Automation and electrification from a single source

Green hydrogen is set to replace fossil fuels in many industries, and Enapter AG has developed the AEM Multicore to make production cost-effective and flexible. Phoenix Contact experts assisted in engineering, programming, and outfitting the electrolyzer system with key components for automation and electrification. Green hydrogen’s intrinsic value stems from its ease of storage and on-demand transportation. Enapter specializes in AEM “anion exchange membrane” electrolyzers, which are more cost-effective than PEM electrolyzers while being just as flexible. The company plans to mass-produce these stacks in the medium term using a highly automated process.

Fully developed AEM stacks for series production

Enapter has introduced the AEM Multicore 450, a modular, preassembled container capable of producing up to 450 kilograms of hydrogen per day. The multicore consists of 420 AEM stack modules, each with a 2.5-kilowatt power, allowing for greater flexibility and greater process redundancy. The container also includes power supply, regulation of the electrolysis process, heat dissipation, and monitoring of process parameters, including hydrogen purity, through sensors. The fully developed stacks have already been sold in large quantities.

Close collaboration in the area of functional safety

Phoenix Contact supported Enapter, a company that developed a power supply and controller for a 1-megawatt system. The company’s services range from the development of the first small test system to the commissioning of the 1-megawatt system. Phoenix Contact’s project manager, Ayhan Birinci, highlighted the importance of functional safety in these projects. The team started working on a risk assessment before the design phase, which laid the foundation for essential design elements, including the controller. The software for the safety controller was compiled by Phoenix Contact engineers. Andreas Lautmann, Business Development Manager for power-to-X, emphasized the importance of a structured, well-documented process for design and engineering for the safety of the overall system. Furthermore, two Phoenix Contact programmers assisted the Enapter team in building a smaller test system with ten electrolysis stacks.

A challenging market situation, particularly regarding microchips

The team worked on planning control technology, which was revised seven times before the control cabinets were built. The departure of the original system planner in spring 2022 added extra work. The final changes were made during the design freeze in December 2022. Constructing the control cabinets was challenging due to supply chain issues, particularly with microchips. Phoenix Contact and Enapter worked together to keep the ambitious commissioning date, with the AEM Multicore 450 system inaugurated on May 24, 2023.

Control cabinets fully equipped with Phoenix Contact components

Phoenix Contact has installed components and systems in an electrolyzer, including connectors for sensors and controllers, and a PSU compartment for control. The control cabinets are equipped with Phoenix Contact components, including real-time and safety-oriented control technology up to SIL 3. The superordinate system controller is built with PLCnext products, fulfilling functions like ventilation, water pretreatment, emergency shutdown, fill level monitoring, and electrolyte solution supply. In-house 24 V DC power supplies, signal converters, and connection technology are also included.

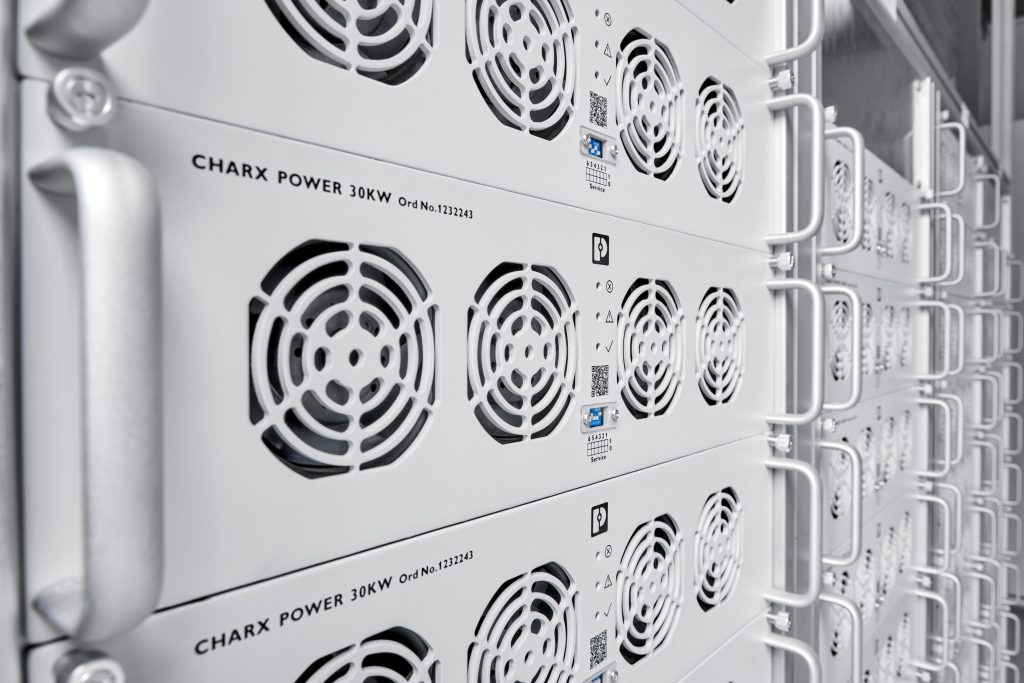

Compact AC/DC converters

Phoenix Contact’s Charx power system converts 400-volt AC voltage into direct current for electrolysis. The original converters were not suitable for controlling electrolysis, leading to a replacement with a Charx series converter. The converter is more compact and efficient, ideal for installation in larger systems. Enapter ordered a complete set of AC/DC converters in mid-2022, enhancing efficiency and optimizing the PSU compartment’s cooling system.

Smooth modification of the first system

Enapter has received orders for seven more AEM Multicore systems since its first system was inaugurated in May 2023. Phoenix Contact is also able to play its part here by supplying a complete solution package of services. Enapter CEO Sebastian-Justus Schmidt stated that AEM technology will make hydrogen more economical than fossil fuels. Pre-series maturity for AEM Multicore is projected for 2024 due to strong demand. Andreas Lautmann expects IT security importance with IEC 62443 certification and integration into existing systems.

Find out more on our website.

How has Enapter’s AEM technology impacted the hydrogen industry, and what are the projections for its future, including pre-series maturity and IT security measures? Regards, Telkom University/a>