One of the main difficulties the metalworking industry has had to overcome over the past 50 years is producing “lead-free.” Phoenix Contact recognized their responsibility to decrease lead exposure early on in order to safeguard public health and the environment. We set this objective with the intention of significantly improving life quality. To accomplish this, the company tried numerous of its own production methods as well as dozens of other materials.

Lead is a heavy metal that harms human health and builds up in the environment and in living things. Therefore, most products and fuels no longer contain it.

For the producers of electronic goods, this fundamental revolution is still to come. Phoenix Contact already established this goal for itself early on and will be able to provide lead-free versions of the majority of its circular connection product line this year.

Every product, every process under scrutiny

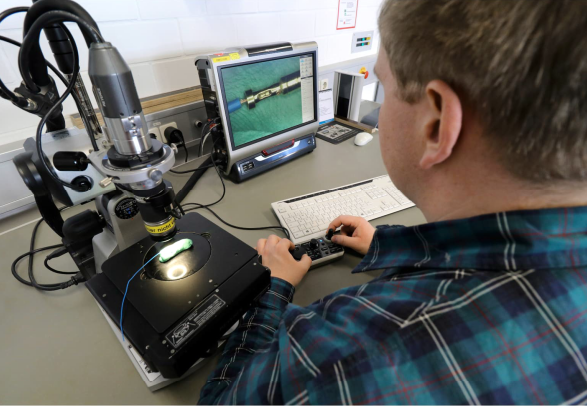

Phoenix Contact project participants have been collaborating across regions for many years to find appropriate materials and modify production techniques. To explore this subject from scientific perspective, Phoenix Contact participated in research project started at the RWTH Aachen University. For diverse lead-free copper alloys, the participants here established fundamental processing techniques. This served as the foundation for the technology’s real development at the Blomberg facility.

The investigations revealed, among other things, that alloys without lead performed chip breaking less effectively than those that did. Lead not only enables good chip breaking in normal industrial production processes, but it also facilitates cold forming and ensures simple lubrication in the material. Without lead, these characteristics deteriorate.

From that point on, production and the technology laboratory had to constantly exchange ideas in order to find the ideal material, which had a scientific basis. For instance, if a copper alloy contained less zinc, its machinability attributes increased but its capacity for cold forming declined. The crimp connections were the focus of the product designers’ attention since they needed to have strong electrical conductivity, be long-lasting, and also have good machining and cold-forming capabilities. The search was a delicate balancing act that called for close coordination between suppliers, technological labs, product developers, and the department in charge of series production.

Phoenix Contact made an investment in its own production equipment for its test series using lead-free alloys to prevent continued production from slowing down due to intensive material testing. The business even created a brand-new method for chip cracking and submitted a patent application.

The European RoHS Directive

European RoHS directive have already restricted or even outright banned several substances that negatively impact environment. However, certain dangerous compounds are not yet replaceable due to their technical characteristics. For example, lead is still authorized in Exception 6c in Annex III of Directive 2011/65/EU up to a mass percentage of 4%. RoHS Directive set an end to this exception on July 21, 2021. From that point on, it would have been illegal to sell electrical and electronic equipment in Europe if the material included more lead than 0.1 percent.

Similar laws are in place in several nations. The “China-RoHS,” ensures equivalent material bans in China, whereas Switzerland has passed the ChemRRV (Chemical Risk Reduction Ordinance). Lead is on the list of compounds of concern in the “Japan RoHS,”. However, South Korea has accepted a significant portion of European standards in the “Korea RoHS.” In the United States, similar regulations are also in the works. Phoenix Contact has finished the technical and process engineering preparations needed to offer lead-free products, regardless of whether the European Union renews the exclusion clause or not.

Changing processes soon enough

The switch to lead-free copper alloys for the electronics sector is a massive undertaking, much like the switch to unleaded fuels. It would take decades to complete the work required, not years. The responsible planners must quickly adjust electronic equipment and take lead-free components into account while planning. Anyone designing products today who does not want to painfully renew certifications for the product in the coming years should take the RoHS issue into account early on when choosing components.

Given this, Phoenix Contact is already in compliance with current legal specifications and demands. Developers can already plan future-proof devices that simultaneously safeguard both the environment and people. To this purpose, thousands of products already have lead-free versions available.

There is currently a sizable assortment of lead-free circular connectors available from Phoenix Contact. Thanks to the constant expansion of the metric M5 to M58 series a nearly lead-free product range will be accessible.