Phoenix Contact tested various cable types in building automation to determine if existing cables can be reused for Single Pair Ethernet (SPE). The investigation compared the technically relevant sizes of the cables with the limit values of ISO/IEC 11801-3, IEEE 802.3cg, and IEEE 802.3da. In addition, the quality of signal transmission over different cable lengths was examined using parameters to assess signal integrity.

Determination of the cable types

The KNX protocol is widely used in building automation in Europe, particularly in Germany. J Y(ST)Y 2x2x0.8 type cables are used for bus signals, power installations, and process data processing. The YV 2×0.8/1.4 jumper wire, also known as a bell wire, is used for point-to-point connections. These cables were examined for their reuse in SPE connections.

Selection of suitable measured variables and measurement methods

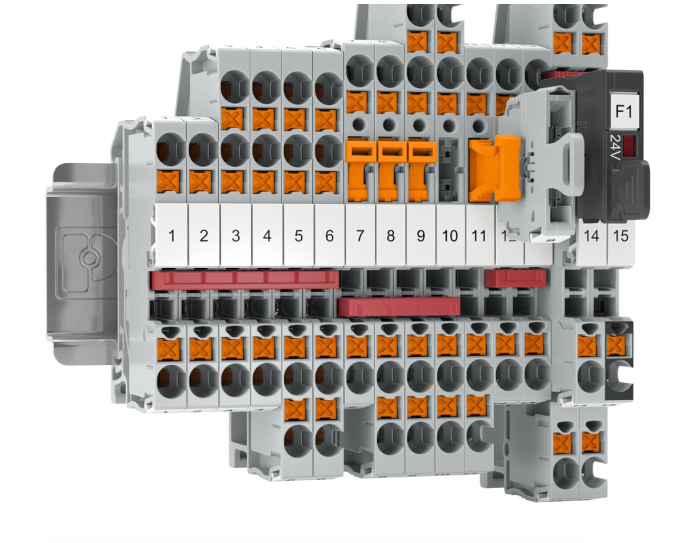

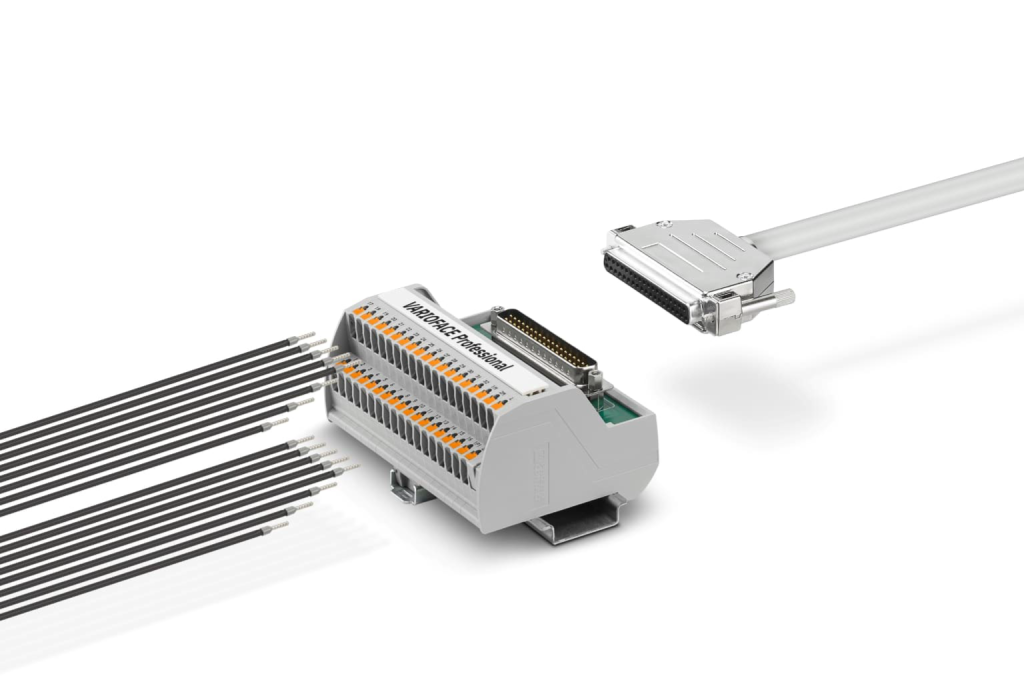

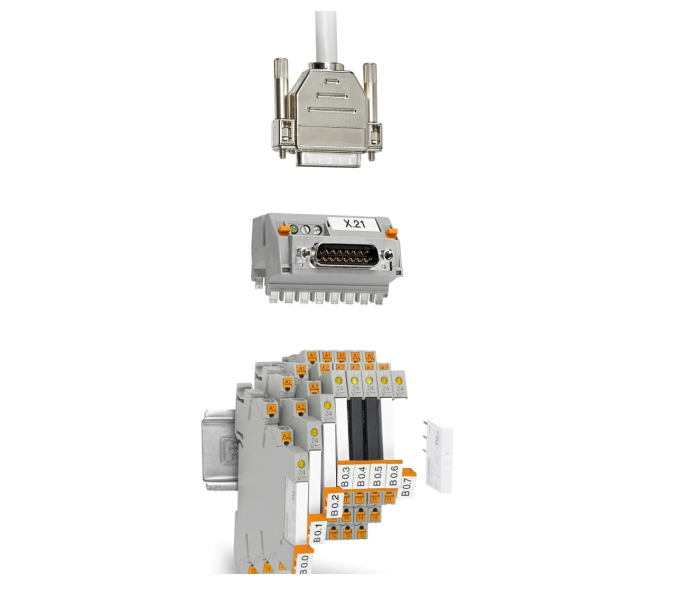

The Fluke DSX 8000 field tester was used for cabling measurements, qualifying Ethernet cabling, and testing patch cables. In contrast, comparative measurements were conducted using the ZNBT vector network analyzer. Cables with good transmission properties meet limit values for RL, IL, and TCL and require constant independence of the cable. Phoenix Contact SPE connector was used for easy connection.

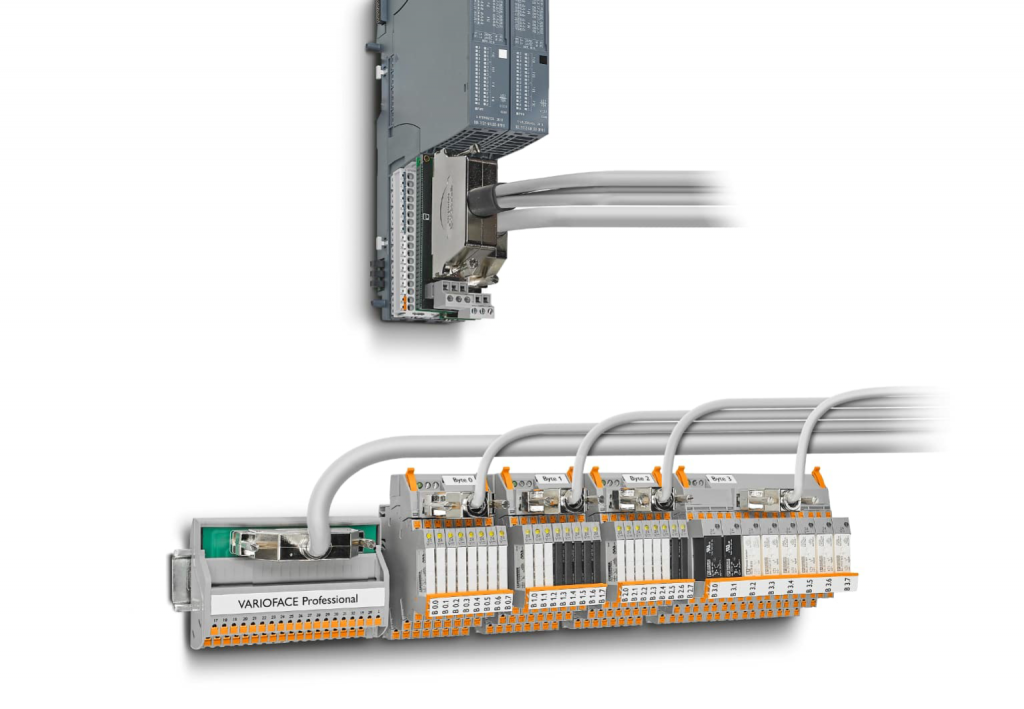

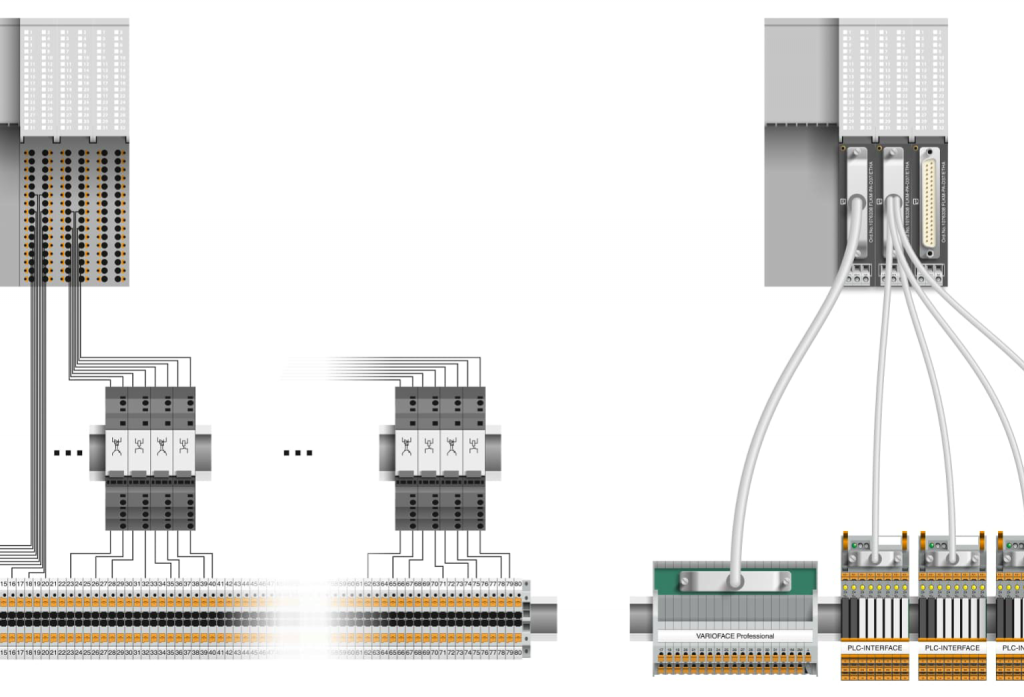

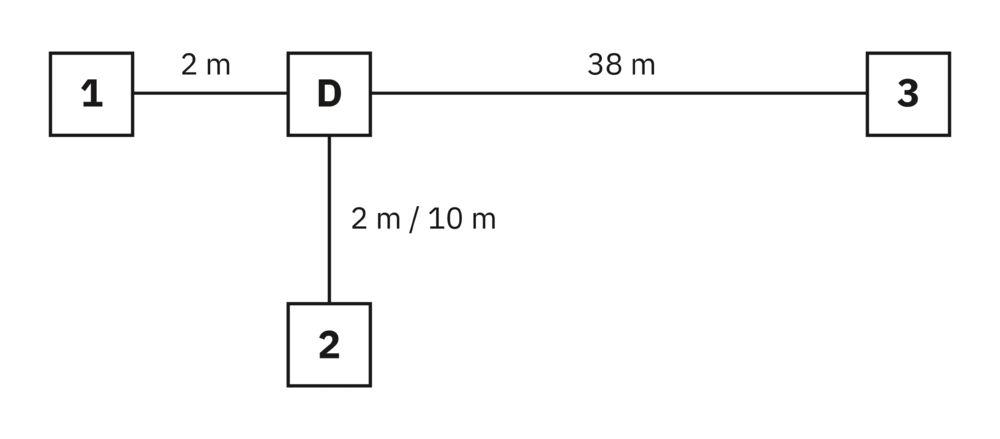

Investigation of realistic cabling structures

Moreover, existing bus line infrastructures can have unknown topologies, making it difficult to dismantle the installed cables. The transmission path has branch lines of varying lengths. A T-shaped line arrangement with master cables and branch lines was examined. The results showed that short cable lengths and non-terminated cable ends were problematic. Long cables were found suitable for SPE transmission.

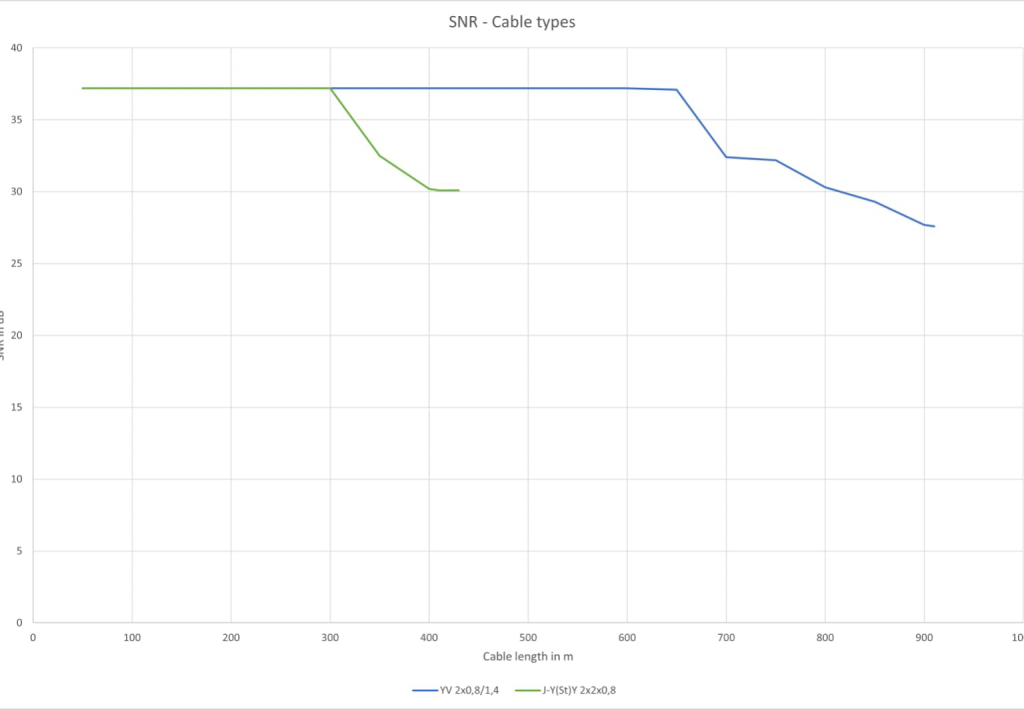

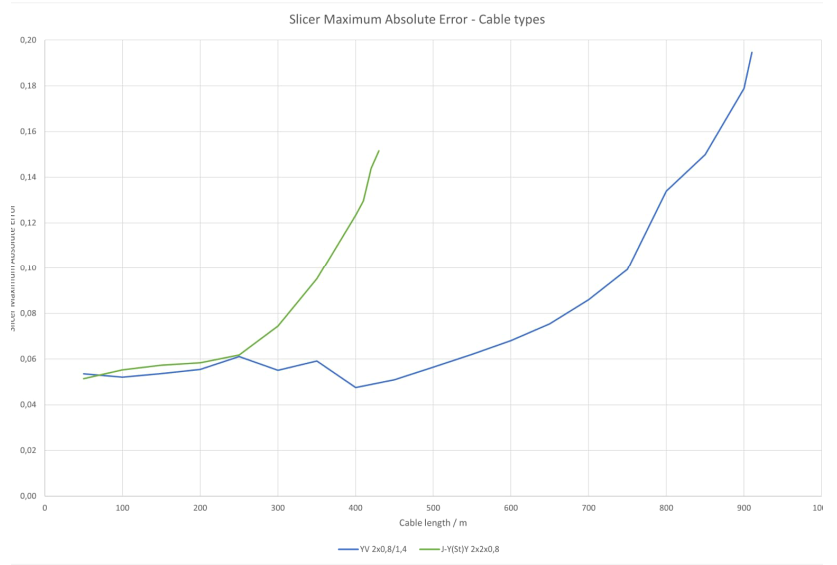

Signal-based investigations

The KNX bus line and jumper wire’s Signal-to-Noise Ratio (SNR) and Slicer Maximum Absolute Error were measured using two evaluation boards. The KNX bus line achieved a maximum range of 420 m with a minimum SNR of 30.1 dB and a Slicer Maximum Absolute Error of 0.15, while the jumper wire reached a maximum range of 910 m.

Learn more about Single Pair Ethernet.