Control cabinet building can benefit from optimization through digitalization, lean management, and agility approaches. However, manual activities still dominate production, making automation difficult. Electrically skilled personnel are essential for wiring and adaptability, as they understand equipment requirements and can react to unforeseen challenges that cannot be mapped in a highly automated process.

The skills shortage exacerbates the problem

Traditional control cabinet building relies on well-trained electrically skilled persons for long-term success, and automation is limited. in addition, time is pressing to integrate the remaining electrically skilled persons into relevant production processes. Moreover, untapped potential in information flows and digital support exists, especially for small and medium-sized companies.

Weaken your weaknesses and strengthen your strengths

The saying “Focusing on strengthening your positive qualities and skills while trying to overcome your weaknesses” fits well the digitalizing of company processes. To implement this strategy, identify and categorize areas of the company based on their influence on the company’s success. These areas are typically technical and represent the company’s competitive advantage. The support categories include non-technical areas necessary for core competencies tasks, while organization categories include non-specific areas like HR departments. Introducing market-standard software can help digitalize these areas, addressing weaknesses. However, standard commercial software may leads to loss of unique selling points, impacting the company’s competitive advantage. The digitalization plan should consider practical requirements, employee needs, and company goals.

The role of detailed analysis

A thorough analysis of information flow is the first step towards optimizing. Understanding all work steps is essential to identify optimization potential. Digitalized worker assistance systems can help by directly supporting work steps with necessary data. However, ad-hoc integration and digitalization without prior analysis can lead to unnecessary data addition, making the problem worse. However, as humans, we are not good at processing large amounts of data quickly. More data is generally required for automation, but in manual production, it can lead to waste and inefficiency. The challenge lies in sorting and filtering existing data to make it more accessible to employees in a targeted manner.

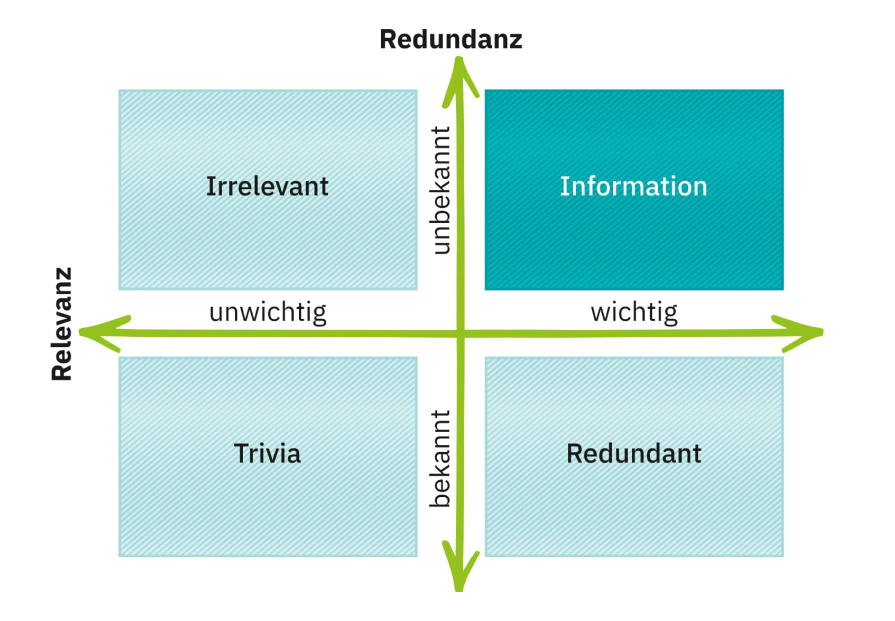

Data is not always information

In digitalization projects involving people, it’s crucial to differentiate between data and information. The term data is used here as a generic term, regardless of its use, and information is the part of the data that is necessary or beneficial for the process. The implementation only considers data classified in the Information field, with redundant data included if necessary. Uniform implementation in the form of just a document, as is the case in production supported by paper documentation, is therefore not the optimal solution, as it can lead to the optimization of specialist processes. Paperless production is a welcome side effect of digitally supported optimization.

Learn more about control cabinet building.