A Digital Factory approach that conserves resources and is economical at the same time

Phoenix Contact focuses on sustainability and balancing its carbon footprint by developing automation solutions. The company aims to help other manufacturing companies achieve carbon neutrality by electrifying loads, creating energy transparency, and using renewable energies in daily operations. The All Electric Society concept describes a future where renewable energy is available worldwide in sufficient quantities and economically. Phoenix Contact’s holistic digitalization concept, “Digital Factory now,” integrates consumption data into distribution, visualization, and control of process data, aiming to control energy consumption and achieve carbon-neutral production.

Recording, evaluating, and managing loads

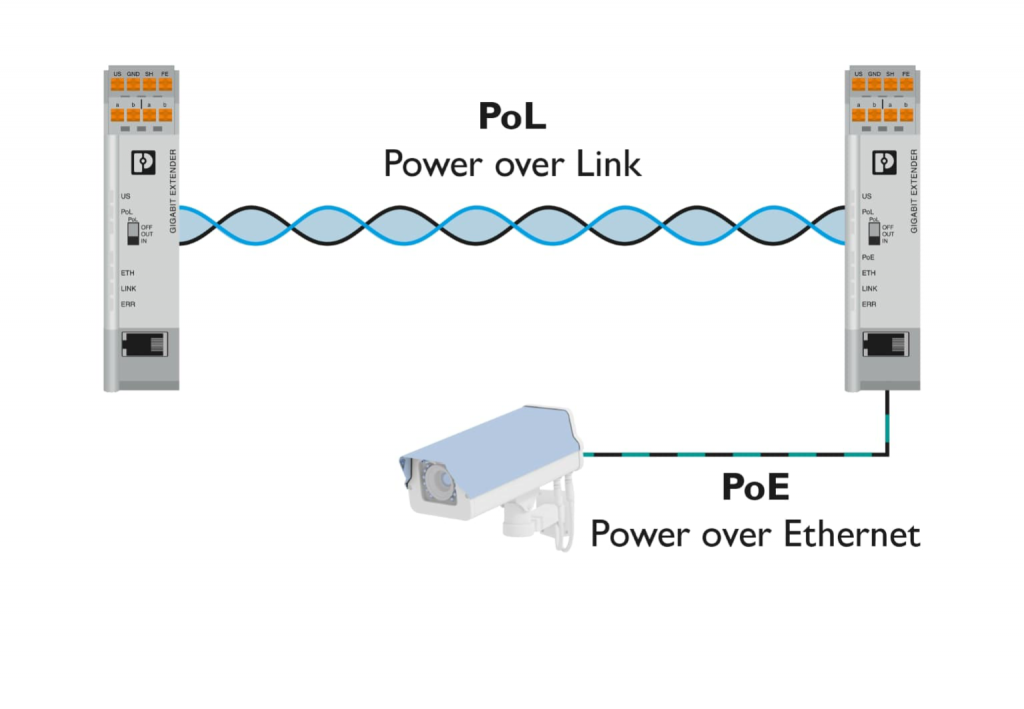

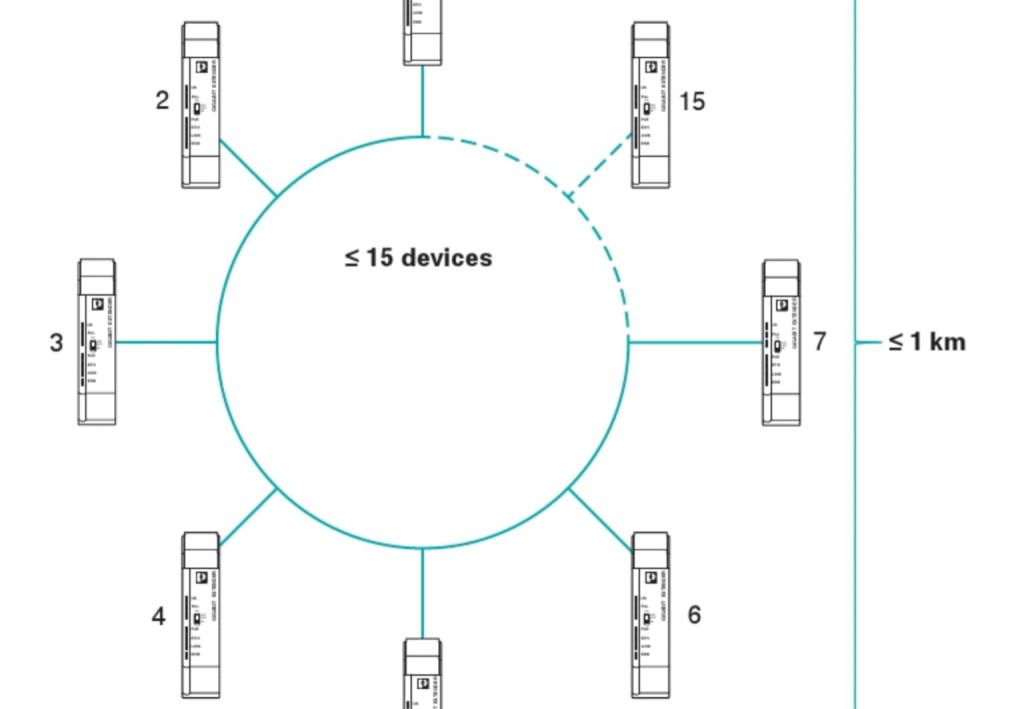

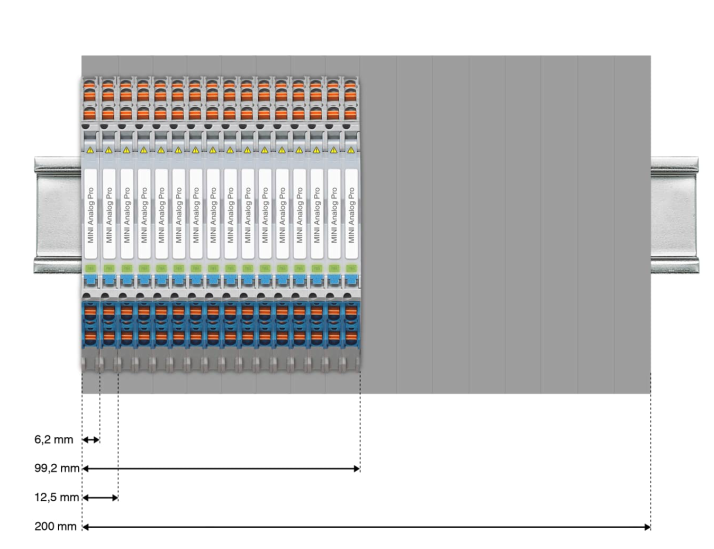

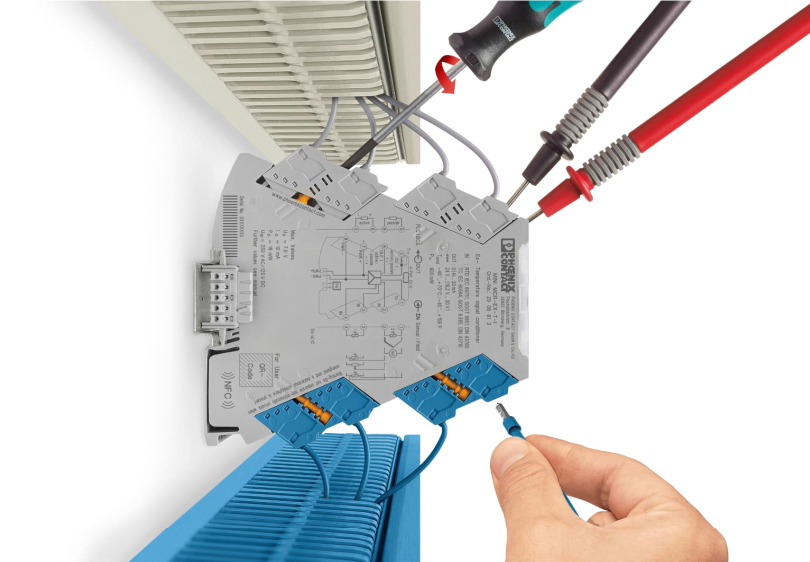

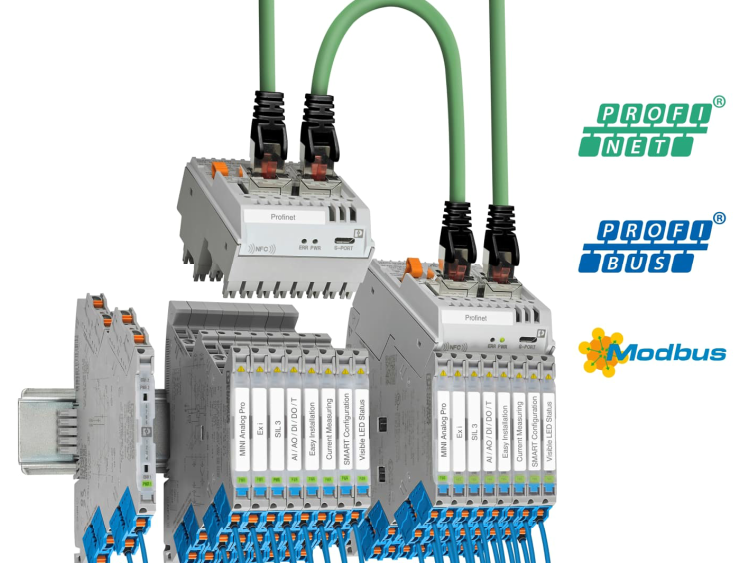

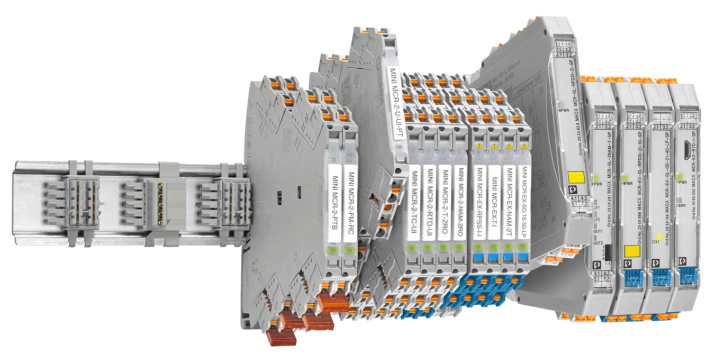

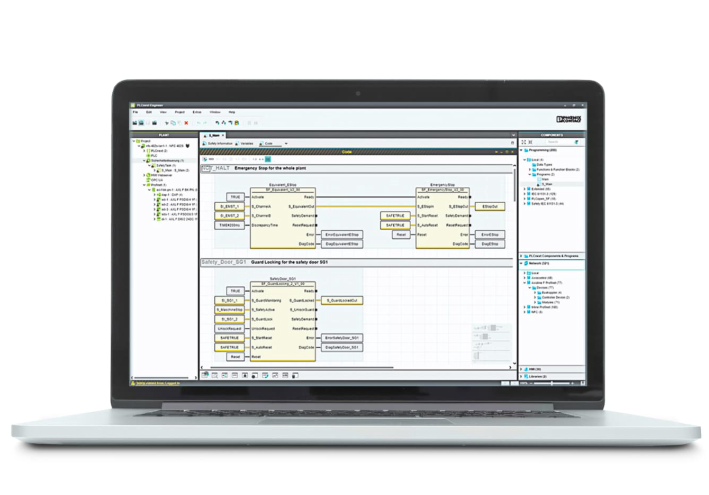

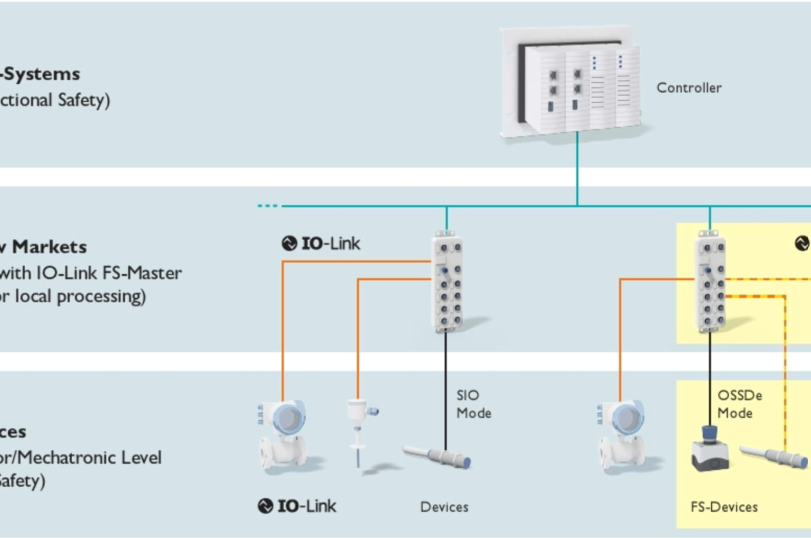

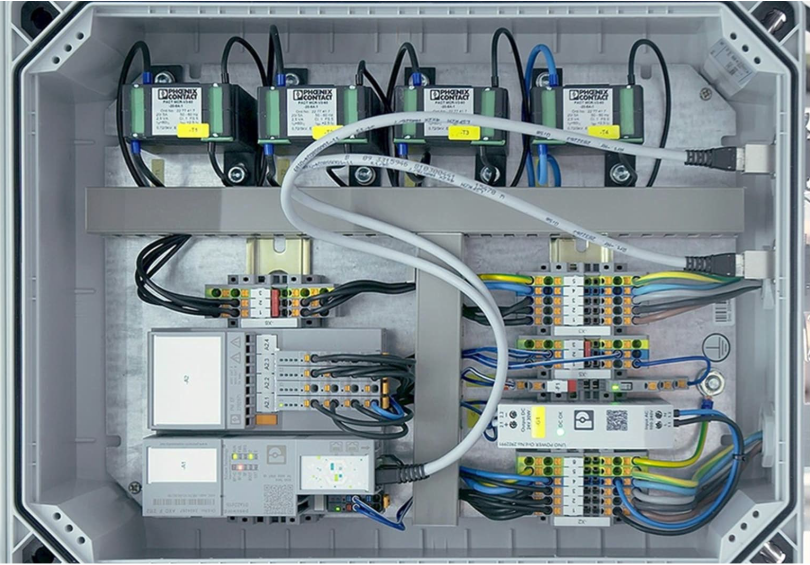

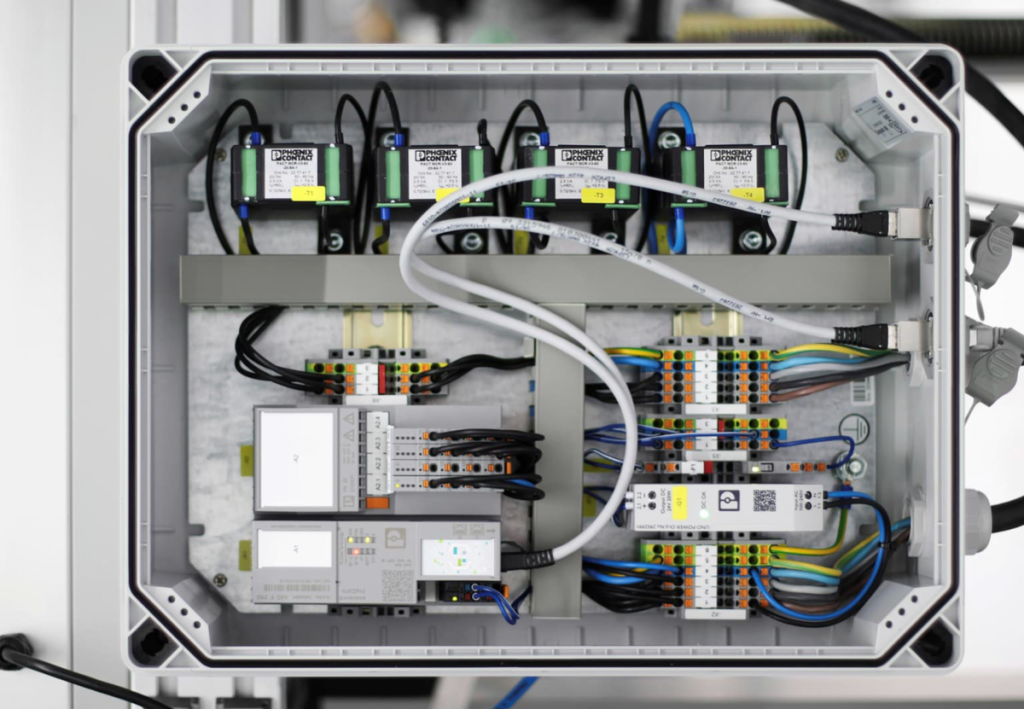

Phoenix Contact has developed an architecture called “More than Measure Energy” to integrate existing systems into modern IT systems. This architecture includes a Data Collection Box for secure integration of process and consumption data. Users can choose between a standardized Data Collection Box or a fully customized version. Phoenix Contact uses a programmable logic controller (PLC) from the PLCnext Control product family in its Digital Factory at the Bad Pyrmont location for secure communication with the OT world and IIoT devices. The company also provides solutions in the immediate production environment as well as its own EMMA cloud service for energy management.

Turning findings into optimization measures quickly

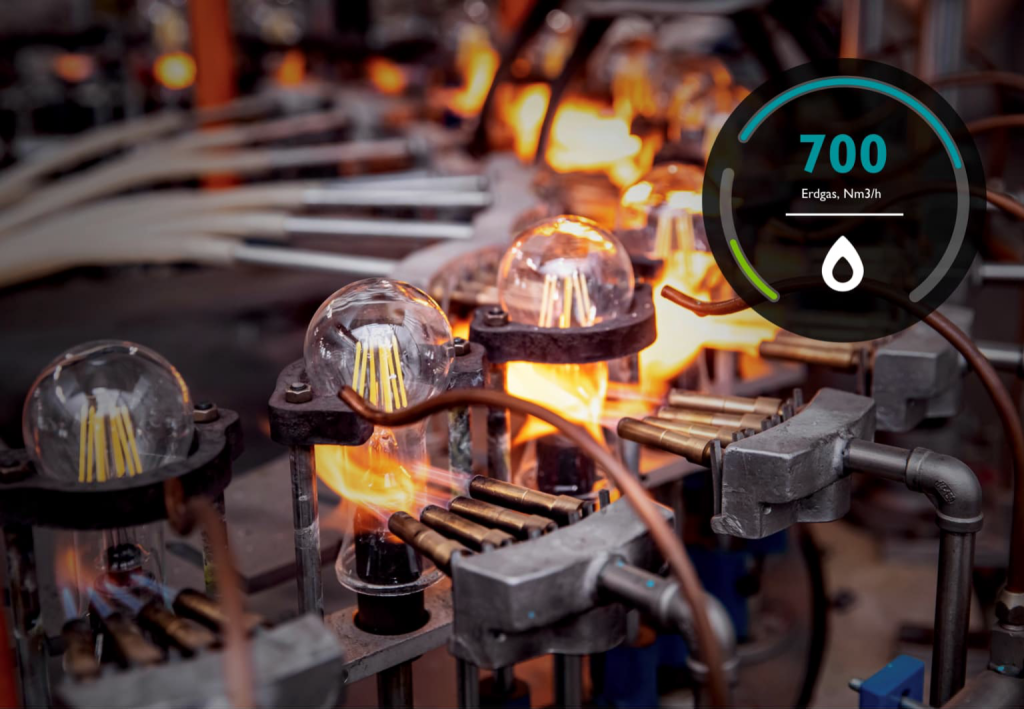

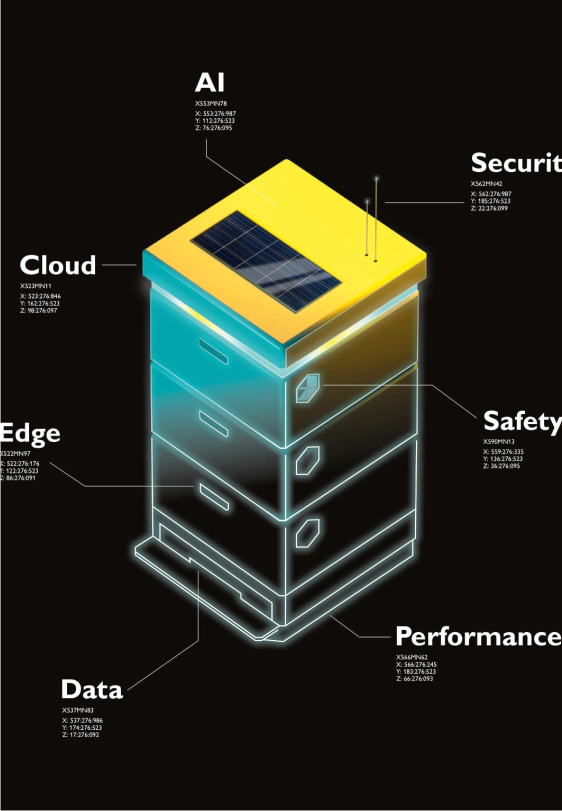

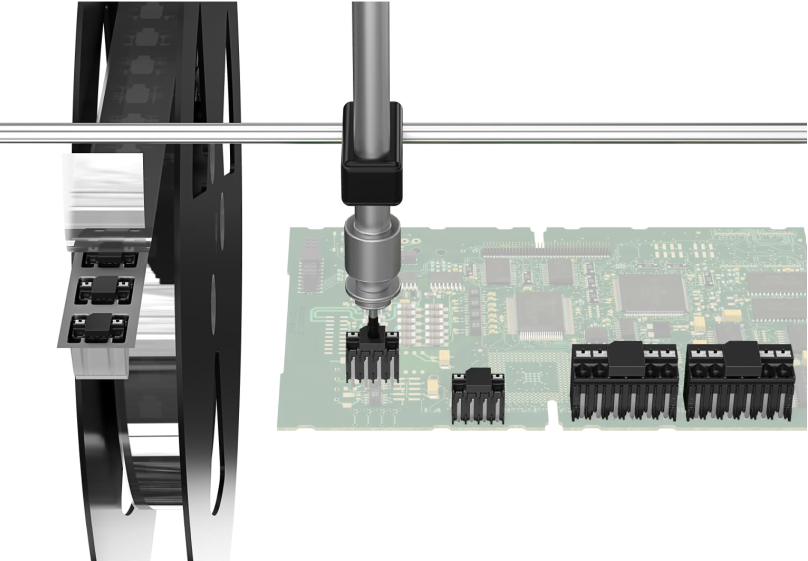

A soldering system in the Digital Factory in Bad Pyrmont integrates energy-saving measures by analyzing energy data from a Data Collection Box. The system identifies standby energy consumption and allows for dynamic switch-off and switch-on times based on order data and energy data analysis. This allows for more efficient order planning in the long term. Phoenix Contact’s “MLnext” machine learning solutions can help predict field-level information, such as manual workstation utilization status, ensuring data availability. A holistic approach to optimization involves collecting and analyzing data throughout the entire production process using AI-based algorithms.

Energy data reflects the system behavior

Energy data can be used to evaluate machine performance, availability, and product quality using artificial intelligence (AI). Anomalies can be detected and quantities and operating states can be predicted. Collecting and storing data benefits users differently, accelerating the payback period and revealing potential. The Big Data approach applies, focusing on data-driven patterns and providing suggested solutions to domain experts. Collecting energy data leads to direct and indirect benefits, ensuring resource-efficient and competitive production.

Find out more about Digital Factory here.

Find out more about PLCnext.