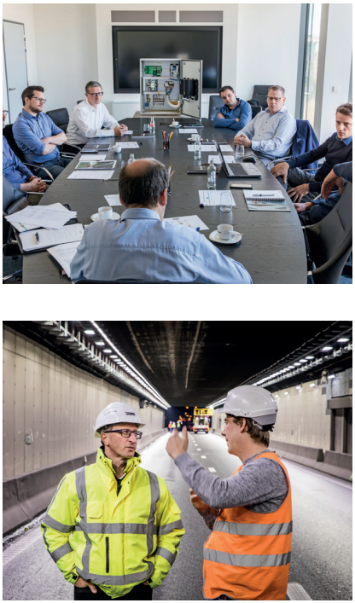

Vierarmen Tunnel – Belgium, is a 540 metres long tunnel which underwent a massive relighting project of more than 1,400 light modules. Advanced Automation was also implemented to enable remote operation and monitoring of the new LED tunnel lighting.

By replacing the old fluorescent and sodium lights with LEDs, the primary objective is to achieve energy savings. The longer service life of LED lights also means less maintenance is required, which translates to less holdups for road users.

Every effort was made to minimise inconvenience caused by the lighting replacement. The replacement work was completed in 45 nights per tunnel shaft, all thanks to the advance preparation and the simplicity of the plug-and-play system.

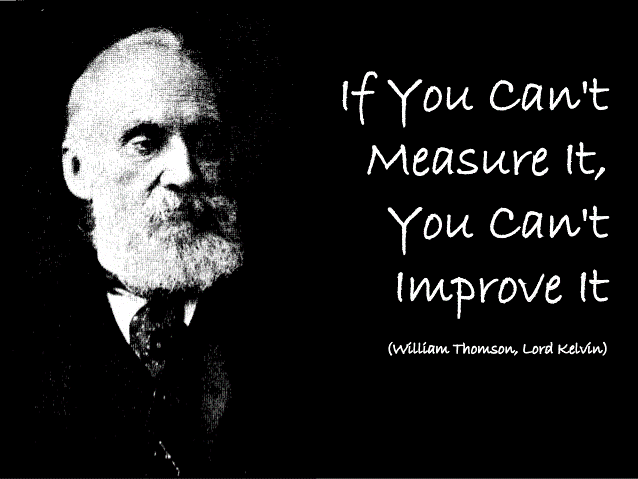

Good Collaboration

The replacement of the lighting in the Vierarmen Tunnel was carried out by the VSE – ENGIE Fabricom joint venture. Lighting systems from the Belgian manufacturer Schréder were selected.

Phoenix Contact supplied the Tunnel Control System and dealt with the implementation of the plug & play concept. Lastly, Tein Technology was the supplier of the central operating and monitoring system of the Flemish tunnels in the control room.

Every aspect of the installation was optimally coordinated to finally arrive at a reliable solution and to permit the installation of the system to occur smoothly and efficiently.

Minimum Energy and Maintenance

At the entrance to the tunnel, 300 candela per square metre is required. This entrance luminance is achieved by means of TAG lighting equipment.

Steven Hulpiau: “Because the light fittings can only be positioned on the side wall of the tunnel in this case, we are using special lenses that scatter the light beams to the side. In this way we can guarantee the required brightness everywhere in the tunnel with a minimum of energy. An additional saving arises from the fact that the lights can be dimmed.”

The electronics that control the lighting and that are normally located in the light fittings were in separate “driver boxes” installed right next to the light fittings. The advantage of this is that the light fittings do not have to be opened if maintenance needs to be performed on the electronics later.

Tunnel Control System

Tunnel Control System from Phoenix Contact is the beating heart, which consists of a controller, I/Os and communication modules that are used worldwide in tunnel projects.

The electronic control of the lighting makes a whole range of options and scenarios possible. To start with, there is the difference between daytime and night-time mode with lights that can be dimmed or switched off at night. The brightness control considers the sensors for measuring the luminance at both entrances to the tunnel. The aim is to guarantee sufficiently bright lighting with as little energy consumption as possible.

Plug & Play

For the new lighting installation to be carried out smoothly, various parties on the project collaborated on a plug & play concept.

Phoenix Contact’s QPD connectors were selected for the data network and the supply to the driver boxes and light fittings. Every cable in the tunnel project was custom prefabricated in advance, equipped with the required connectors and labelled.

The aim of this is not only to save time but also to increase the success rate during installation, which is, at its core, once more a matter of saving time. Compared with the traditional connection method, the use of the QPD connectors achieved a time saving of 75% during installation, and up to 15% of the total installation time in the tunnel.

Thanks to the seamless cooperation between the various parties and the consistent application of plug & play principles, the relighting project for the Vierarmen Tunnel was completed in a smooth and efficient manner. A sustainable, technologically high-quality solution was implemented with minimal inconvenience. Good lighting in tunnels is an essential aspect in guaranteeing the convenience and safety of road users.