Phoenix Contact achieved sales of EUR 2.38 billion in 2018 with sales growth of 8%. At the same time, the number of employees increased to 17,400 worldwide.

“From a global perspective, we had very good growth figures in the markets, but had to accept negative currency effects,” says CEO Frank Stührenberg.” In Germany, still our most important market for Phoenix Contact, we again achieved a very good result with 7%. There was double-digit growth in all regions of the world”.

The company invested €207 million in IT infrastructure, machinery and equipment as well as buildings. An amount in excess of 200 million euros will again flow into investments this year. In China, for example, Nanjing, the headquarters of our Chinese subsidiary, will expand its production and logistics facilities to a total of 23,000 m². The location will be completely built according to Industry 4.0 standard. The site in France will invest 15 million euros in logistics and office space by 2020. The logistics in Harrisburg, USA, will be expanded by 7,700 m². A new building for printed circuit board connection technology with 10,300 m² is currently being built in Blomberg. Development units, laboratories and product management offices in the immediate vicinity of the production building will find their home here.

In the current year 2019, a budget of 7% of sales for research and development will primarily serve product technology for digital transformation as well as solutions for the future markets of energy, mobility and infrastructure.

At the Hannover Messe, which began on April 1, Phoenix Contact, once again, was the third largest exhibitor presenting its solutions for the digital transformation. With a total of 2,500 m², the company was present at 11 trade fair stands.

Learn more about our highlights and focal points at Hannover Messe.

Click here to know more about who we are and what we do.

Ideally suited for simple, space-saving potential distribution: the PTCB single-channel electronic circuit breaker can be bridged to the CLIPLINE complete terminal block system, and offers a setting range from 1 to 8 amperes with an exceptionally narrow overall width.

Ideally suited for simple, space-saving potential distribution: the PTCB single-channel electronic circuit breaker can be bridged to the CLIPLINE complete terminal block system, and offers a setting range from 1 to 8 amperes with an exceptionally narrow overall width.

Multi-level terminal blocks for building installation save space

Multi-level terminal blocks for building installation save space Suitable for everyone

Suitable for everyone High speed, future proof data transmission

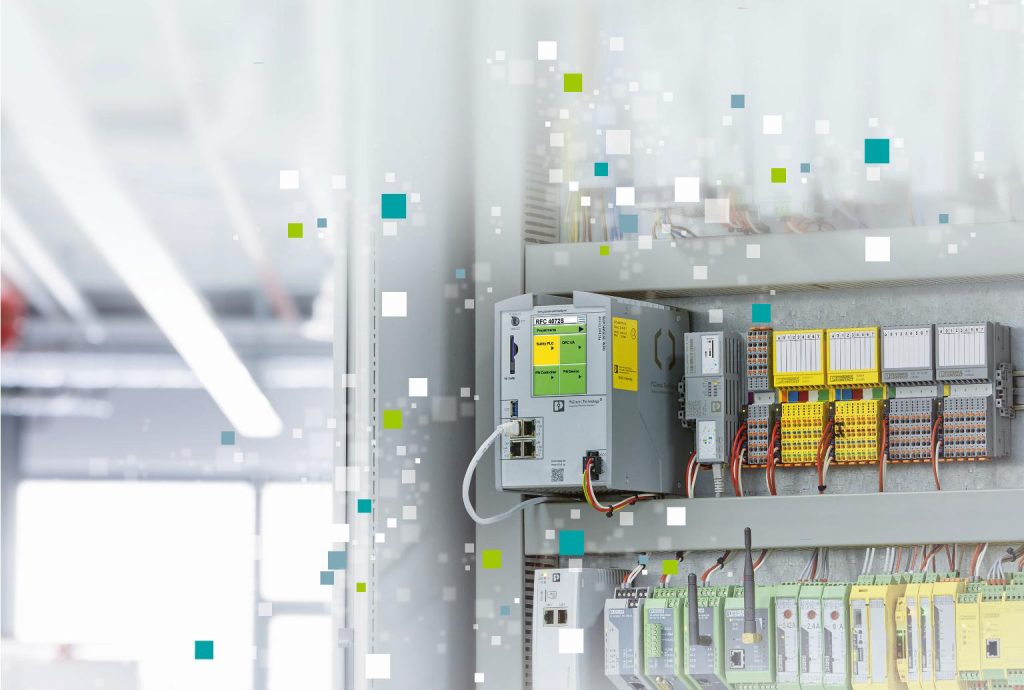

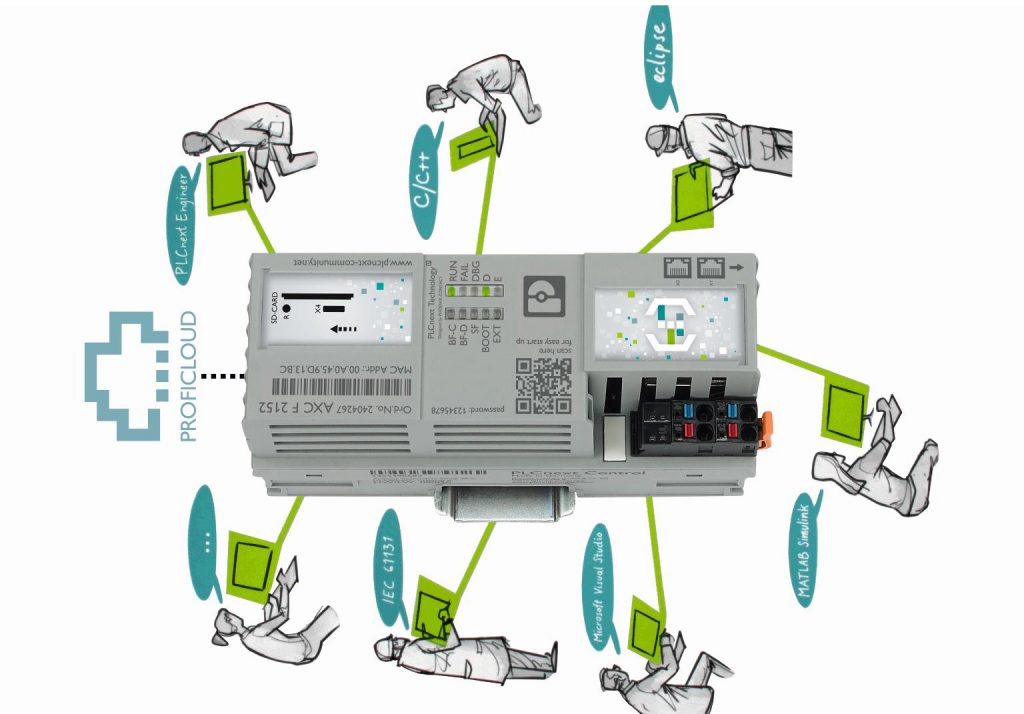

High speed, future proof data transmission PLCnext Technology – The platform for limitless automation

PLCnext Technology – The platform for limitless automation Efficient laser marker

Efficient laser marker The narrowest surge protection for I/Os and controllers

The narrowest surge protection for I/Os and controllers QUINT DC UPS for industrial networks

QUINT DC UPS for industrial networks Compact high-performance power supply

Compact high-performance power supply