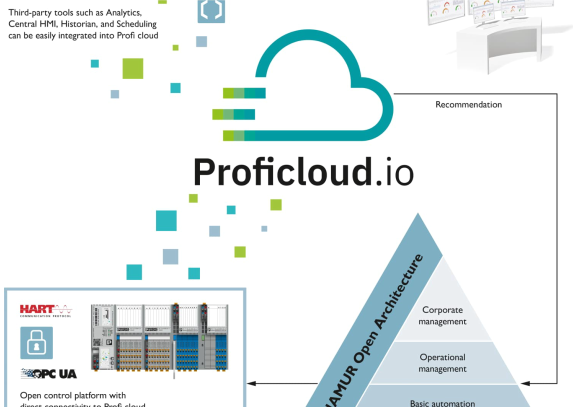

The energy revolution will significantly impact future electrical power generation and distribution since it is rapidly bringing about an All-Electric Society (AES).

Economical electrical energy produced from renewable resources, Is the primary energy source In the All-Electric Society, is which is almost inexhaustible. Comprehensive electrification, networking, and automation of all facets of the economy and infrastructure are necessary to make this future a reality.

This involves a more significant usage of non-linear or switched power producers and loads and an increasing decentralization of power generation using renewable energy sources for our power systems.

Restrict the harmonic loads and feed-ins in the transmission and distribution grid when they become more viable. This will include, among other things, an increase in measuring and safety equipment usage.

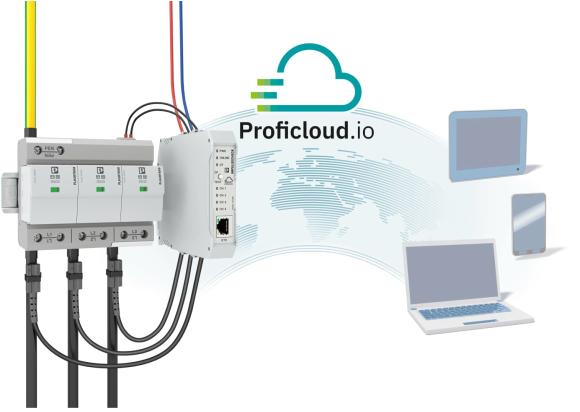

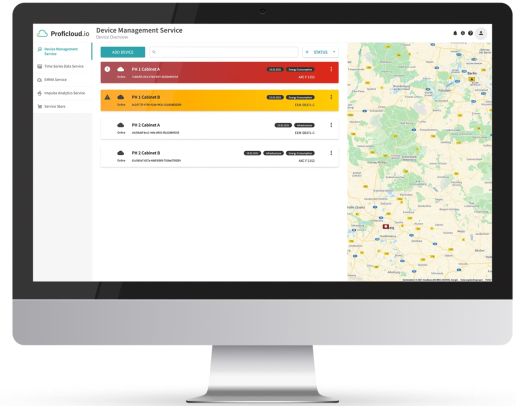

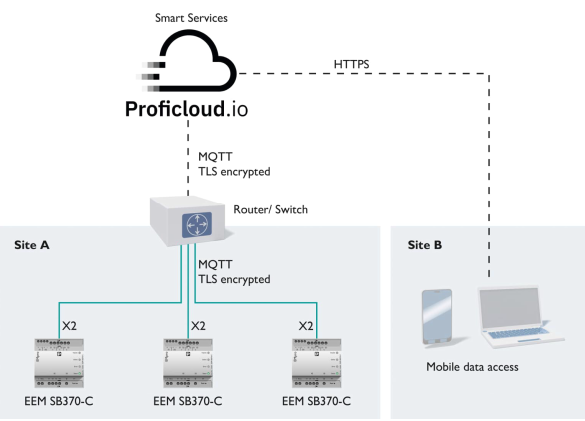

Creating more measurement points and the digital networking of signals from switchgear and substations in power distribution control systems need the conversion and modernization of current systems.

Here, measuring transducers convert high currents and voltages to quantifiable variables to acquire the measured values in the switchgear.

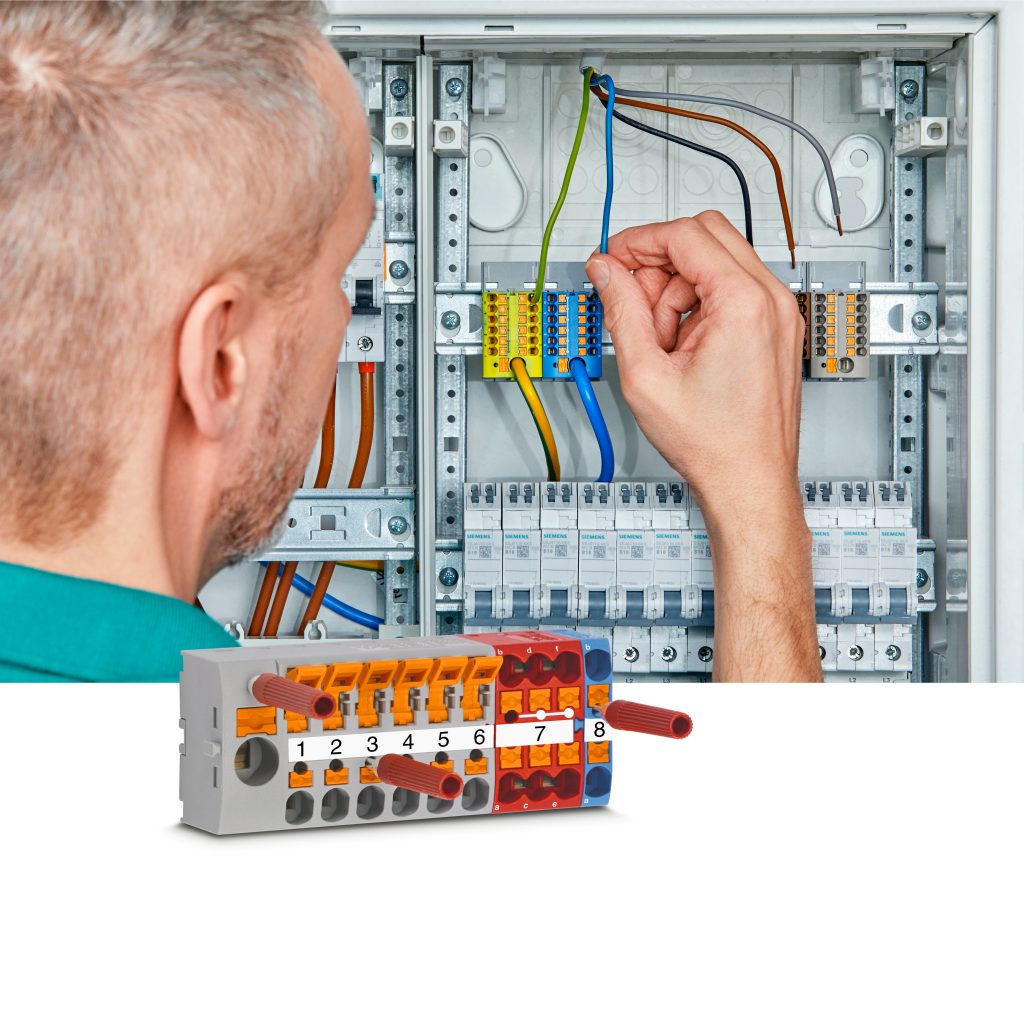

Terminal Blocks

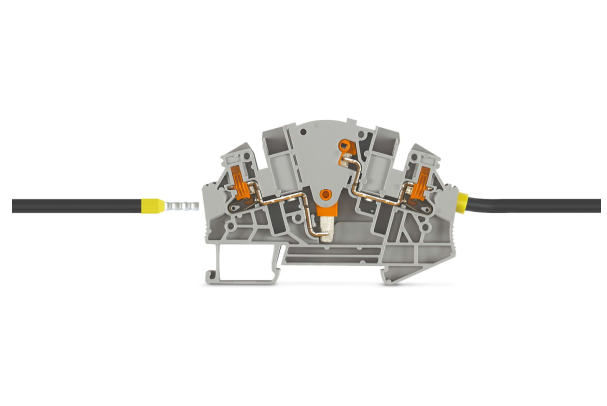

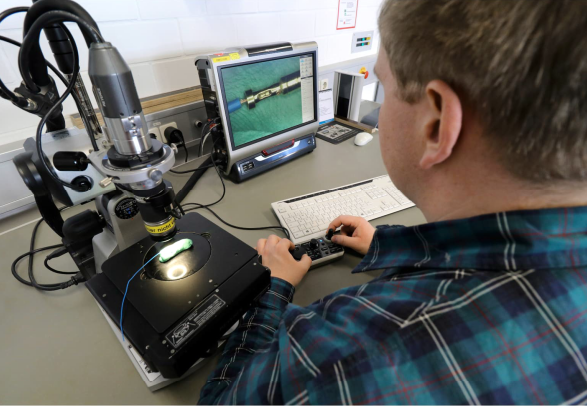

Test-disconnect terminal blocks serve as the link between higher-level evaluation units, such as metering or grid protection relays, and the measured-value acquisition performed by current and voltage transformers. As part of cyclic function testing, these disconnect terminal blocks allow for direct involvement in the program.

Here, safe handling is essential, made possible by the extensive touch protection in current test-disconnect terminal blocks. These terminal blocks offer a variety of test and switching accessories in addition to the disconnect element for secure, adaptable, and practical testing.

Older systems frequently have terminal blocks with switching accessories with basic or limited touch protection. Connect the testing sockets to the non-insulated test plugs to accomodate non separating switching parts. The widely used and well-tested screw connection method has included the conductor connection. Connect the testing sockets to the non-insulated test plugs to accomodate non separating switching parts.

Meanwhile, this area has shown to have enormous potential for future growth. Modern terminal strips contain extensive, standardized accessories like the CLIPLINE complete system and the possibility of conductor connection using quick and straightforward Push-in connection technology.

Quick and easy: Conductor connection with PTV

Push-in vertical

From a physical standpoint, screw connection terminal blocks have a long history and offer certain benefits over spring-cage terminal blocks. For instance, a screw connection allows several conductor connections at a single terminal point without requiring conductor pretreatment.

However, when it comes to upgrading systems, a spring-cage connection is becoming more and more popular.

One typical explanation for this is the frequent recommendation of routine inspections for screw connections to confirm the conductor’s torque-secure connection.

Phoenix Contact secures the screw connections by providing screw terminal blocks with built-in screw-locking mechanisms and eliminates the need for further checks

However, the aforementioned restrictions do not consider the specific items applied to screw connections.

The PTV terminal block, created by Phoenix Contact, is a unique replacement for screw connection terminal blocks.

PTV, short for “Push-in vertical,” is a connection method that uses the standard Push-in connection technology. The primary distinction is in the conductor routing, which is vertical and resembles a traditional screw connection as opposed to the front wiring of Push-in connection technology.

One notable benefit is that, unlike Push-in connection technology in the past, the terminal marking is clearly visible and not covered by the conductor routing. In addition, the lateral conductor connection offers advantages during the redesign if cables are permanently fixed in existing control cabinets and cannot be removed. Maintain additional cable length in reserve to alter the front wiring of the control cabinet. Utilize the cable length if the conductor routing changes.

PTV is the contemporary version of a screw connection; however, unlike a screw connection, it does not call for regular tightness checks.

Thus, the PTV test-disconnect terminal blocks combine the benefits of a spring-loaded conductor connection with those of a screw terminal block.

Compact design

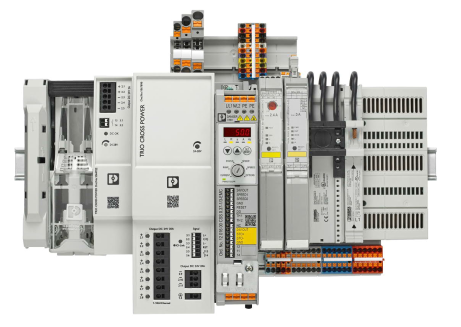

The control cabinet architecture is still crucial when replacing test-disconnect terminal blocks in existing systems since they cannot visibly outweigh the old ones in terms of length or breadth.

Due to their small dimensions, the new PTVME test-disconnect terminal blocks with vertical Push-in connections may be fitted in the location formerly held by the outdated screw connection terminal blocks.

The lateral conductor connection may still be made because of how small the terminal block is; even the clearly visible connection identifier is still placed above the conductor entrance.

Comprehensive accessories

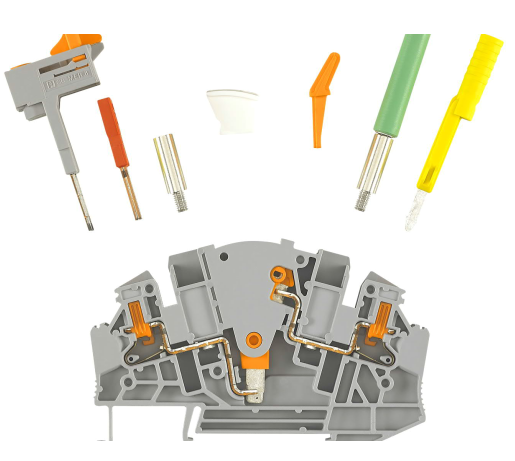

The screwless longitudinal disconnect element on the PTVME 6/S test-disconnect terminal blocks may be adjusted to the correct switch position with a screwdriver and locked into place.

Secure an auxiliary lever to manually control the disconnect element. The printed switch symbols indicate the switch locations. Utilize the switching locks on either side of the disconnect point to avoid unintentional activation.

On either side of the disconnect point are universal double-function shafts that let you utilize different bridge, test, and switching accessories.

When retrofitting systems, practical design and setup of terminal strips are crucial since they may quickly restore availability.

Push-in spring connection technology makes wiring quicker. The documentation and planning of terminal strips can take a significant amount of time. Clipx ENGINEER is a free planning and configuration tool by Phoenix Contact used from the CAE design stage to installation