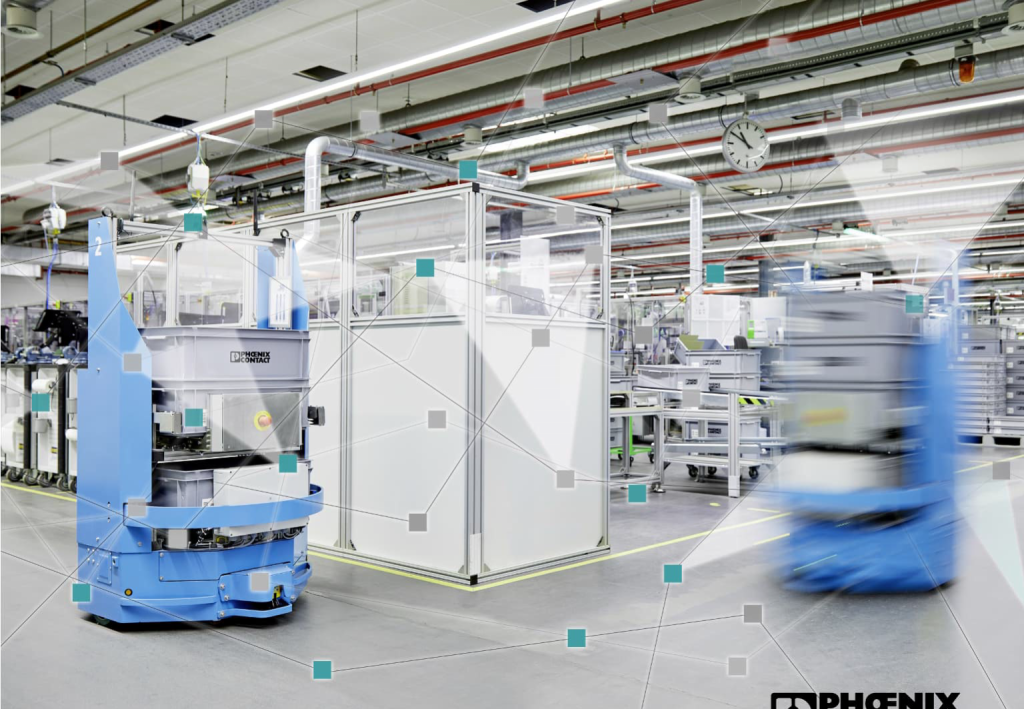

Single Pair Ethernet (SPE) is a popular industrial communication technology that enables cost-effective and space-saving connection of sensors and extends the performance of classic Ethernet. It supports IP-based communication and Power over Data Line (PoDL) for IoT devices and other applications.

SPE continuity from IP20 to M12

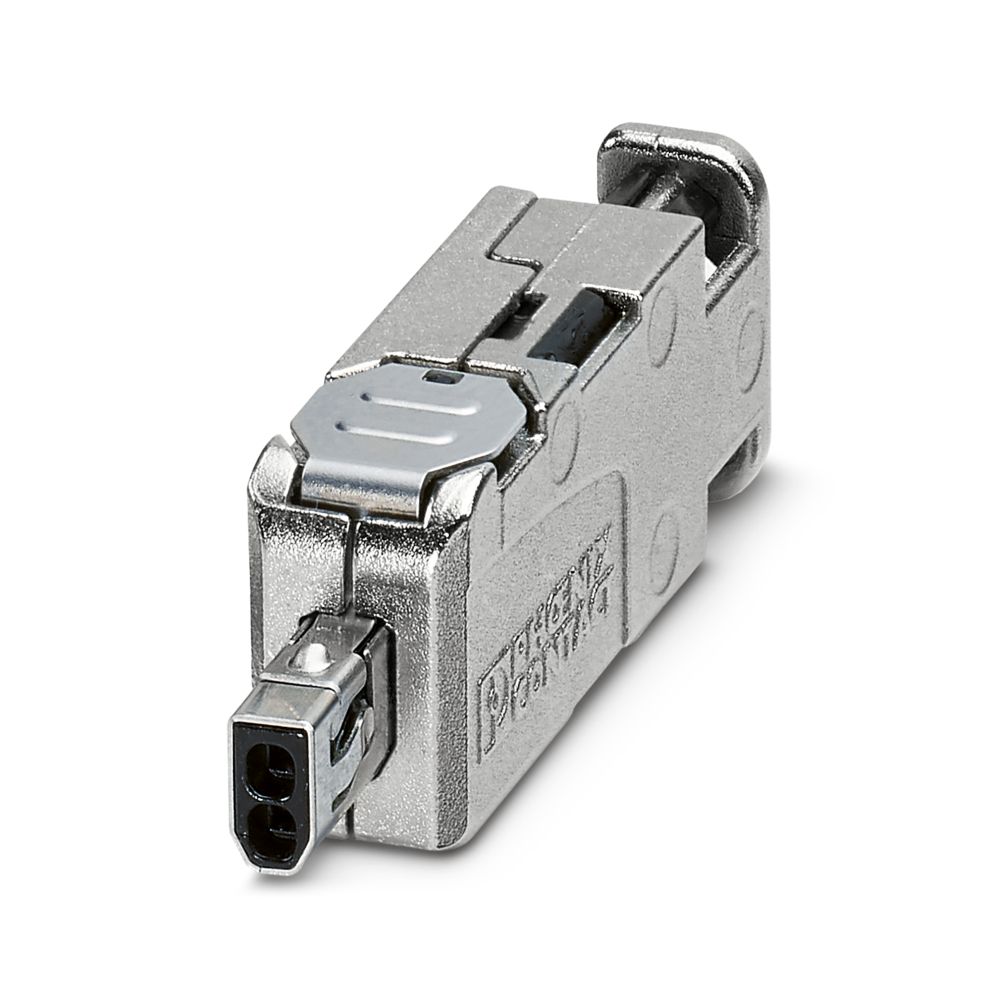

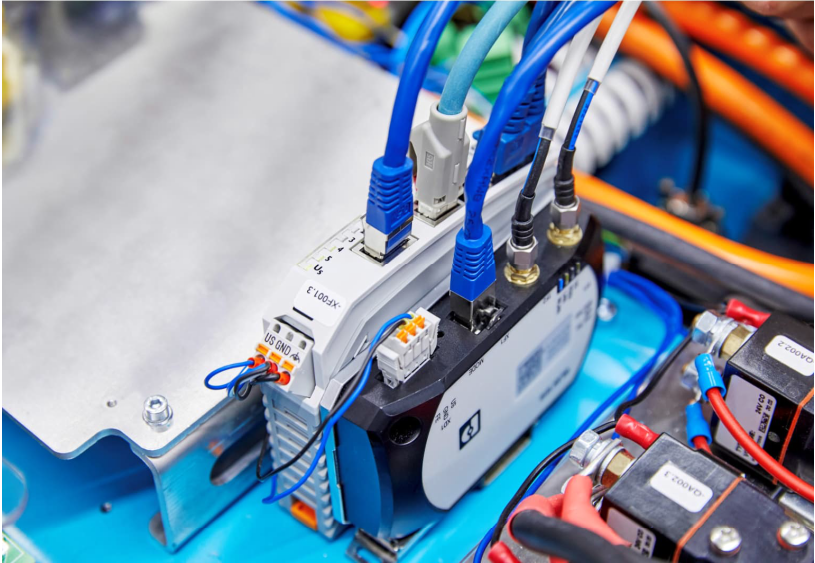

Phoenix Contact has developed connectors for SPE environments with IP20 and IEC 63171-5 for M8 and M12 versions in IP67. These connectors are user-friendly, available as patch cables or freely assembled versions. They meet industrial requirements in terms of impedance, electric strength, return attenuation, and coupling attenuation necessary in industrial environments.

Simple design-in with uniform pin connector pattern

Phoenix Contact offers IP20 and IP65/IP67 connectors with a uniform pin pattern, simplifying handling and facilitates both servicing and installation. These connectors allow for easy assembly in the system field, and their standardized M8 and M12 housing screw connections allow for seamless transition from previous Ethernet or bus systems to the current standard. They are suitable for data transmission rates up to Gigabit and meet future SPE standards.

Advanced Shielding Technology – the shielding of the future

Phoenix Contact’s Advanced Shielding Technology replaces traditional zinc die-casting for crimp sleeves with a liquid metal shield connection. This innovative method increases mechanical robustness and prevents short circuits between the shield molding and contact carrier. The technology improves M8/M12 connectors by providing robustness, availability, durability, and overload resistance. It supports Industry 4.0 and the Industrial Internet of Things, supporting miniaturization in field and device cabling.

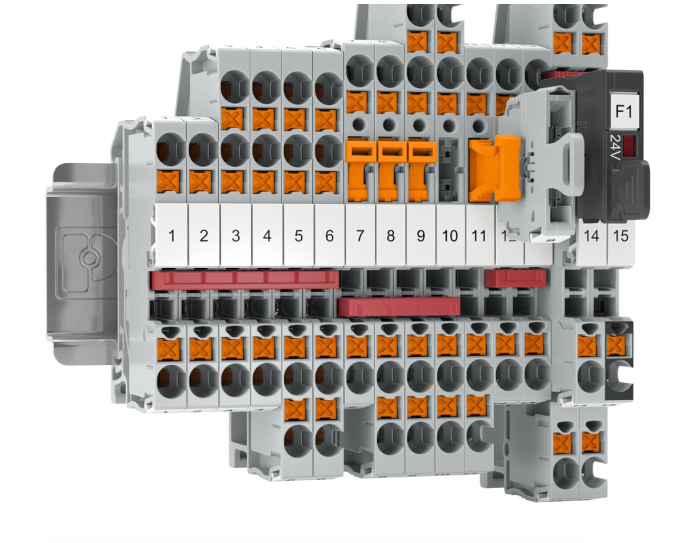

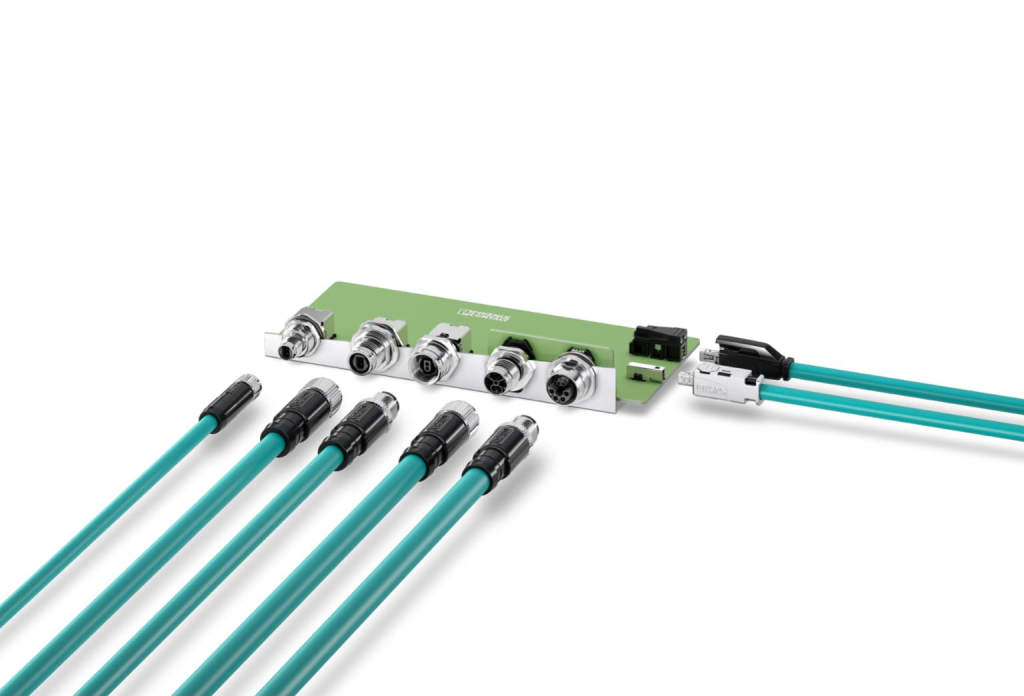

PNO supports SPE pin connector pattern of IEC 63171-7 for hybrid applications

The PNO guideline for “PROFINET Cabling and Interconnection Technology – Guideline for PROFINET Version 5.3” has defined hybrid M12 Single Pair Ethernet as the new pin connector pattern, marking the first time a user organization has opted for an SPE pin connector pattern..

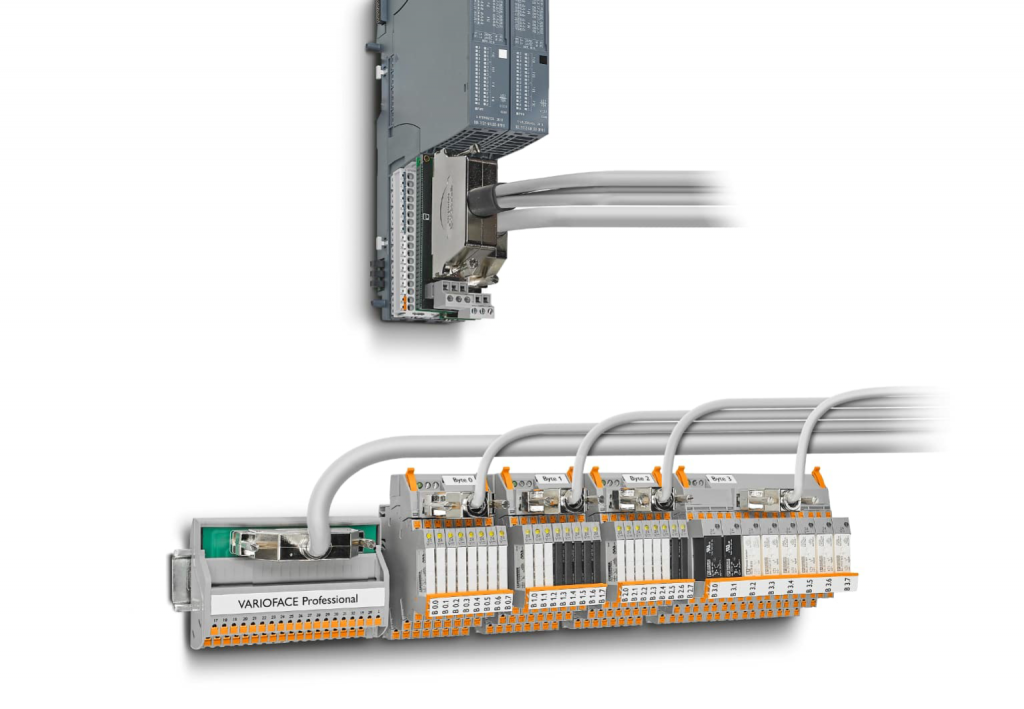

M12 Hybrid – the perfect addition to PoDL

Single Pair Ethernet (SPE) offers the advantage of integrating power supply and data transmission via the same cable, making it ideal for supplying power and data in confined spaces. Phoenix Contact Group and TE Connectivity have developed SPE M12 hybrid connectors in accordance with IEC 63171-7, enabling hybrid interfaces with SPE and power contacts in M12 format. SPE is particularly beneficial in robotics, as it combines flexible and space-saving wiring with fast response times. SPE M12 hybrid interfaces integrate seamlessly into existing Ethernet infrastructures and offer simple plug-and-play connections.

Learn more about Single Pair Ethernet.