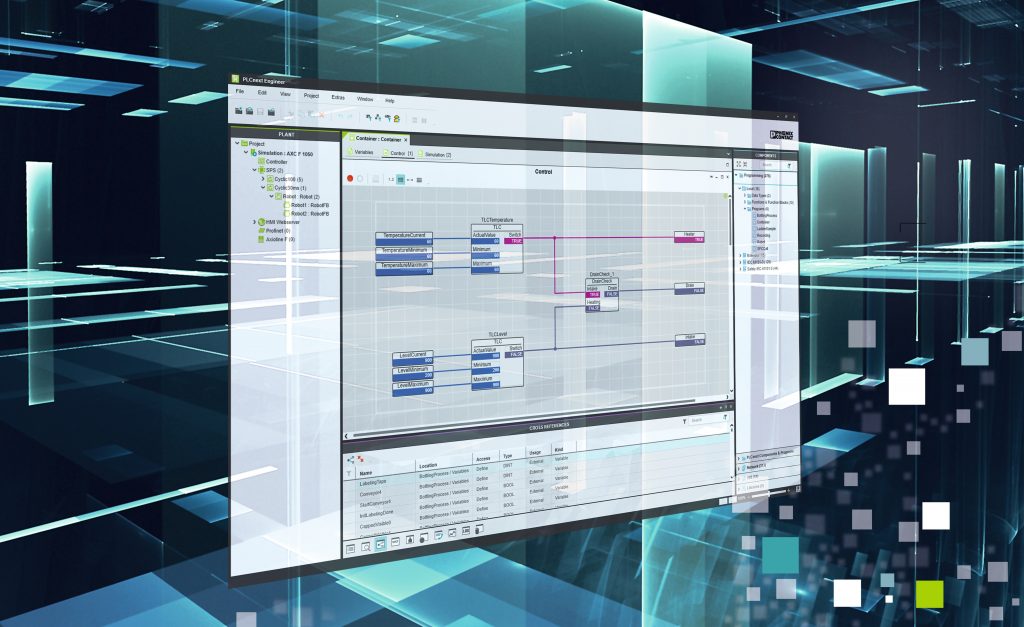

IEC 61131-3 is the standard for dealing with programmable logic controllers (PLC). The software used to configure PLCnext controllers, called PLCnext Engineer, mainly uses 3 PLC programming languages:

- Function Block Diagram (FBD)

- Ladder (LD)

- Structured Text (ST)

Once again, I had never worked with any of these languages before in my programming modules. FBD was relatively easy to pick up, as the default function blocks in PLCnext Engineer provided more than enough functionalities for my internship project. The FBD editor was also extremely user-friendly. It also had the capability to change variables on the fly using Debug Mode, which made troubleshooting a real breeze.

And yet, FBD was not a language I was familiar with. If you have learnt a new language before, you may have experienced times when you cannot express yourself or cannot translate your thoughts from your native language to the new language you are learning. Thankfully, that is where the prowess of PLCnext Technology comes in.

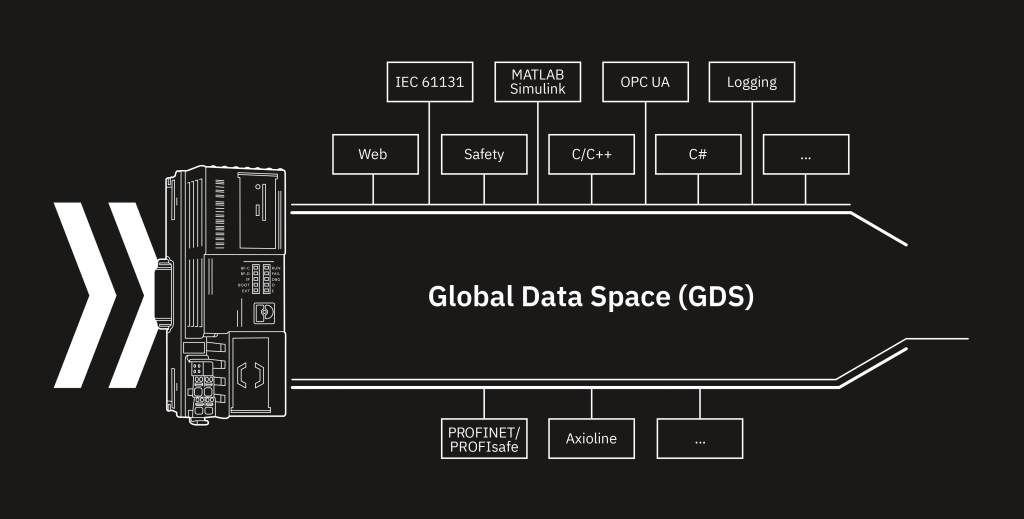

To make things short and sweet, PLCnext Technology essentially allows the use of different languages for programming of PLC logic. Instead of using IEC 61131-3 languages for the main program logic, languages such as C, C++, C# and MATLAB Simulink can be mapped to the IEC 61131-3 code. This is possible through a Global Data Space (GDS) which maps input and output ports of IEC 61131-3 languages with that of the other languages being used.

What this essentially means is that many people who are familiar with different programming languages can work on the same project! PLCnext Technology bridges this gap between programming languages, making automation that much easier.

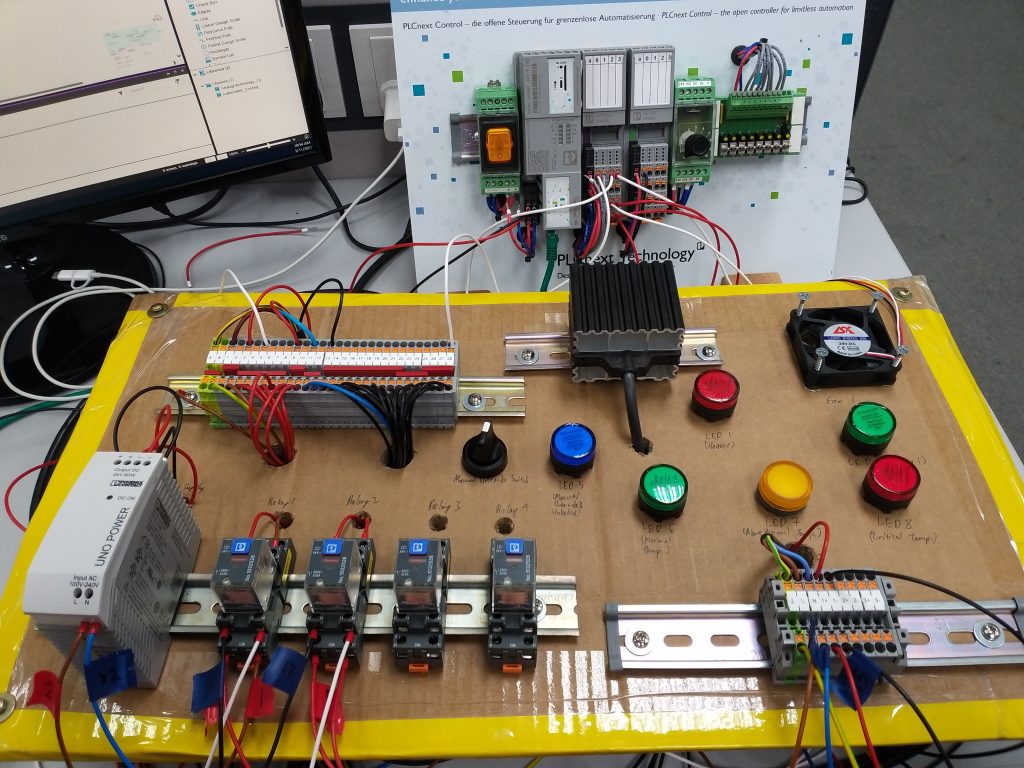

That being said, some (extremely) basic knowledge of at least one of the IEC 61131-3 languages are required. However, this was easily picked up after I was loaned the AXC F 2152 Starter Kit to practice.

Two months into my internship, and I have already learnt enough to build a small-scale prototype of my final project. While I will not be delving into the details here, the important part is that majority of the logic is coded in C++, instead of IEC 61131-3 languages.

If an intern can whip up something like this from scratch in two months, I am sure you can too!