What is Industrial Automation: Part 1

Increasing competitiveness in the market over demands for high quality and consistent products remains a challenge for many organizations in the near future.

With protectionism and directives to ensure sustainable employment rates in countries such as the U.S, competitive pricing would also be the factor that is contributing to the industrial woes.

To address this challenge, a number of industries have considered alternative manufacturing techniques such as the usage of automated devices or IIOT (Industrial Internet of Things).

In Part 1 we shall explore what automation is all about, providing a reference for readers who are intending to switch over to the future.

Key Drivers for Automation:

- Demands for High Quality

- Consistent Products

- Affordable Pricing on Goods

Lessons from History

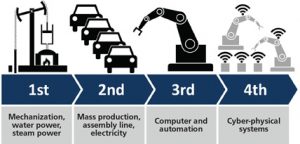

Consider the historical shift of the Industrial Revolution. Industrial 1.0 was all about water and steam powering companies to succeed against their competition.

Industrial 1.0 was all about water and steam powering companies to succeed against their competition.

In Industrial 2.0, Henry Ford’s Mass Production principles allowed Ford to produce affordable automobile at the fraction of the time and cost through assembly lines.

For Industrial 3.0, it focusses on robotics, enterprise resource planning, and lean production. Each and every process is accounted for to reduce wastage and unnecessary man-hours.

In today’s digital age, automation and big data would be the key aspect in determining business continuity for the foreseeable future. We call this age the Industrial 4.0 or the Fourth Industrial Revolution.

Key Pointers for the Growth of Industry 4.0:

- Historically, as economic issues arise, there will be creative ways to manage the issue.

- Industrialization has shifted to the next phase with every new technology introduced.

- While it has always been about speed and consistency, with automation, cost will be the major determining factor.

Birth of Industrial Automation

Industrial automation facilitates the increase in product quality, reliability, and production rate while reducing production and design cost by adopting new, innovative and integrated technologies and services.

What is Industrial Automation?

We are all familiar with mechanization – using machinery to aid human operators when performing a certain task.

Examples would be tools such as the modern excavator, tractors or forklift, to ease the workload and complete a task much faster.

The problem with mechanization is that it is highly depended on the human decision-making process to operate.

For automation, everything would be done via logical programming commands and sophisticated machinery, eliminating human error and achieving consistency.

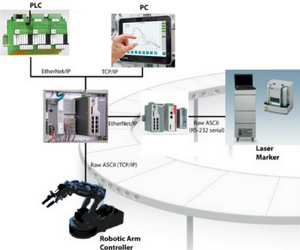

An example of an automated laser marking system controlled by the robotic arm but programmed by Humans via PC/PLC

In brief, industrial automation can be defined as “the use of technologies and automatic control devices that result in the automatic operation and control of industrial processes without significant human intervention, achieving superior performance than manual control”.

These automation devices include PLCs, PCs, PACs, etc. and technologies include various industrial communication systems.

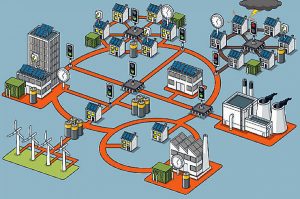

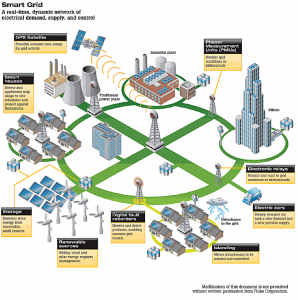

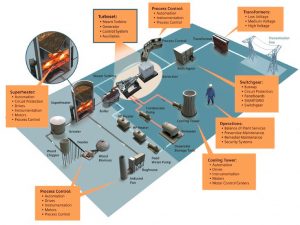

With the usage of automation, Big Data and also interconnectivity (IIOT), power plants can see significant results. (Credits: Siemens)

The above is an example of automation carried out in a power plant. It provides total integrated automation (TIA) by automating every section of the power plant with efficient control devices, field sensors and actuating devices.

In this example, PLCs are used as control devices while using Phoenix Contact’s PC Worx software to provide the graphical programming.

Stay tuned next week for Part 2 as we explore the hierarchy and levels of an automation system.

Otherwise, subscribe to our newsletter where you’ll get the latest and exclusive updates on our newest products for automation & IIOT.

Feel free to contact us at marketing@phoenixcontact.com.sg to find out more!