DC technology: Test facility shows potential savings

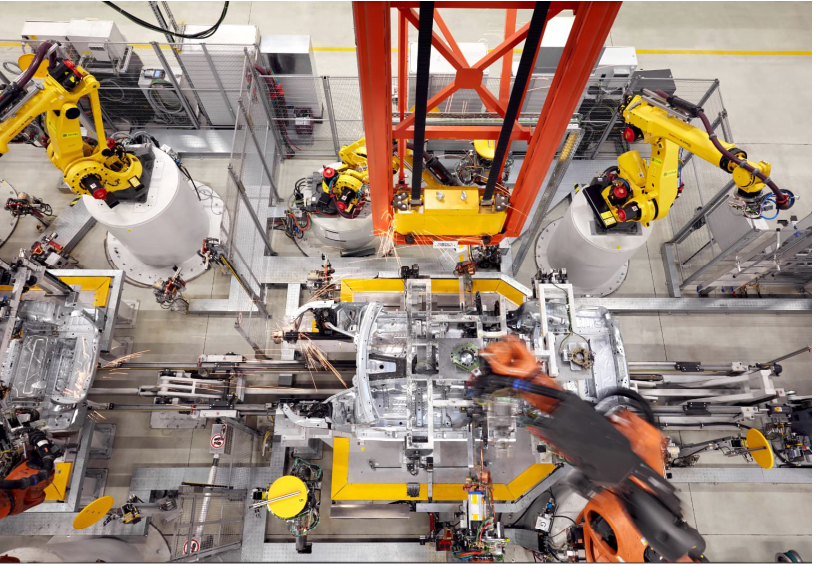

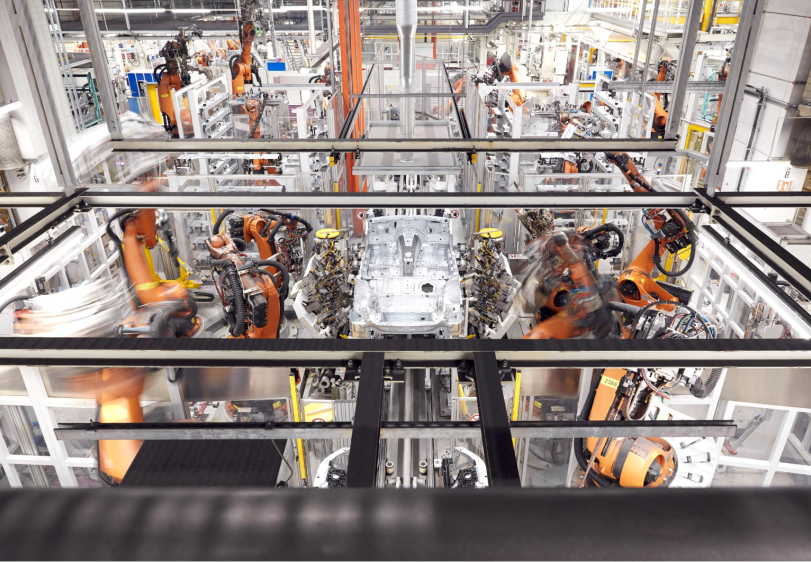

DC grids in the automotive industry are a key step towards climate neutrality. A production plant in Dingolfing, Bavaria, uses Phoenix Contact components to supply a unique DC grid system for robotic arms and automotive parts.

It was AC power supply in the beginning

In the late 19th century, Thomas Edison (DC) and George Westinghouse (AC) fought over large-scale power grid supply. Ultimately, choosing alternating voltage is due to AC voltage’s ability to be transformed up and down.

The advantages of direct current

DC technology offers efficient direct current usable at a low cost. Making it suitable for electronic devices, electric cars, and renewable energy. Furthermore, DC grids can eliminate lossy AC/DC conversion and integrate renewable energy systems efficiently. Moreover, Phoenix Contact provides solutions for intelligent control of power flow and networking, ensuring high availability and supply security.

Direct current as a key technology

Phoenix Contact, a family-owned company, has been supporting BMW in their research into using Direct Current (DC) technology in a production cell at their Dingolfing plant. The company, a member of the Open Direct Current Alliance, has been able to provide rapid support and optimize the existing DC product portfolio through practical applications. This move aims to use renewable energy efficiently and conserve energy and material resources in an All Electric Society.

From theory to practice

Phoenix Contact’s High Power Systems range converts public AC grids into DC grids with 19-inch devices connecting DC subnetworks. Moreover, the wide output voltage range allows gradual ramping up the grid. Furthermore, the performance parameters can be parameterized via the PLCnext platform. Phoenix Contact’s Contactron ELR HDC DC circuit breaker and ArcZero connector ensure safe plugging and unplugging under load.

Read more about DC grids in industry and Solutions for automotive manufacturing.