Hannover Messe is truly the centre of the global industrial community. In the month of April, the city of Hannover sees hundreds of thousands of visitors congregating. Leading solution providers and manufacturers often take this event as an opportunity to showcase their innovation in new applications and products. This year, we can still see, undoubtedly, the continuous hype around the initiative of Industry 4.0, and the unwavering push towards its adoption around the world.

Hannover Messe is truly the centre of the global industrial community. In the month of April, the city of Hannover sees hundreds of thousands of visitors congregating. Leading solution providers and manufacturers often take this event as an opportunity to showcase their innovation in new applications and products. This year, we can still see, undoubtedly, the continuous hype around the initiative of Industry 4.0, and the unwavering push towards its adoption around the world.

What exactly is Industry 4.0?

One might explain this as an industrial revolution where:

- A higher level of “Interconnectivity” is necessary with security implemented

- There is a need to create a digital twin through “Digitalization”, sharing digital information along the entire process

- There is smart system intelligence to allow “Decentralized Decision”

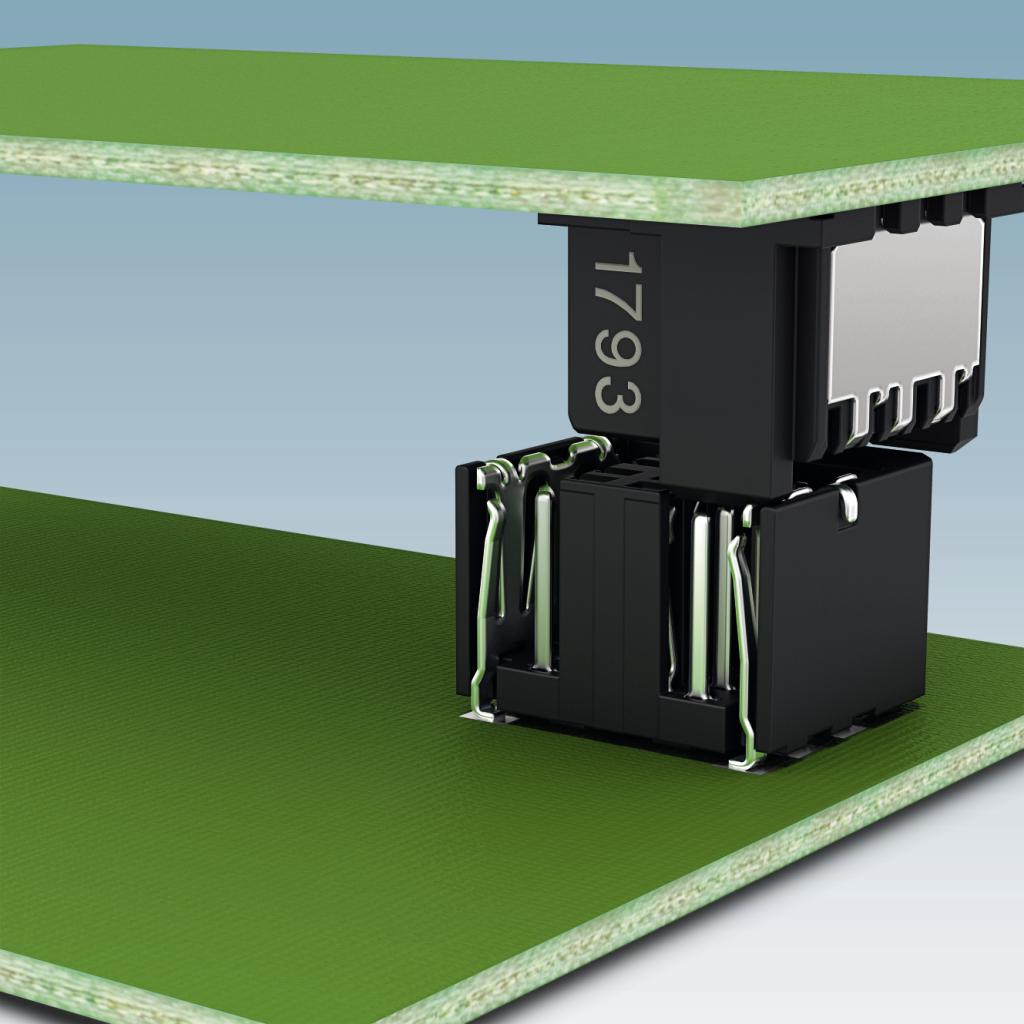

At Phoenix Contact, the COMPLETE Line System, for example, provides control cabinet manufacturers a holistic digitalized solution to plan and visualise their cabinet design and concept, before it goes into production. This will account for an optimized engineering process and improve productivity.

At Phoenix Contact, the COMPLETE Line System, for example, provides control cabinet manufacturers a holistic digitalized solution to plan and visualise their cabinet design and concept, before it goes into production. This will account for an optimized engineering process and improve productivity.

The highly celebrated PLCnext Technology Ecosystem takes automation into a whole new dimension. In collaboration with the ever increasing community of innovators, a digital marketplace has been launched, featuring purpose built-applications for automation, and software libraries to help accelerate PLC programming.

Taking advantage of the PLCnext hardware performance and open software system structure, PLCnext Technology will be a cornerstone for digitalized automation. The digital data can be upload to Phoenix Contact Proficloud, that provides the much needed visualisation (i.e.: augmented reality) across different stake holders of the organization.

Aside from the embrace of new technologies like IIoT, Cloud Computing, Augmented Reality which aid the transformation from the technological perspective, what about the enhancement of operational processes and the skill development the workforce within the organisation?

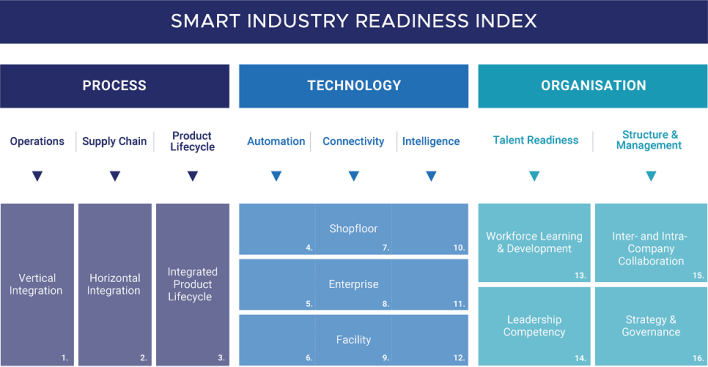

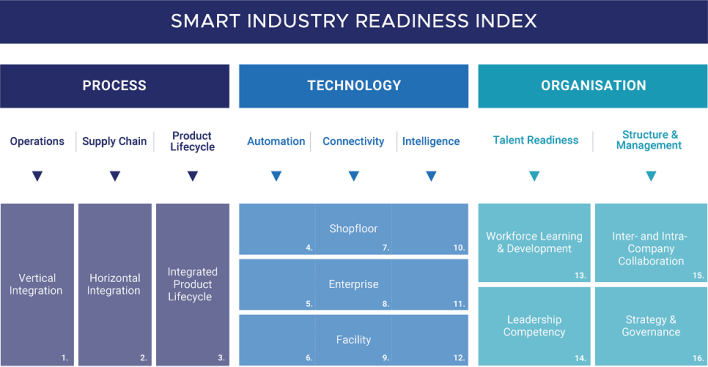

The Economic Development Board (EDB) of Singapore has launched the “Smart Industry Readiness Index (SIRI)” and its accompanying Assessment Matrix / Prioritisation Matrix, to provide companies a self-diagnostic tool to assess their readiness and architect roadmap towards this digital transformation.

Source: EDB Singapore

As seen from the above overview, SIRI provides the industry with a much needed guideline that identifies the 3 fundamental building blocks of Industry 4.0, namely: Technology, Process and Organisation.

These building blocks are then sub-categorised into 8 key pillars that represent the critical aspects which the company needs to focus on and subsequently into 16 different dimensions of assessment. The implementing company can then use these tools to evaluate their facility readiness, benchmarking their scores against others in the industry and finally plan and prioritise their implementation.

Interested to find out more? Get in touch with us at marketing@phoenixcontact.com.sg!