Solving the challenges of the future with swarm intelligence

The significance of interdisciplinary collaboration between a company’s internal and external experts is increasingly recognized as essential for solving complex tasks efficiently. The PLCnext Community from Phoenix Contact exemplifies this approach in the open PLCnext Technology ecosystem. Just as collaboration is crucial in building a house with various specialists, it’s similarly vital in today’s digitized work environment across industries. Challenges like skilled worker shortages highlight the importance of cooperation among employees. In the automation industry, developers and engineers face intricate technological problems, often requiring collaborative efforts. This is especially valuable in new business areas where a company lacks experience. Online forums and digital communities facilitate information exchange and experience sharing among developers.

Reducing travel and office costs

In the 1970s, digital exchange methods existed even before public Internet access. In 1979, students from Duke University created Usenet, a virtual platform for cross-border forum-based collaboration, using the UUCP protocol. Organizational psychologist Prof. Dr. Guido Hertel from the University of Münster highlights the benefits of internet-based collaboration, such as international teams working across time zones and involving experts with minimal costs. Virtual collaboration reduces travel and office expenses, and the rise of online meetings due to COVID-19 has made web-based video conferences normal. With increasing home office adoption, network-based collaboration tools like Slack, Wire, and Rocket are gaining importance.

Increasing sales growth

A notable trend is the increasing reliance on cross-functional collaboration by large, globally operating companies as part of their digital transformation. A 2020 Accenture study found that companies using this approach achieved more than double the sales growth compared to those that didn’t. Effective collaboration across functions reduces costs and leads to measurable returns. Companies benefit even more in innovation and speed when they involve external partners in their development processes, alongside internal efforts. This shift turns a closed company system into an open ecosystem, tapping into external knowledge and creativity. Deloitte highlights this openness as a critical competitive advantage in the fast-paced digital economy.

Platform for subject-oriented exchange

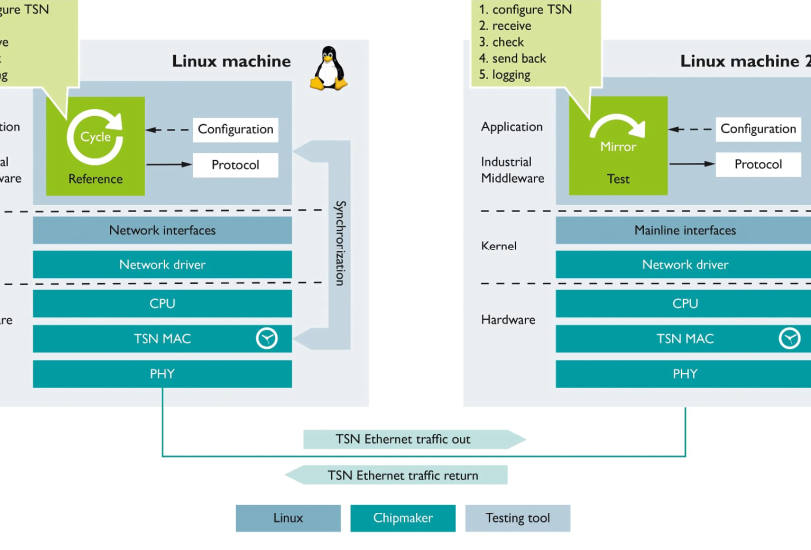

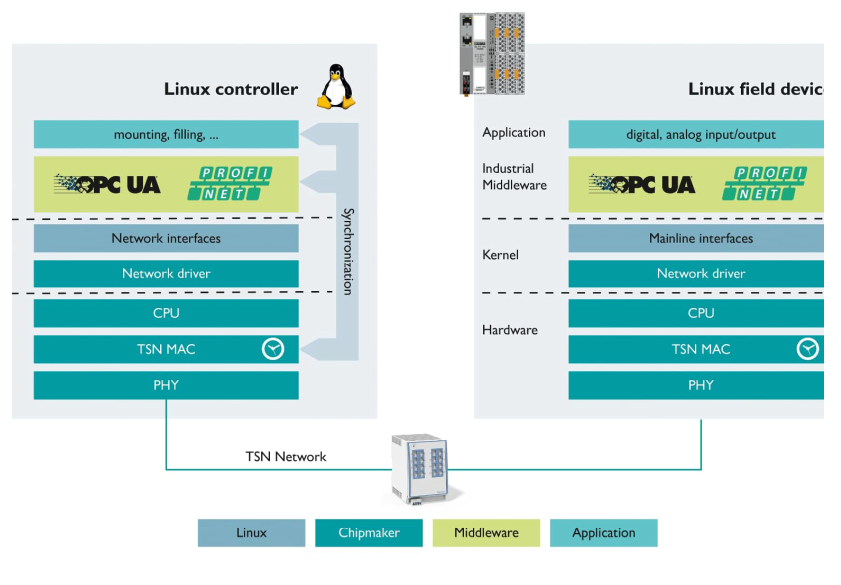

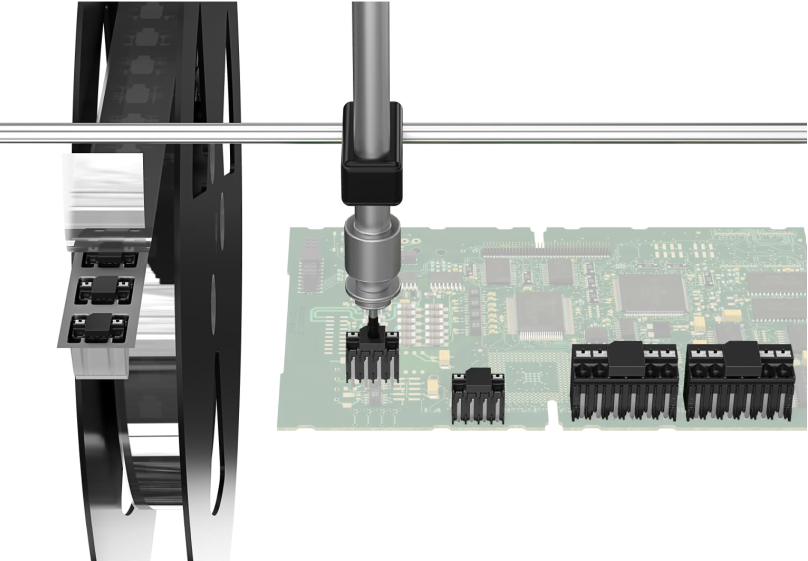

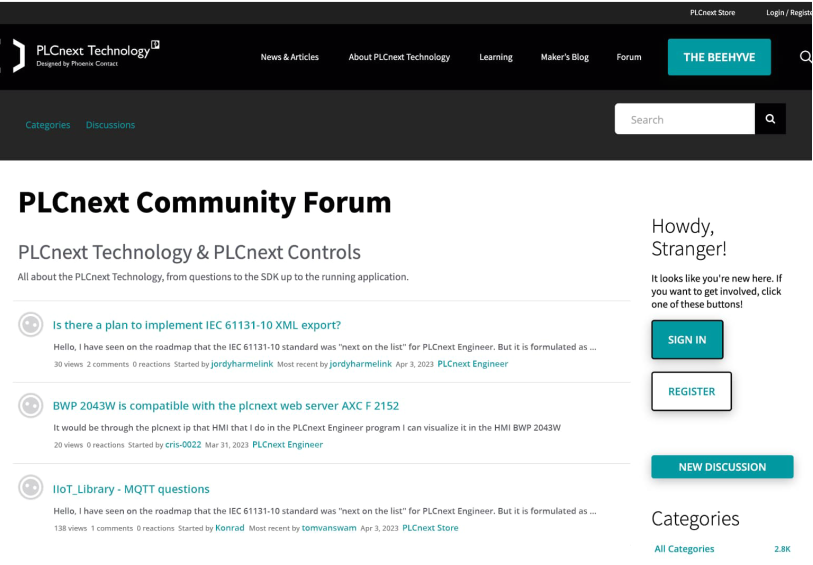

The terms “collective intelligence” and “group/swarm intelligence” refer to intelligent decision-making through collaboration among individuals, often observed in decentralized systems with non-hierarchical cultures. Phoenix Contact exemplifies this with PLCnext Technology in industrial automation. It reimagines automation for digital transformation, using a Linux-based real-time-capable PLCnext Runtime System that’s open to various protocols and tools. The PLCnext Store, an online marketplace, enables exchanging reusable blocks and apps, fostering collaboration. The PLCnext Community supports this ecosystem, aiding users in using the hardware and software, sharing experiences, and enabling project success. Notable examples include students using community resources to measure social distances and companies benefiting from shared insights for automation app development.

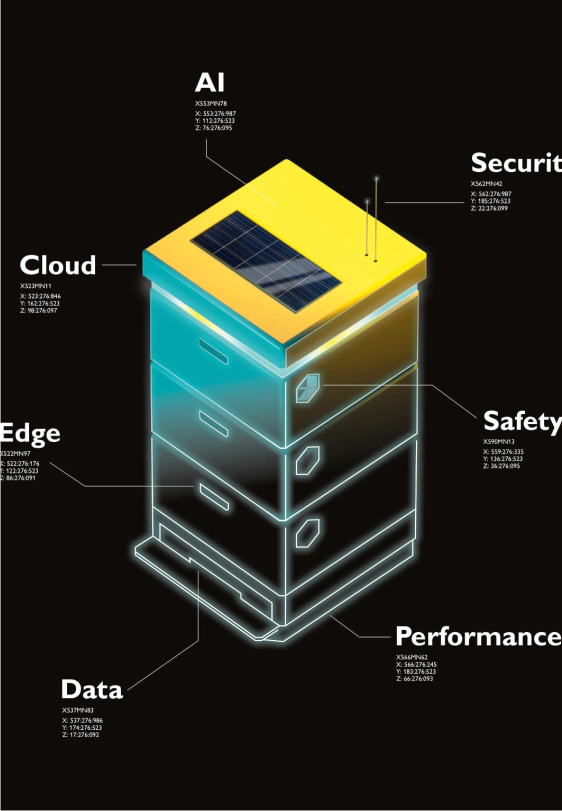

Project for protecting bees

The PLCnext community is working on a sustainable project with the “Beehyve” campaign to protect bees using advanced automation. ChatGPT, an AI-based system, represents a new form of collaborative technology. Phoenix Contact has been working in collaboration with its customers, the science community, and society ever since it was founded 100 years ago.

Find out more on our website.