Reaching into the box – simply explore new paths

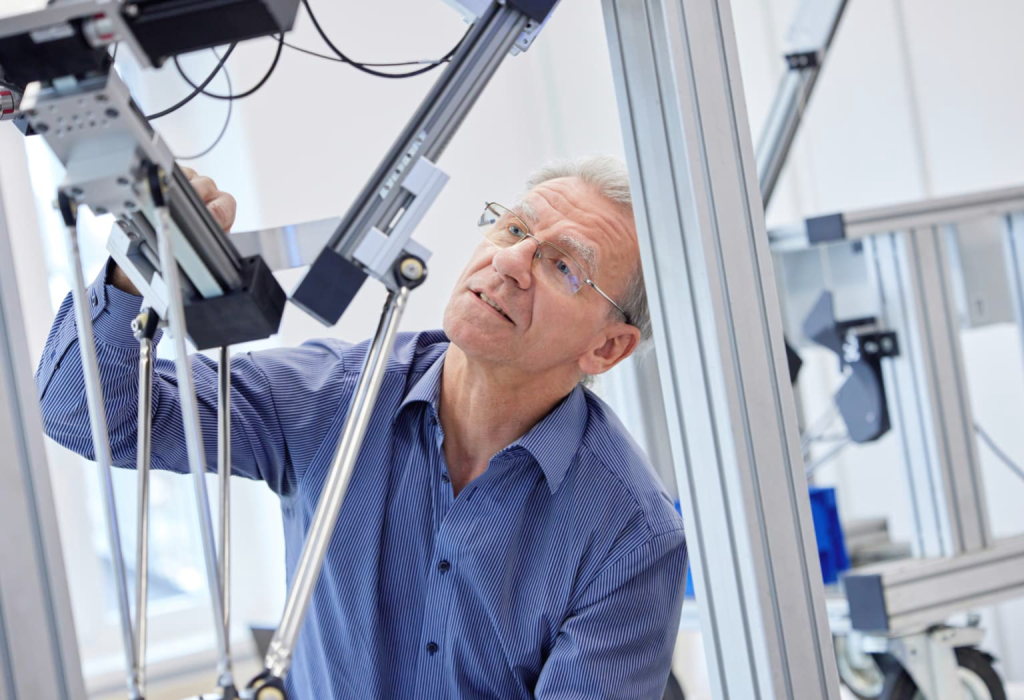

Berlin-based Sikora GmbH has developed a proprietary robot controller (SRS) to automate manual tasks in the automotive industry. The company, founded in 1999, has been instrumental in shaping laser welding and soldering in the automotive industry. The SRS allows for easy programming of robot movements, and the first series used was in an application that “reaches into the box.” The solution for positioning bulk goods does not involve high-precision robotics or special drives and components but uses simple physical methods like magnetism and gravity. The low-cost automation system is energy-saving, with many components coming from the company’s 3D printers. This approach balances individual system elements according to demand, requiring less drive power and less waste heat. Additionally, mechanical wear is optimized and service life is increased.

Transparent processes – fast learning – easy operation

Sikora systems offer a self-explanatory process sequence for operation and maintenance, simplifying maintenance work. They are designed for limited operation in emergencies and quick fault identification without software-intensive configuration. The system’s interfaces between the user and controller are easy to handle, with a haptic interface for easy operation. A small robot with axes moved manually and a two-line display completes the unit, which can be taught using a 3D printer. The system’s simplicity makes it a valuable solution for skilled workers.

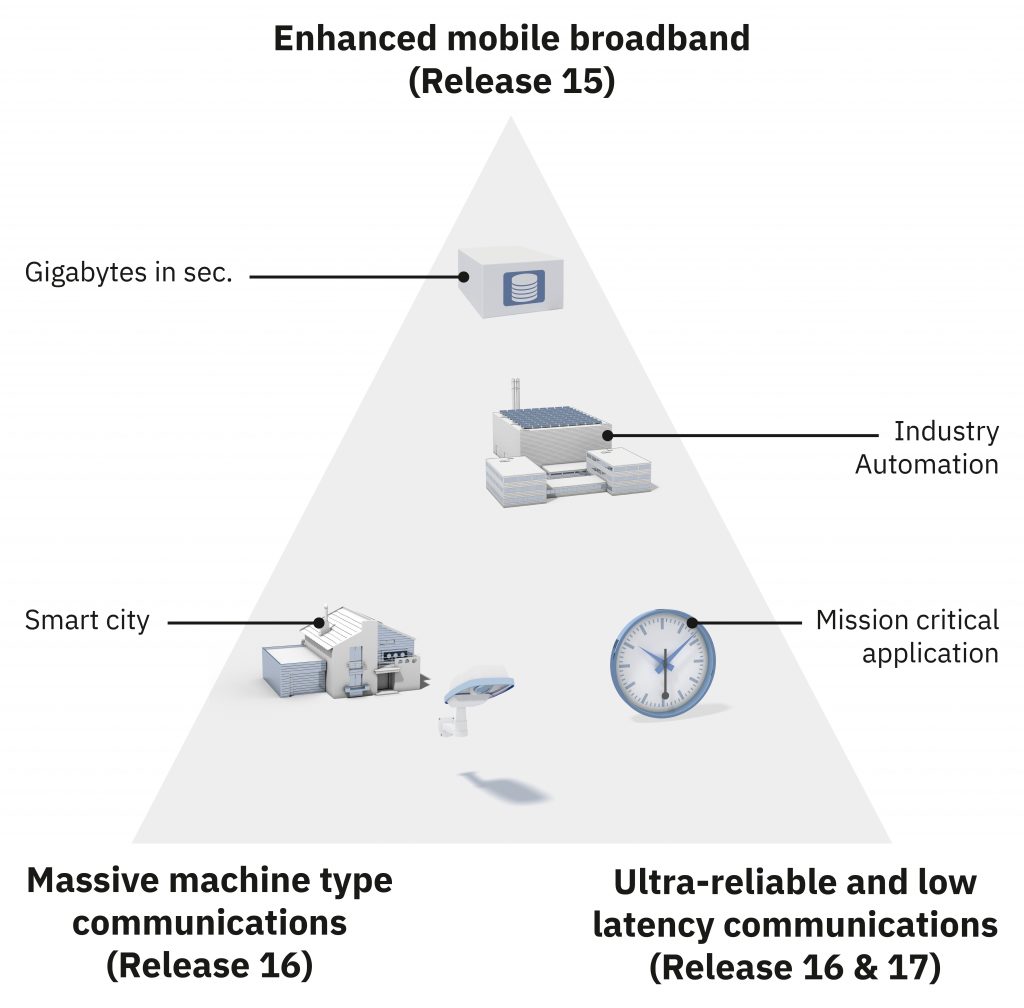

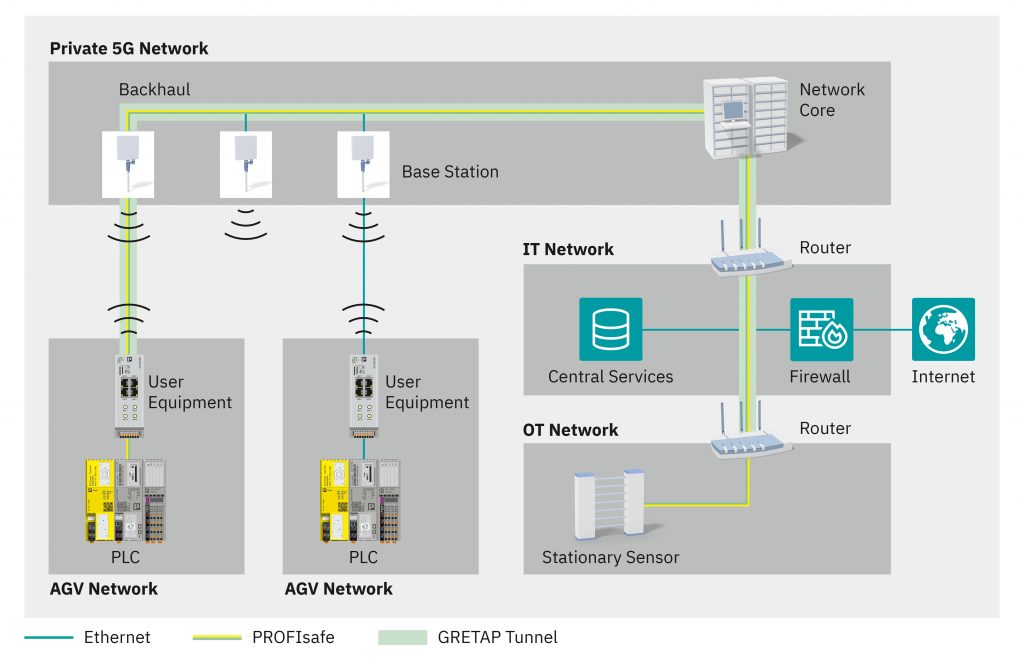

IT and OT on the same hardware

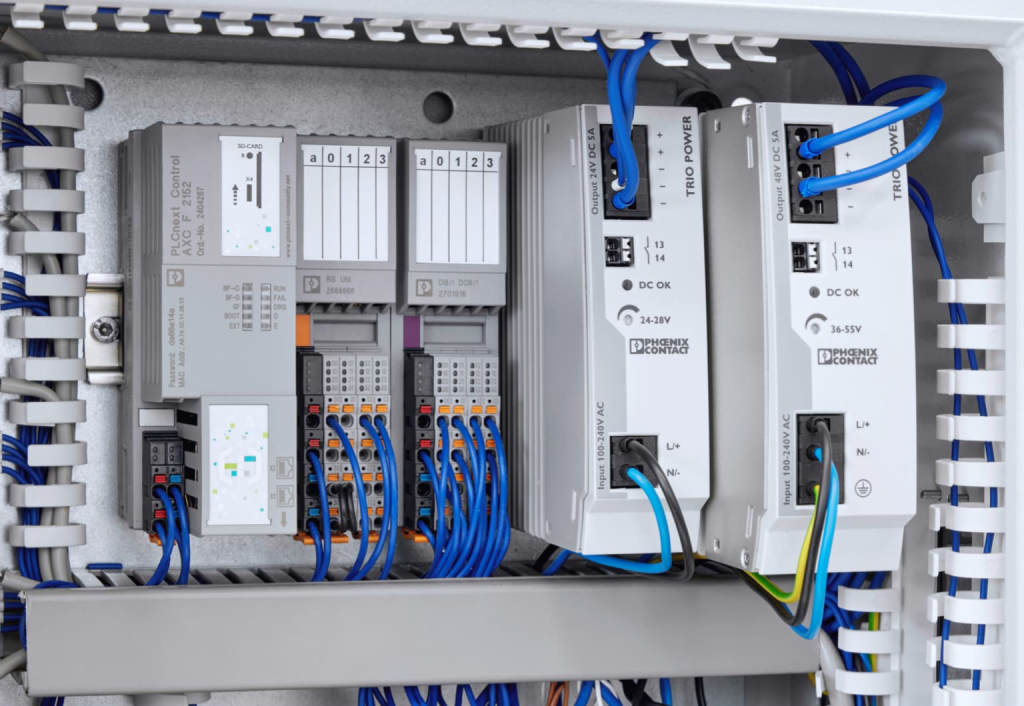

Sikora GmbH has developed a robot controller using C++ programming on Linux-based computers, but it requires appropriate hardware for use in harsh industrial environments. Ralf Sikora discovered PLCnext Technology from Phoenix Contact, which meets all industrial use requirements, including real-time capability and data consistency. The controllers enable the use of high-level language programs like C++, C#, and Python. PLCnext Technology also meets IT security requirements in automation, as per IEC 62443 standards. This allows for sensitive banking transactions on smartphones in public WLANs, reducing the risk of network attacks or unsecured data transmission.

Intuitive operation by the user

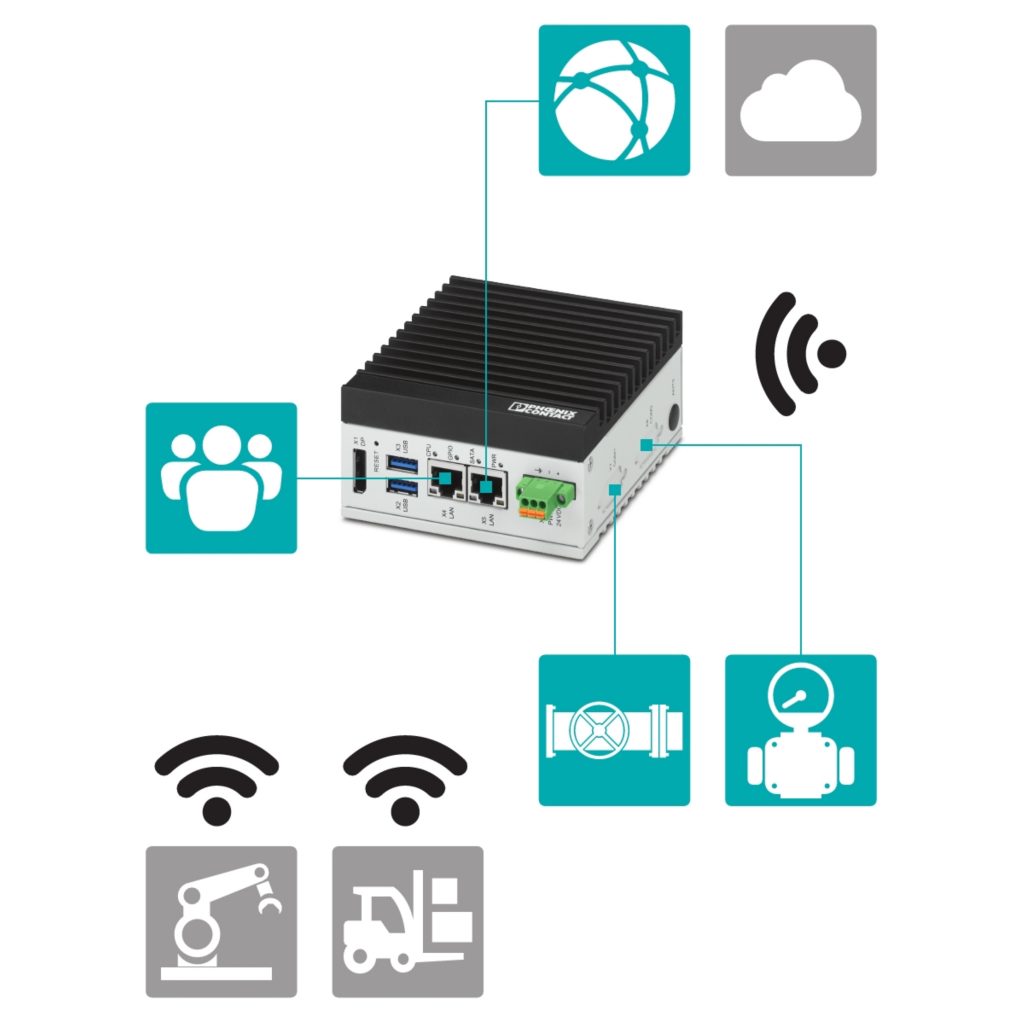

Sikora’s automation solution, PLCnext Technology, is easy to use and gaining popularity among IT sector users due to its open ecosystem, which supports high-level language applications, database connections, cloud communication, artificial intelligence, and apps.

Industrial tasks have evolved from technical feasibility to user preference. Smartphones, for example, are intuitive and easy to use, but complex technology is still present. Automation systems must be quick and trouble-free for operators and maintenance personnel, increasing application availability. Open-source IT solutions make app interfaces on smartphones easier to use.

Learn more about PLCnext Technology.