The use of battery energy storage systems in power-to-X applications

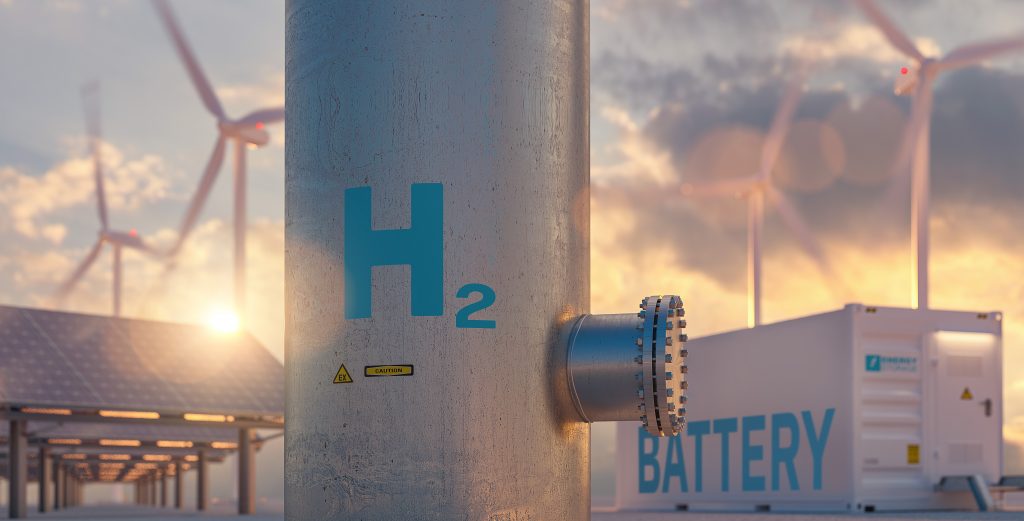

The All Electric Society concept describes a future where renewable energy is the primary source of electricity worldwide, affordable, and abundant. Energy storage technologies, such as power-to-X and battery systems, are crucial for this vision, with the greatest potential in battery energy storage systems and green hydrogen production.

Power-to-X as an energy storage technology

Hydrogen is stored in renewable energy through electrolysis, breaking down water into hydrogen and oxygen. This gas is compressed and stored in tanks. When electrical energy is needed, hydrogen reacts with air in fuel cells to form water, We refer to this process chain as power-to-X technology. The term generally refers to the conversion of surplus renewable energy into other energy carriers.

Battery energy storage systems

Battery storage efficiently stores electrical energy through chemical conversion in galvanic elements, allowing current to flow through electrodes connected via an electrical load.

Short and long-term storage

Battery storage differs significantly from power-to-X processes, as batteries require large, expensive batteries with precious materials. Unlike hydrogen storage, which is less expensive and has a higher energy density, power-to-X technologies have lower conversion efficiency due to waste heat generation. However, battery storage has over 90% efficiency, making it suitable for shorter storage periods, such as hours or days. This makes battery energy storage more economically viable for long-term storage.

In combination lies strength

The hydrogen process and battery differ in inertia, with batteries storing energy quickly and electrolyzers and fuel cells requiring power proportional to reactor size. Both operate at maximum efficiency within a small process window, avoiding major fluctuations. Combining these technologies can provide hybrid solutions for stationary or quasi-stationary electricity generation, covering consumer base load and battery for short-term load fluctuations. Electrical connection technology ensures efficiency and reliability.

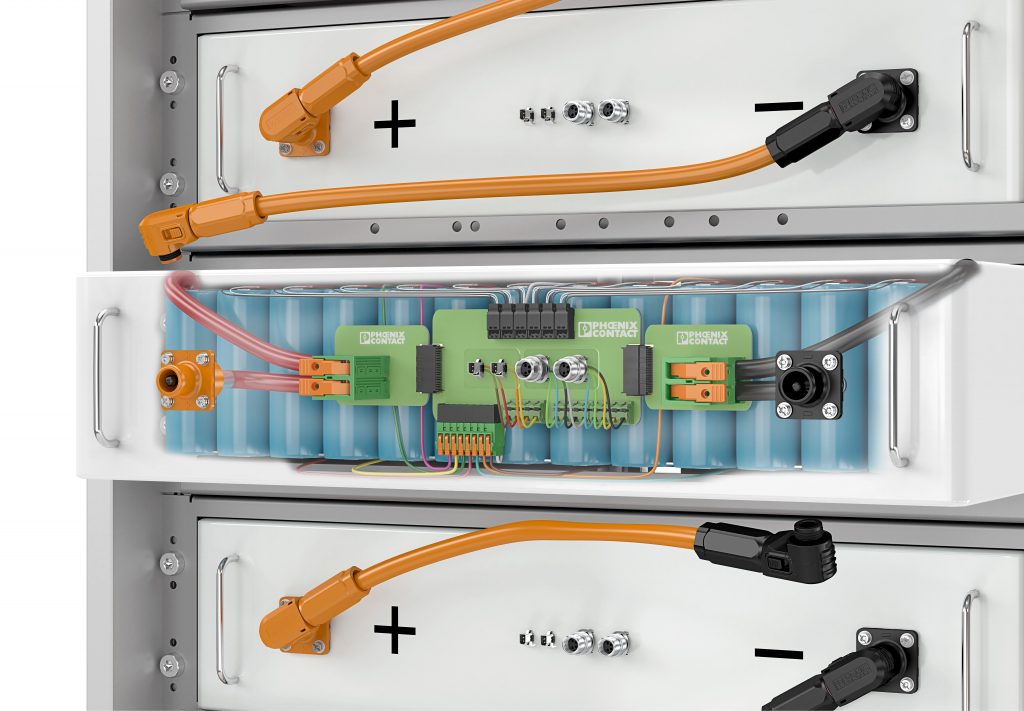

The role of electrical connection technology

Electrical connection technology is crucial for efficiency and reliability in batteries, electrolyzers, and fuel cells. It requires power, signal, and data connections, with analog signals controlling sensors and digital communication systems.

Examples of faults in the connection technology

Inconspicuous components like power wiring, signal connections, and data connections are crucial for system safety. Classic screw connections can loose in unfavorable conditions, leading to increased contact resistance and heat loss. Signal connections, such as sensor cables, can be soldered directly, resulting in cold solder points and incorrect temperature measurements being too low. Data connections, often created using patch cables, can also cause faults during transmission, leading to system malfunctions and hardware damage.

Recommendations for selecting connection technology

To avoid financial losses, system operators should use plug-in connectors for power connections when installation conditions cannot be guaranteed. Innovative connection technologies like insulation displacement connections offer convenience and reliability. For data connections, ambient conditions dictate requirements, with IP-protected data connectors ideal for high pollution or humid environments and industrial-grade connectors for tough mechanical conditions.

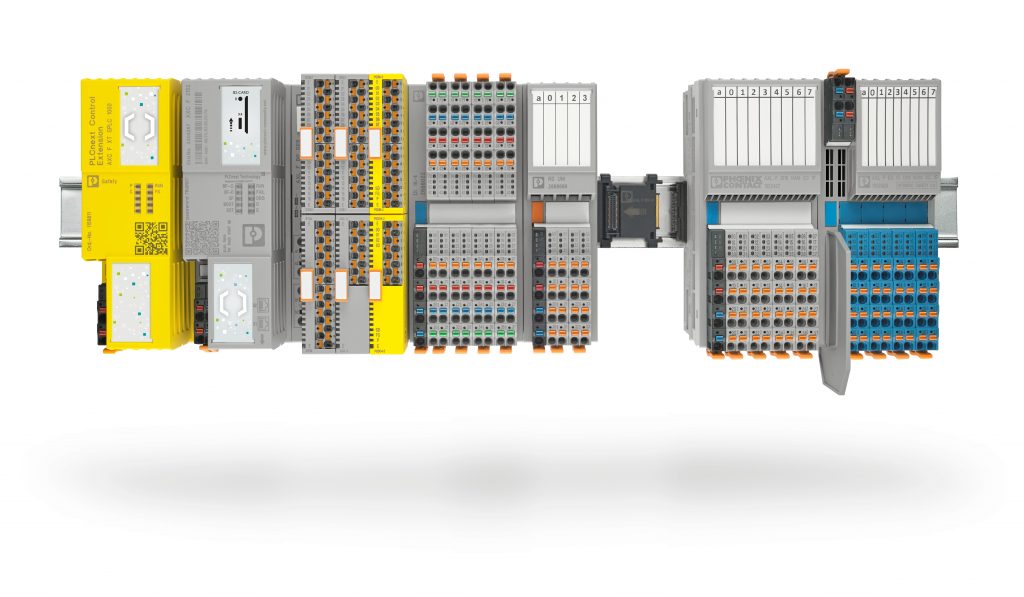

The importance of modular automation systems in energy storage applications

Battery-based and hydrogen-based energy storage solutions are complex systems with functional safety, IT security, and explosion protection requirements. Automation systems aim for optimal control of subsystems, considering user objectives, minimum operating costs, service life, and availability. Compliance with grid connection conditions is also crucial. Simulating system design in advance is advantageous. A modular, scalable automation platform with relevant certifications reduces development times and costs for energy storage applications. Automation suppliers offer comprehensive services, including safety concept creation, IT security considerations, and programming.

Learn more about Solutions for electrification, networking, and automation in the power-to-X and hydrogen industry. and Connection technology for energy storage systems.