Requirements on surge protective devices in signal processing networks further increased

Transient overvoltages can damage sensitive electronics in signal networks. Surge protective devices (SPDs) safeguard against these disturbances and maintain high system availability.

Signal applications typically operate at low voltages and short-circuit energies, so SPD overloads or aging rarely pose critical risks. However, higher voltage or current applications may require more than just backup fuses. To address this, IEC 61643-21 introduces additional safety tests and measures to ensure SPD reliability under stress.

Relevant for SPDs with more than 100 W

Digital data communication uses low signal levels at high frequencies, making it highly sensitive to surge voltages. Modern SPDs offer reliable protection and meet safety standards under overload or aging conditions. IEC 61643-21 (Edition 2) introduces safety tests for SPDs in signal-processing networks, especially those exceeding 100 W (UC × IL). These include: Temperature resistance test, thermal overload protection test, specific failure test, and overload behavior test under load-side faults.

Disconnection of overloaded protective elements at excessive temperatures

Modern SPDs for signal-processing networks use thermally activated disconnect devices or short-circuit mechanisms, verified through safety tests in IEC 61643-21 Ed.2. In normal operation, the TVSD (Transient Voltage Suppressor Diode) is connected to the signal circuit via low-temperature solder and held by a spring, forming a temperature-sensitive switch.

Under overload, leakage currents heat the TVSD; once a defined temperature is reached, the solder melts and the spring moves the TVSD to a second position, disconnecting it from the circuit. This movement also shifts a plastic element that indicates disconnection and activates remote signaling.

Successful performance of disconnect device

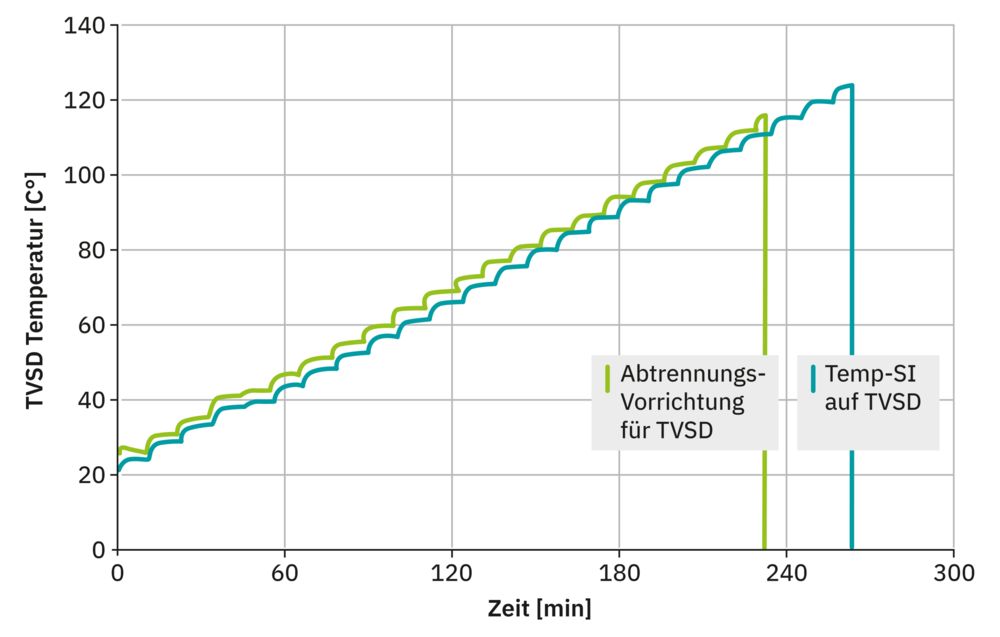

The safety performance of disconnect devices for SMT-mounted TVSDs is demonstrated through a practical application below:

Temperature resistance test: Confirms the device withstands ambient temperatures up to 85°C without shutdown or damage, and no live parts become accessible.

Thermal overload protection test: Monitors surface temperature and current; the device disconnects the TVSD before reaching critical temperature. Compared to a standard thermal fuse, Phoenix Contact’s device shows clear advantages.

Specific failure test: Assesses performance under overload factors (n = 2, 5, 10). In all cases, the SPD entered a safe error mode without triggering the backup fuse, highlighting fast response and strong switching capability.

Reliable protection of the product and environment

The test uses overload factors (n = 2, 5, 10) to assess SPD performance under conditions like output terminal short circuits. In each case, the external fuse interrupted the current, and the SPD’s housing temperature stayed within an 80 K increase, confirming safe overload handling.

Additionally, IEC 61643-21 Ed.2 introduces new safety requirements to prevent energy transmission risks over data cables. To meet these standards, modern SPDs include shutdown or short-circuit devices. This article highlights how TERMITRAB’s disconnect device ensures reliable protection during overloads.

Protection at higher system voltages and/or a high short-circuit potential

Sensor data transmission and power are increasingly combined in a single cable, prompting updates to SPD standards for signal processing networks. IEC 61643-21 Edition 2 formalizes these extended safety requirements. This article outlines the new provisions and shows how built-in disconnect devices enable SPDs to reach a safe failure state under aging or overload, even in high-voltage or high short-circuit conditions.

Complete system with a narrow design

TERMITRAB complete is the world’s narrowest surge protection solution for MCR technology, offering a full system from basic single-stage to advanced pluggable versions with knife disconnection, signaling, and remote signaling. At just 3.5 mm wide, it saves up to 50% space compared to 7 mm devices. Mechanical indicators show device status without auxiliary power, while optional remote modules monitor up to 40 devices and send group alerts to the control room during thermal overloads.

Learn more about surge protection for MCR technology.