“Covid-19” – a common new term that the world has known since 2019. Many elevated sets of safe distancing measures have been widely adopted, with the movements of people being restricted in order to minimize the spread of the virus.

Singapore was not spared from the paramedic. The workforce in Singapore, where possible, had to work from home. Schools were closed, and the students moved to full home-based learning. Some businesses went into liquidation while others blossomed, particularly the online retailers.

Many of us changed the way we shop for our necessities or wants. For the heartlanders and neighborhood retailers, they brought their business online for contact-less transactions.

I am one of the strong supporters for online platforms, particularly those large e-marts , where it is like a one-stop solution shop where I can pick up all the necessary items in a single cart, instead of having to go around to different retailers to pick up one thing at a time in person. This saves me a lot of time, and petrol! Bringing more EFFICIENCY, which also means that I can use the same amount of time to get more work done. (I hope my boss sees this…)

This efficiency can be also be applied to the electronics design and manufacturing environment. One of the key fundamental elements to the success of a company, is managing the product costs. When you are taking longer than others to roll out a new design or when you’re not able to manage your material costs, it reduces the competitive edge that you may have. Time is of the essence.

Regardless if you are a Multi-National Corporations (MNC) or a Small Medium Enterprise (SME), the ability to turn around a new design and maintain a high production yield gives a higher efficiency and profitability level.

So, how can companies launch a new design in a shorter time and maintain a high production yield?

Let’s start from the basics.

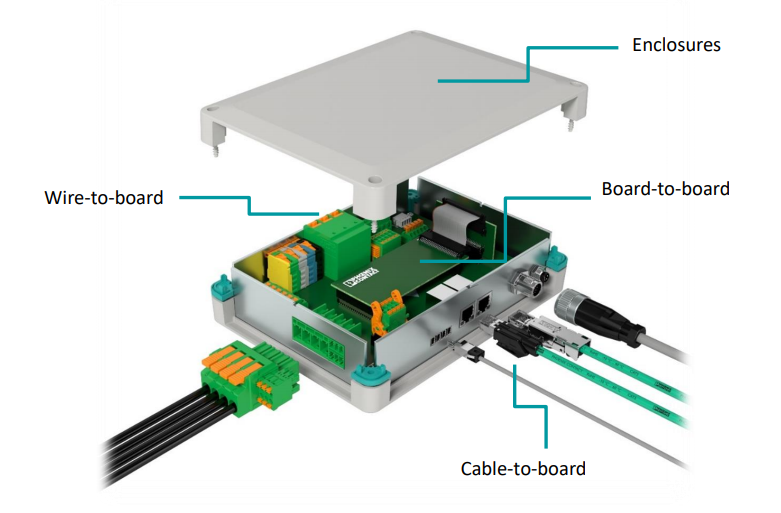

Every electronic device consists of at least 1 printed circuit board (PCB). The PCB would be encased to avoid exposing the components which would risk damage or accidental electric shock to the user. Apart from the casement, most devices would come with some form of connectors, such as power plugs, communication ports or signal I/Os.

During the design of the device, there are many considerations to make; from choosing the suitable connectors and components, the placement of the connector(s), the light emitting diode (LED), ventilation openings for heat dissipation and many more. Lastly the engineer needs to choose a suitable enclosure or get a customized one.

Sounds like shopping for a “new house”? Pretty much…

Most components would often come from various suppliers and manufacturers. The designer would also need to coordinate with different parties to realize the device.

Being the designer, you would want to reduce this coordination work as much as possible and put the time to better use.

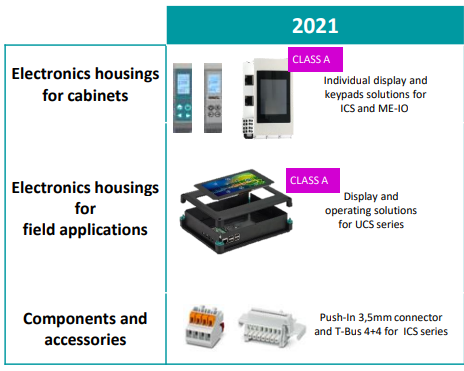

Phoenix Contact launched the first device enclosure portfolio back in the 1990s as a complementary product to the connector portfolio. Over the last decade, the portfolio has increased to not only include connectors, but other components such as heat sinks, keypads, light conductors and displays, making us a “One-Stop” solution supplier for devices.

Apart from the wide product availability, the business unit has also built up competency to be able to offer strong development consultancy and services, such as thermal simulations, printing and customized cut-outs for our customers.

After the design is finalized, the next important aspect would be the manufacturing process. In many manufacturing processes, the standard enclosure would be sent to a 3rd party for printing or opening of cut-outs for the LEDs or the field connectivity ports.

During this manufacturing process, it could result in damage of the electronic housing. This loss manifests itself as assembly scrap, which can result from breakage, poor quality, or nonconformance to specifications.

Meaning to say, you may place an order of 100 sets of the device and only 97 sets come back from the milling process that conforms to the finished product specifications, and this varies from time to time. Maybe you do get 100 sets in return, but at a higher cost.

Sounds too complicated?

Phoenix Contact is able to implement a customized enclosure solution coupled with connectors which will be delivered to you according to your specifications. We will also walk the journey with you providing complete support and cooperation throughout the new device development process until market release.

Reach out to the local Phoenix Contact sales team to find out how we can help you launch your new designs faster, with increase your yield of production with our enclosure and connector solution.

Now, we have the time for coffee together.