Asynchronous motors are supplied via over-dimensioned frequency converters (FCs). Since a speed starter’s noteworthy advantages include quick installation and starting, it is perfect for simple programs with few functionality.

Industrial plants contain a large number of electric motors. The majority of motors carry out straightforward functions, such as moving things or liquids from one location to another or carrying out the necessary processes.

Logistics centers, machines, and systems perform these tasks. A motor is operated in a variety of ways. Nowadays, frequency converters are employed in the majority of applications, particularly when soft starts or varied speeds are necessary.

Frequency converters are intricate machines that perform several tasks but are frequently oversized. This is due to the fact that their most prevalent applications at the moment usually include straightforward activities that simply demand for two fixed speeds and/or a ramp function with a gentle start and soft stop of the motor.

Safe shutdown up to SIL 3 and PLE

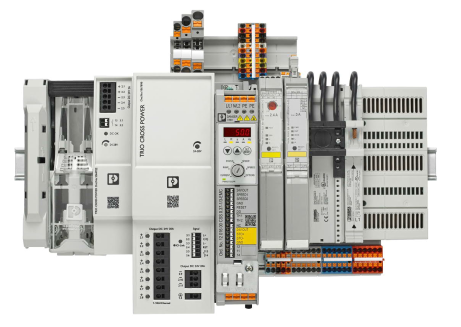

A device class between motor starters and frequency converters is provided by the new speed starter from the Contactron product family. The small solution provides all required features in a single housing and impresses with its simple operation:

- Direct start of asynchronous motors

- Reversing start

- Full motor protection

- Different speed settings

- Soft start and soft stop of the motor

- Safe stop with Safe Torque Off

The device has several benefits for the user, but its built-in Safe Torque Off (STO) capability allows for a safe shutdown up to safety levels SIL 3, PL e, and Cat 4. There is a substantial space savings in the control cabinet due to the small housing dimensions, which have an overall width of only 35 millimeters.

Easy wiring and an intuitive operation concept ensure quick installation and startup. As a consequence, it is possible to adopt a cost-effective solution using the speed starter from the Contactron product family, which has all the essential features for varying speeds and soft start.

In the most common uses, an emergency stop switch must be able to securely stop rotating and moving parts, for instance, in the event of a jam or an emergency. Use the Contractron series’ quick starter to design a redundant system and prevent malfunction, hence, ensuring safety.

Therefore, a second contactor is not necessary for a safe motor shutdown. On the controller side, use the STO+ and STO- connectors to accomplish a two-channel shutdown . With only a short installation area, the Contractron fast starter achieves safety classifications SIL 3, PL e, and Cat. 4.

Quick startup in less than a minute

Machine manufacturer can offer a more competitive solution and speedup the application installation by using Phoenix Contact’s speed starters.

To start the motor and apply a control signal to an adjustable fixed speed, you must wire the load input and output. The motor can then start operating right away. It must be possible to customize the parameters for the appropriate application, of course. The user-friendly operating idea, which consists of a display, five LEDs, two up and down buttons, a set/reset button, and a rotary switch, accomplishes this.

Setting the motor’s nominal current is the first step in protecting it against overload. As a result, it is no longer essential to install an additional motor protection relay. Set the rotary switch to the “Current” position and input the desired value by using the up and down buttons. Verify the value by pushing the set/reset button. When a value is changed, it immediately begins to flash in the display. The value is always visible after saving. It is also simple to adjust the ramp time, or the amount of time the motor takes to reach the desired speed.

To achieve this, the user simply moves the rotary switch to the “Ramp” position, inputs the new value using the up or down button as previously mentioned, and saves it by pushing the set/reset button.

Different versions for different requirements

Set the rotary switch to “Status” to view electrical values such as frequency, current, voltage, temperature, etc. Use the same method to adjust the speed.

Set the speed to the “Speed1” position and select the correct frequency value by using the up and down buttons. Verify your selection by pushing the set/reset button.

The LEDs flash in the “R” or “L” direction of rotation, which is also selectable with the up or down button and remembered by pressing the set/reset button. Repeat this procedure to facilitate a second speed:

- Move the rotary switch to the “Speed2” position.

- Specify the value using the up or down button.

- Press the set/reset button to confirm.

If desired, the user can make additional settings by turning the rotary switch to the “Options” position.

For single-phase and three-phase load input, the speed starters of the Contactron series offers performance classes ranging from 0.25 to 1.5 kilowatts, with or without an integrated EMC filter. The devices with filters built in come with a plug-in, changeable fan, whereas the ones without filters only have a heatsink.

In conclusion, fast starters are a convenient option appropriate for a variety of uses. Users gain from a device class positioned between motor starters and frequency converters under the tagline “Connect, set, start.”