Meeting individual customer needs in batch size 1 poses major challenges for production and data processes. Phoenix Contact’s unique process architecture enables fast, requirement-driven delivery of tailored products even in the smallest quantities through configuration.

The problem: Real-time availability of data and information – even with a tailored configuration and a batch quantity of 1

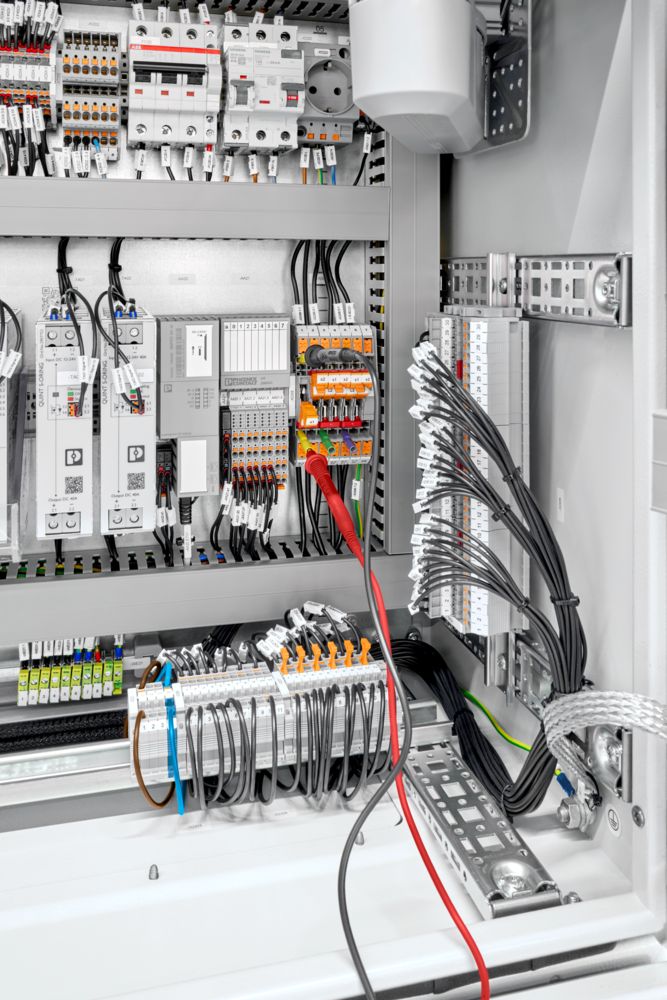

As customer expectations evolve, there is a growing demand for tailored, needs-based solutions in batch size 1—delivered both quickly and affordably. Consequently, manufacturers face mounting challenges in achieving efficient fulfillment, particularly in control cabinet building, where limited project scopes and short cycles provide minimal flexibility. At the same time, the need for immediate access to technical and commercial item data continues to rise.

Digital configuration of the smallest quantities and end-to-end production

Phoenix Contact’s configurators enable real-time, effortless customization and ordering. Digital assets like data sheets, drawings, and CAD files are instantly available on the website. This is powered by the Digital Process Framework—a holistic system for automating and orchestrating processes from configuration to item creation, pricing, and data provision.

Customers configure products directly on the website—no installation needed. A guided, intuitive 3D configurator narrows options and ensures error-free, compatible results. Upon completion, a detailed data sheet with images, drawings, and CAD files is instantly downloadable. A solution ID allows easy reloading and editing. Registered users can order directly via the shopping cart. In contrast, traditional project-based customization involves multiple departments, semi-automated systems, and longer processing times.

Clicking the shopping cart in the online configurator triggers automated item documentation and displays the item number in real time. Availability and pricing are shown instantly, and item details appear under the new number in the web shop. This single action initiates a seamless, orchestrated process: configuration data flows to backend systems, ERP records are created, and production documents are stored in the PLM system. These documents are immediately downloadable and integrated into automated production and quality checks of the individually manufactured item.

Fully exploiting the potential of the modular Fix block system through configuration

Phoenix Contact’s Fix block system offers an ideal solution for customized power distribution needs, with modular options for size, versatility, operation, and mounting.

The system includes monoblocks and distribution blocks with up to 18 connections and a feed-in contact. Variants features disconnect functions, fuse elements, and plug-in options for wired components. For space-saving conductor feeds, blocks offer horizontal and vertical connections. Compact device terminal blocks with up to 5 separate potentials complete the range. All blocks come in 11 colours and support conductor cross-sections from 0.14 mm² to 16 mm².

The Fix block system offers flexible mounting on NS 15 and NS 35 DIN rails, both vertically and horizontally. Additional options include screw flange, securing pin, stick-on, and overhung mounting. Blocks can be easily joined mechanically into compact units, with electric bridging enabled by standard Clipline complete accessories.

With just a few clicks, the Fix block configurator allows creation of tailored solutions, including custom marking applied during production. Item data is instantly available and can be accessed directly from the clipx Engineer software, enabling seamless integration into the engineering process. This streamlined approach replaces the need for separate item numbers and on-site assembly—now, a complete solution is ordered under one material number and installed immediately. The result: reduced ordering effort, simplified logistics, faster installation, and significant savings in time and cost.

Configurator portfolio increases efficiency potential

In addition to the Fix block system, the Digital Process Framework further supports online configuration for the FAME test system, custom transformer terminal strips, and the Combi connector family. Looking ahead, the portfolio will continue to expand with additional products and applications.

This end-to-end process chain supports batch size 1, leveraging digitalization to boost customization potential and reduce costs.

Read more about configurators