Optimized processes and coordinated system solutions for greater efficiency in wire processing

Control cabinet builders face international competition, skilled worker shortages, and increasing labor and material costs. In-house production and cost structure are increasingly under spotlight. The process chain in control cabinet building offers potential for efficiency gains in engineering and production through the use of optimally coordinated systems.

Identifying time-consuming process steps

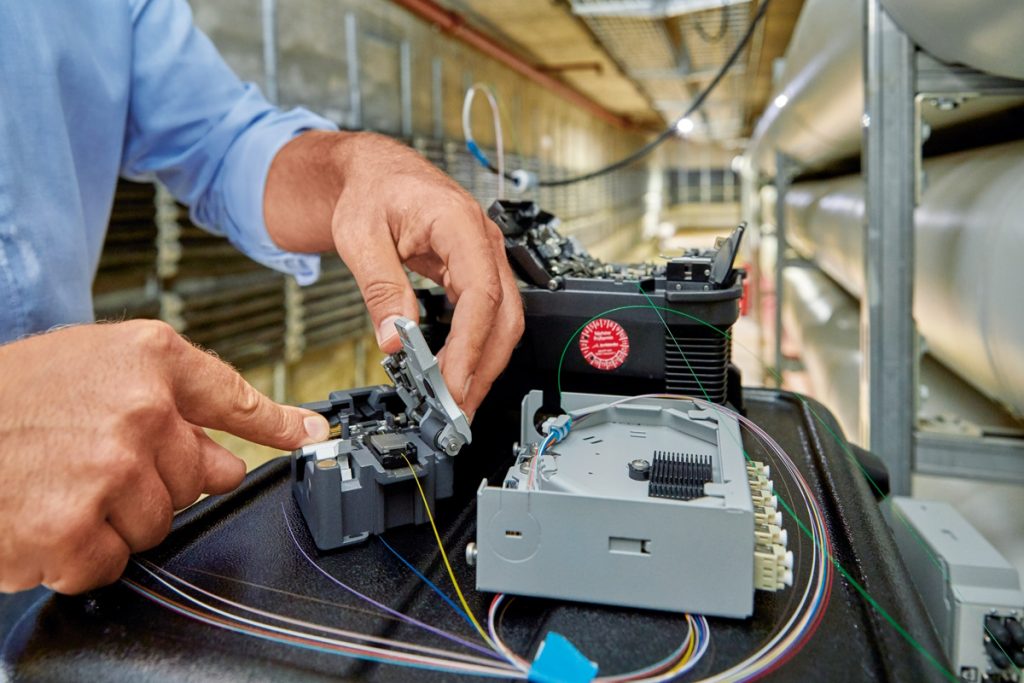

The continuity of the control cabinet building process chain is vital for efficiency and competitiveness. Untapped potential in wire preparation, identification, and wiring can be exploited through the use of optimally coordinated hand tools and automatic tools, as well as manual and automated marking systems.

Automating and bundling core processes

Automatic cutting devices, such as the Cutfox 10, can cut wires precisely and with repeat accuracy at high speed, saving time and allowing for easier stripping and crimping processes. These devices also offer flexibility in production by allowing for interchangeable dies for different types of contact. Bundling individual stripping and crimping capabilities can result in time and cost savings of up to 70%. Phoenix Contact offers a wide variety of marking solutions for wire identification, including thermal transfer printing, UV LED printing, and direct laser marking. The Thermomark E Series marking system from Phoenix Contact automates and combines the printing and applying of various marking materials in a single process step, resulting in time savings of around 60% in industrial identification. This system consists of three applicators for wire and cable identification, connected to a standard thermal transfer roll printer, eliminating the need for an additional device.

Efficiency and ergonomics

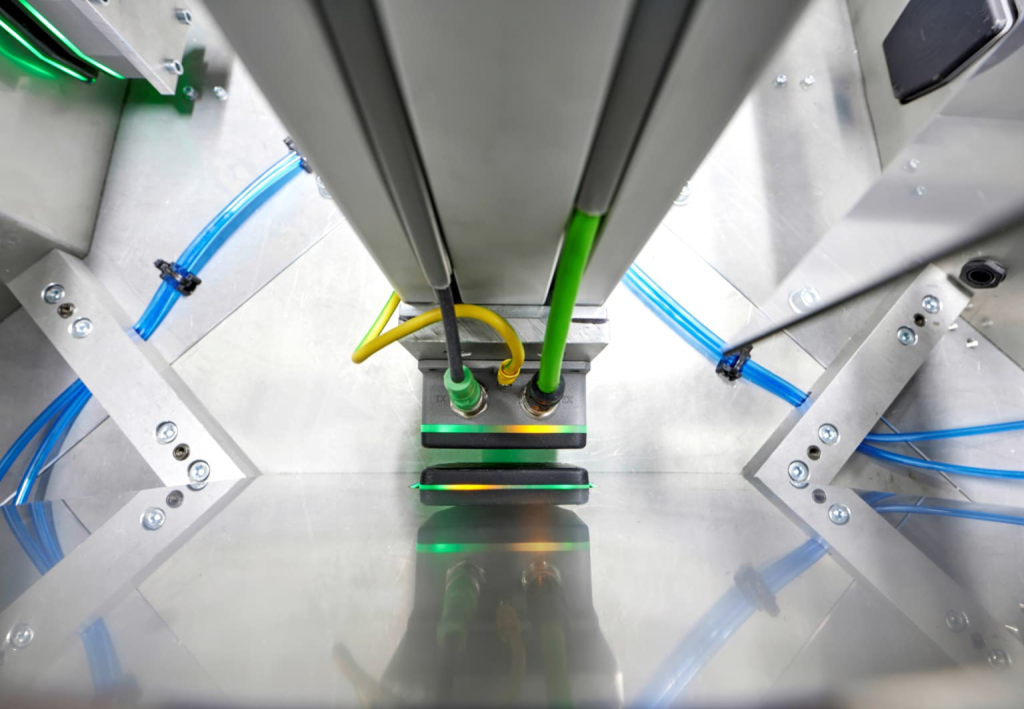

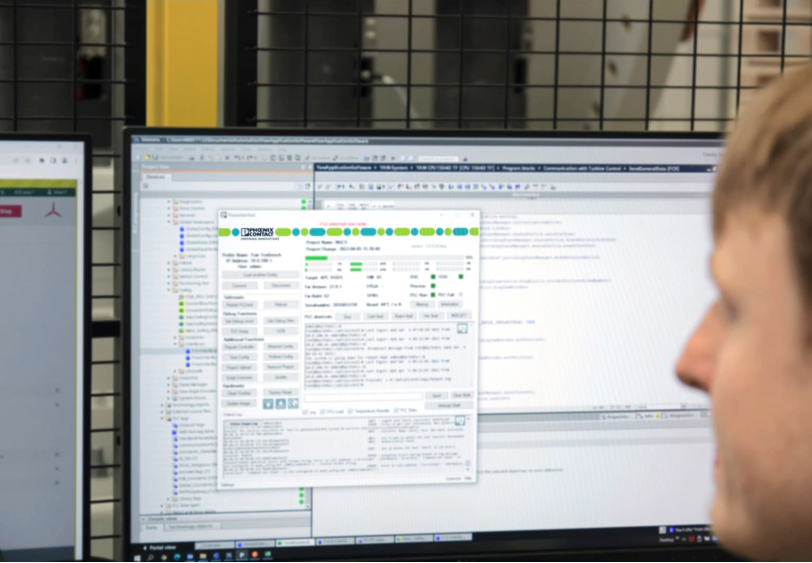

Phoenix Contact’s Clipx Wire Assist system offers a scalable, efficient, and ergonomic worker assistance system for semi-automated wire production. The system guides users through the process, controls automatic tools and printers, and displays necessary information on a monitor. The system is built around a height-adjustable workbench, allowing workers to switch between sitting and standing while working. Mounted on four industrial-grade castors, it is mobile, reducing unnecessary legwork. The modular workbench design allows users to arrange their workstation as desired, with guides attached for additional accessories.

Nothing works without data and software

Furthermore, the Wire Assist worker assistance system enhances productivity by controlling devices and guiding users through wire preparation, reducing manual effort and errors. Its intuitive graphical user interface features touch capability and a clear design. The system saves time and money by exporting necessary wiring information from CAE programs and importing it into Wire Assist. Filter and sort functions ensure efficient wire processing, eliminating unnecessary material changes.

Read more about control cabinet building.