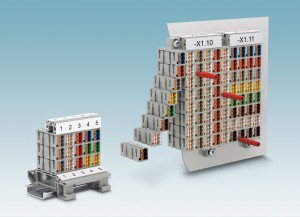

The new push-in PTMC marshalling patchboards from Phoenix Contact achieve up to 20 percent higher packing density with marshalling wiring in process technology, thanks to the modular concept and the compact design.

The individual marshalling patchboard elements snap into place easily and securely and can also be coded using eleven different colors. This ensures clearly arranged and fault-free wiring. The precise number of positions and the blocked form design, ideal for various applications, create a stable patchboard construction that is resistant to warping. The 2.3 mm test connections are easily accessible, next to the connection points, enabling convenient testing with standard testing accessories. The pre-assembled marshalling patchboards are available with four or six push-in connections per element in 32, 48 and 80-pos. designs. In terms of mounting type, there is a choice of direct, 19″ rack and DIN rail mounting.

The PTRV marshalling terminal system is the most compact on the market with a length of just 100 mm. It offers additions options for easy and clearly arranged marshalling wiring. Its key features include freely selectable colors, easily accessible test connections, and large-surface matrix marking.

The marshalling terminals and marshalling patchboards are designed for use in Ex i safety circuits up to 60 V and are available as blue versions.

The marshalling patchboards, which can be self-assembled, are configured and ordered with just a click of the mouse in the product area on the phoenixcontact.net/products website.