From the circuit diagram to the control cabinet

Control cabinet manufacturers face increasing challenges such as time and cost pressures, shortage of skilled workers, and long component lead times. Engineering software clipx Engineer helps with the planning and completion of control cabinets. Phoenix Contact is working with manufacturers to identify inefficiencies in planning and manufacturing processes, as well as media discontinuities between engineering and paper-based productions.

Planning – starting point for continuous production

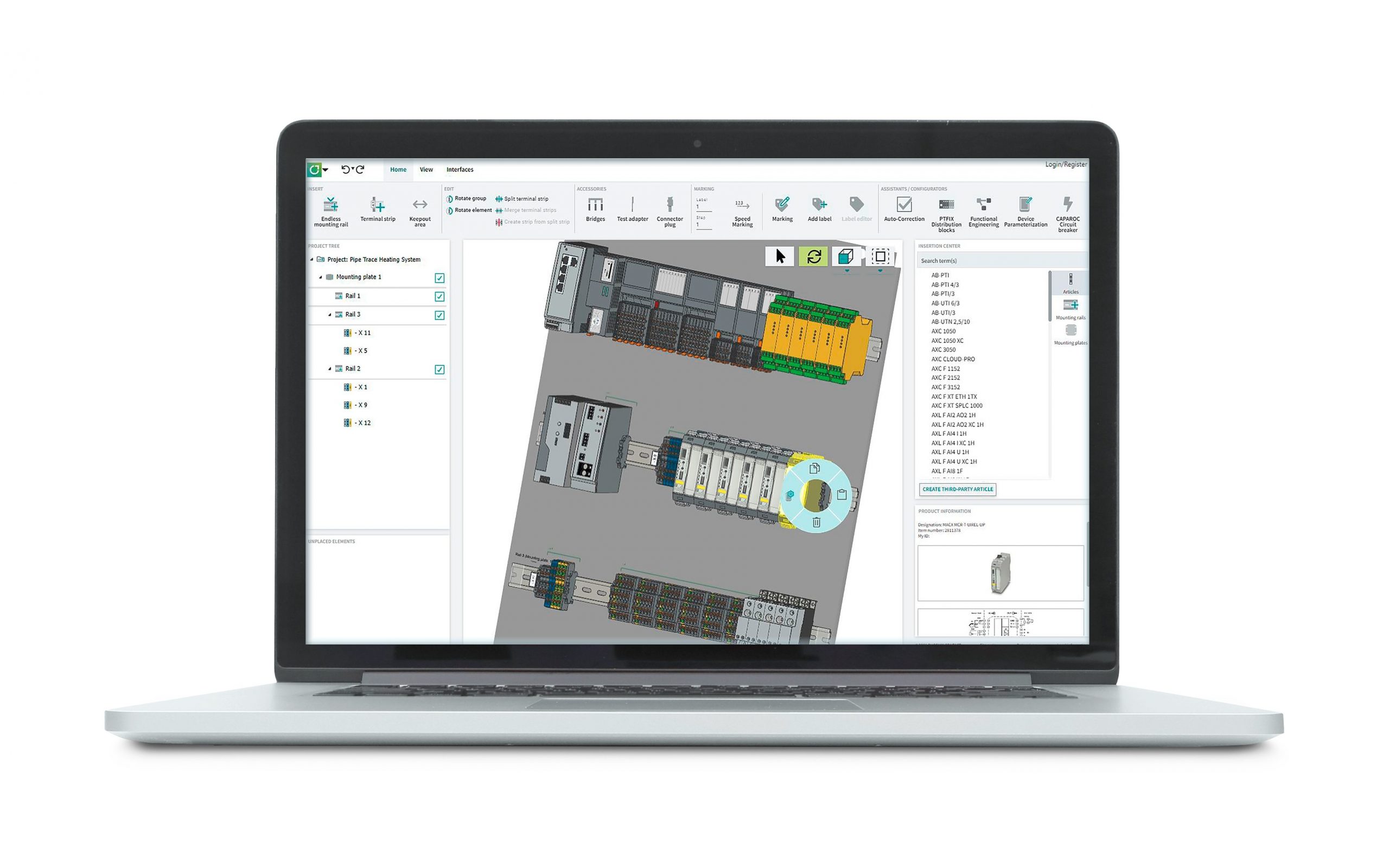

Digital control cabinets can be shared effectively through computer-aided engineering (CAE) systems, which can create circuit, assembly, and wiring diagrams. Engineering software like clipx Engineer from Phoenix Contact can acquire components, parts, functions, connection cross-sections, and labeling information, and display them digitally. The software also assists in assigning accessory items, such as covers and end brackets, and provides configurators for finding necessary components. Clipx Engineer also handles tasks like inserting and setting up terminal blocks, which can be time-consuming. The software also writes data back to the leading CAE system using a two-way interface, recording it at connection points. This saves wiring time and requires fewer connection lines, reducing terminal points on terminal blocks. The engineering software serves as the central digital database for different control cabinet variants.

Uses of the generated data for the subsequent process chain of a control cabinet manufacturer

Digitally described terminal strips or control cabinets can be assembled or equipped using Phoenix Contact’s worker-assistance software in production. Consequently, this process is more efficient and consistent with clipx Engineer engineering software. The information is displayed on a screen, assisting in assembly. A pick-by-light system can be connected for additional support, eliminating the need for time-consuming document interpretation and component search. Semi-skilled employees can perform these work steps, allowing for a more focused focus on qualified work.

Learn more about clipx ENGINEER.