Evaluating the requirements on connection technology holistically

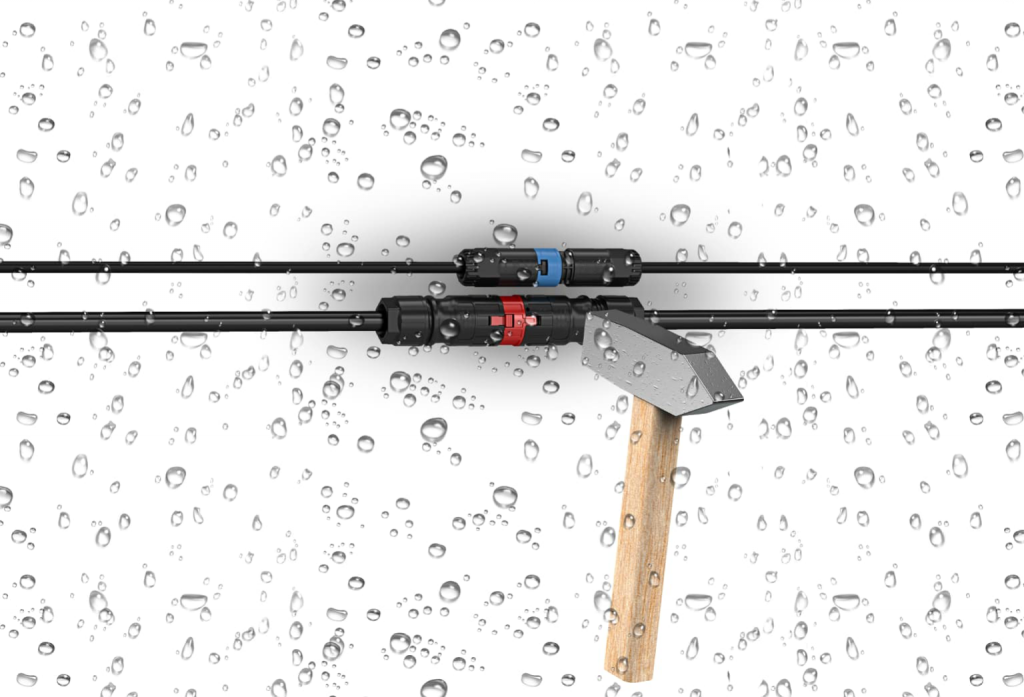

Industrial systems require high-performance installation connectors to be robust, reliable, and flexible. These connectors must not become weak points, especially in extreme ambient conditions like cold water systems. These systems, often modular, must withstand moisture, frost, heat, and UV light for years without problems. Outdoor components, like cooling coils, require high IP protection and weather resistance. Connectors should enable intuitive operation during installation, commissioning, and maintenance, and ensure fast, error-free connections for power supply, signal transmission, and data transfer. These connectors are suitable for various industrial installations.

The challenges in practice

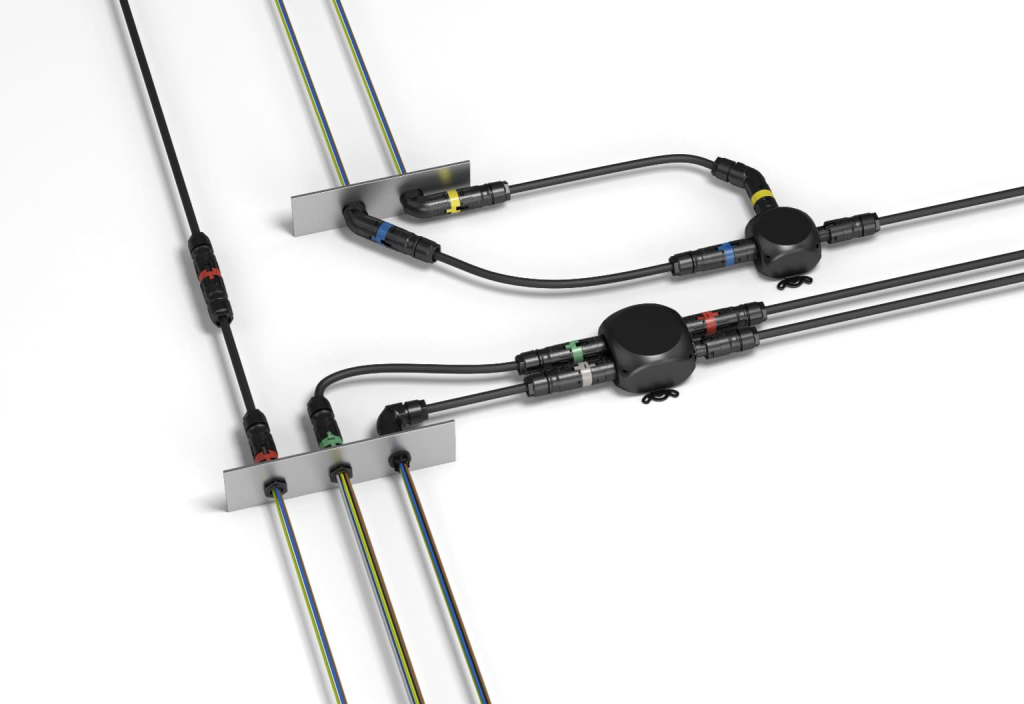

Device and system developers face challenges in creating reliable connection systems for IIoT and Industry 4.0 applications. Phoenix Contact’s PRC series offers high-performance power, signal, and data connectivity, IP6X protection, and UV resistance. The series includes circular connectors and assembled cables, with special housing inserts for a defined terminal point on the field device.

Standardized basis for safe connectors

Standardized connectors are advantageous in everyday life, smartphone market developments, and electric vehicle introductions. Standards like IEC 61984 and IEC 61535 define safety requirements and tests for connectors, while application-specific standards ensure permanent connections in fixed installations. These standards form a solid basis for power distribution, ensuring user safety and reliable connections.

Failure causes and starting points

The reliability of a system depends on its weakest link, and follow-up costs often outweigh the cost of materials or spare parts. Minimizing system failure risk is crucial, considering maintenance costs and intervals. Low-investment components often lead to failures, while quality upgrades can reduce costs. Cutting costs on connection technology can make error diagnostics difficult due to sporadic problems.

Selection criteria

Planners should consider key characteristics like current, voltage, and conductor cross-sections, as well as seal tightness. The IP degree of protection, as per IEC 60529, defines protection against contact, foreign bodies, and water ingress. Higher IP degrees result in better seal tightness, with groups like IPX6, IPX5, IPX8, IPX7, and IPX9 forming groups.

General conditions are decisive

Repairs, maintenance, or inspections on existing systems can cause damage if connectors are loosened or the terminal box is opened. This can be due to inadequate design or incorrect selection of connectors and mounting materials. Environmental conditions, such as humidity, temperatures, UV irradiation, and wind, can affect the materials used, causing brittleness or corrosion. Substances in the environment, such as ammonia, sulfur, and salts, can also affect the materials. Environmental simulations and tests, such as ISO 4892, DIN EN 60068-2-52, 2 PfG 1911, and ISO 6988, are essential for material resistance. Impact and vibration tests are also necessary for mechanical load resistance. The Phoenix Contact product portfolio offers PRC series connectors for energy technology applications, such as lighting, infrastructure, and power distribution. These connectors are designed for fixed and permanent installations and feature high stability even with frequent plugging and unplugging. The PRC 20 series supplements existing products for up to 35 A and can be used indoors and outdoors.

Learn more about Phoenix Contact’s PRC series.