Identifying and exploiting significant savings potentials

Boehringer Ingelheim, like many companies, aims for sustainable operations by reducing resource use. For instance, an energy requirements analysis based on automation technology from Phoenix Contact helps reduce the consumption of a test system for cartridges by 10%.

Boehringer Ingelheim, a family-owned company since 1885, is a global leader in pharmaceutical research, operating in over 130 markets. With around 53,000 employees across Human Pharma, Animal Health, and Biopharmaceuticals, it develops innovative therapies to address unmet medical needs and improve lives today and for future generations.

Life forward” is Boehringer Ingelheim’s guiding motto, reflecting its optimistic outlook and commitment to shaping a better future. This forward-thinking approach also drives the company’s focus on sustainability.

No changes to the system or interruption of ongoing production

As a pharmaceutical company, Boehringer Ingelheim must meet strict production standards; therefore, even minor process changes require certification. In cartridge production for inhalers, special vacuum pumps check each unit’s tightness. Currently, with 10 pumps consuming 55 kW, the company sought a precise energy analysis without disrupting operations or altering the system. Since the system runs even during production pauses, identifying optimal times to shut down the pumps is key to improving efficiency.

A non-contact method for measuring consumption was implemented to avoid altering certified production processes. At the same time, potential energy savings were identified to reduce electricity costs and support Boehringer Ingelheim’s sustainability goals across all divisions. As an innovation-driven company, it also seeks to test and adopt cutting-edge technologies to actively shape progress in all areas of its operations.

Recording actual energy variables almost in real time

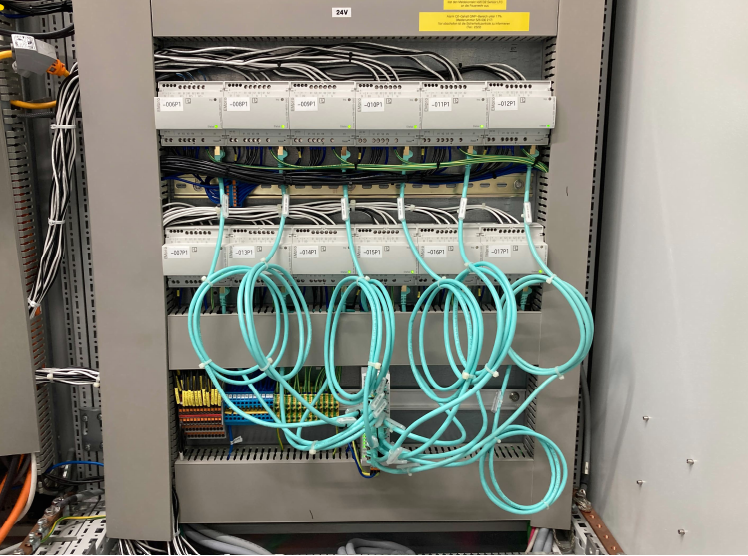

To preserve the certified system, measuring devices were installed in a separate area of the control cabinet, isolated from the system controller during operation. Measuring clamps placed around each phase cable of a vacuum pump enable near real-time energy data collection without altering the electrical setup. The high sampling rate allows for detailed temporal energy curves beyond basic consumption. Ten Phoenix Contact EMpro meters capture the data, connected via Ethernet to measuring terminal blocks. Data is evaluated using the compact EPC 1522 edge device from the PLCnext Technology ecosystem, with communication via Modbus. The setup is powered independently through a 230 V socket in the test-system control cabinet.

Boehringer Ingelheim, having had positive experiences with Phoenix Contact in past projects, is also pleased with the current test system. They highlight Phoenix Contact’s deep industry expertise, reliable partnership, and swift implementation of requirements. All components were precisely adapted to the stringent conditions of pharmaceutical production, with expert support readily available. PLCnext Technology’s openness to third-party products—supporting current and future protocols and integrating external software—adds further value. Boehringer Ingelheim is now exploring protocols like NodeRed and MQTT, along with new databases and visualization tools.

Determining further factors influencing energy consumption

The joint energy analysis revealed valuable insights: for instance, shutting down the system after 15 minutes of standby can cut energy use by 10%, a vacuum line leak was identified as a major power drain, and the pumps were found to be oversized for the task. Altogether, these findings support Boehringer Ingelheim’s goals to reduce energy use by 10% and halve its carbon footprint by 2030—with Phoenix Contact as a strong partner.

Advantages of the energy requirements analysis at a glance

- Implementation of a state-of-the-art solution during ongoing production

- self-contained measurement system integrated seamlessly

- Open PLCnext Technology ensures compatibility with all components

- Phoenix Contact’s expert team supported every project phase collaboratively

The open PLCnext Technology ecosystem for current and future automation requirements

PLCnext Technology is an industrial automation ecosystem combining open hardware, modular software, a global community, and a digital marketplace. This setup allows easy adaptation to changing needs and efficient use of current and future technologies, software, and collective intelligence.

The open automation system’s tailored design and modular expandability are key advantages. PLCnext Control supports real-time programming in IEC 61131-3, C/C++, C#, and Matlab/Simulink. The free PLCnext Engineer tool accelerates development, while cloud integration, open-source support, and the growing PLCnext Community foster collaboration. Apps, software blocks, and extensions available in the PLCnext Store help reduce development time and costs.

Read more about Leakage monitoring, Data-driven sustainability, and digital factory.