Into the green future with the Next Generation Control System

Phoenix Contact has partnered with ENERCON. A leading manufacturer of wind turbine generators, to develop future-proof automation solutions for their platforms. The alliance focuses on enhancing pitch, azimuth, and automation systems for new platforms with the e-nacelle. Moreover, Phoenix Contact, driven by the All Electric Society’s vision of renewable energy availability and affordability, focuses on electrification, networking, and automation technologies. The partnership aims to provide expertise in the field of automation technology.

High-performance hardware including the support of high safety requirements

The wind turbine generator uses a central control system and decentral I/O stations for data transmission. The Next Generation Control System (NGCS) uses Profinet protocol and Profisafe for safety realted communication. The BPC 9102S safety PLC is the highest-performance controller, with an Intel Core i7-10700TE processor and an integrated Profisafe safety controller. ENERCON chose the Axioline system for decentral I/O modules due to its robustness and compact design. Furthermore, the AXC F XT PMP 1000 V AC extension module is also developed, measuring current and voltage grid variables with high precision. Also, provide protective devices in accordance with the VDE-AR-N 4110 and VDE-AR-N 4120 directives.

Any combination of high-level language code and model-based tools

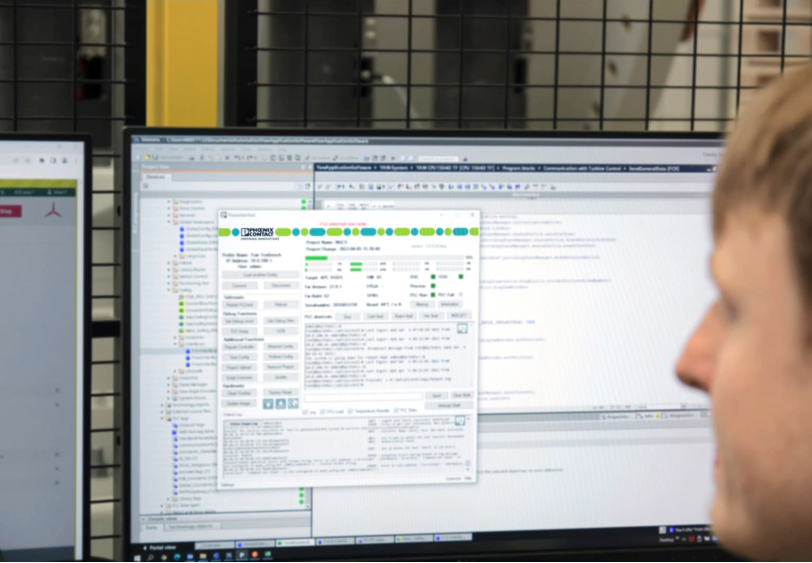

ENERCON and Phoenix Contact have partnered to develop an open PLCnext Technology ecosystem, allowing automation projects to be implemented without being subject to the restrictions of proprietary systems. The controller, based on a Linux kernel, offers real-time capability and patented task handling, reducing development time and effort. Continuous in-process testing on HIL test benches ensures system requirements are fully met. The control platform offers future-proofing and integrates technologies like OPC UA and TSN. The partnership allows for short paths to challenges and decision-making, with a support team providing active support remotely and directly at ENERCON locations and prototype construction sites.

Joint development of new technologies

ENERCON and Phoenix Contact’s partnership has resulted in the creation of innovative technologies that could significantly transform the wind industry.

Learn more about wind power.

How does the partnership aim to enhance wind turbine automation and efficiency?

Visit us Telkom University

What specific challenges in wind turbine technology are they addressing together?

Visit us Telkom University