Customized solutions for classic point-to-point applications

Phoenix Contact offers a range of signal conditioners and measuring transducers for point-to-point wiring in industrial environments. These devices are used to safely isolate, filter, amplify, and convert electrical signals from field devices. The Mini Analog Pro series features intrinsic safety and functional safety, while the revised MACX Analog Ex device family and VIP I/O marshalling provide a comprehensive range of signal conditioners and measuring transducers. In addition, point-to-point wiring offers advantages such as easy installation, high flexibility, easy troubleshooting, and less interference. However, the wiring can be disadvantageous as each device must be connected to the controller. The Termination Carrier from Phoenix Contact eliminates this issue.

The main spectrum of tasks

Moreover, signal conditioners and measuring transducers are essential for safely isolating, filtering, amplifying, and converting electrical signals.

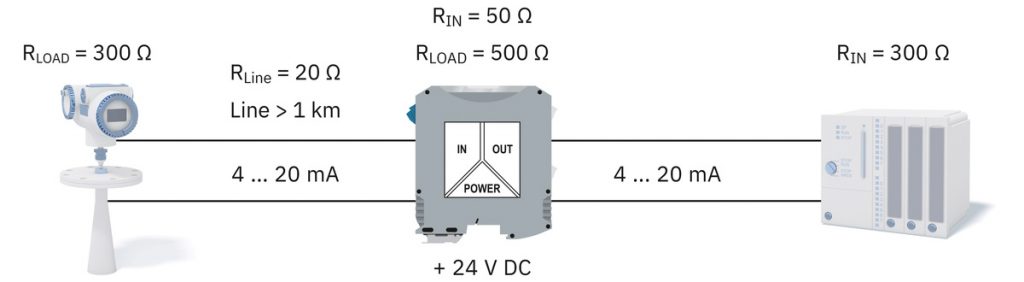

Signal amplification

Moreover, signal amplification is necessary when a weak signal and can therefore only be acquired in distorted or attenuated form. For example, adding an amplifier reduces the load connected to the measuring sensor to 70 ohms, preventing distortion and ensuring the measurement signal remains accurate.

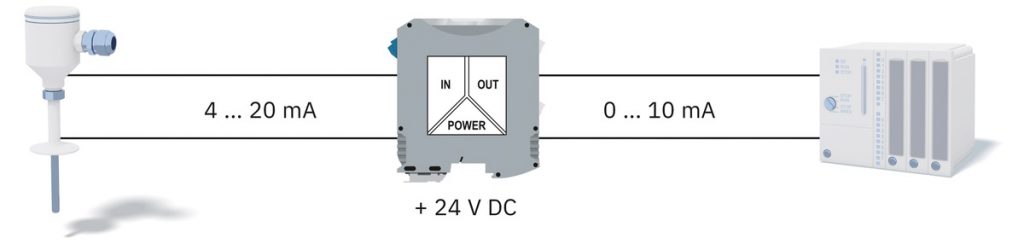

Conversion to a standard signal

Depending on the measuring task, analog sensor signals can be converted into standard signals in an interface block. The conversion result should be proportional to recorded input values, to avoid distortion. Moreover, the standard signal converter adjusts the required signal between the transmitter and the evaluation unit.

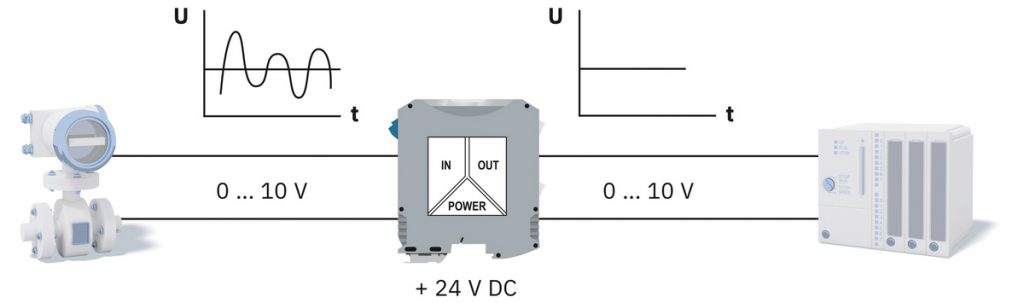

Filtering

Furthermore, interference voltages in cables for measured value transmission can occur due to electromagnetic induction or high-frequency signals. Signal conditioners with filter functions detect and suppress these voltages, while twisted or shielded cables reduce induced voltage. To avoid interference, convert voltage signals into current signals.

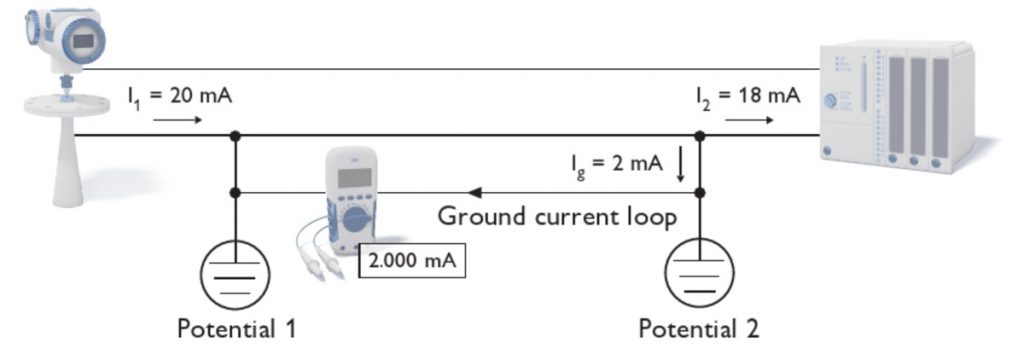

Electrical isolation

An electrically isolated signal connection, referred to as a floating connection, is essential in the plant and process industry. It eliminates compensating currents between potential differences, ensuring the recording of identical signals. This is achieved by integrating a galvanic signal isolator into the connecting cables.

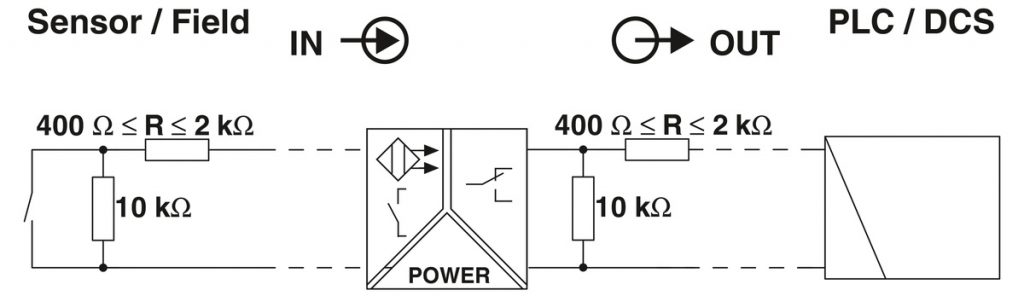

Line monitoring

Line monitoring is a crucial function in interface blocks, ensuring line interruptions and short circuits. It is detailed in NE 21 NAMUR recommendations. The figure illustrates line monitoring on the entire signal transmission path, with resistances ranging from 400 to 10 kΩ, ensuring maximum current and zero current in line breaks.

The diverse areas of application

Furthermore, the tasks described are required in various industries, including chemicals, oil and gas, infrastructure, cement, machine building, and renewable energies like wind and solar power.

Industrial process control

Signal conditioners and measuring transducers are commonly used in industrial applications to isolate, convert, and amplify analog signals from sensors or measuring devices for precise and reliable monitoring and control of the process.

Energy monitoring

Furthermore, devices are utilized for energy monitoring, accurately measuring and controlling energy consumption in buildings and industrial plants by isolating and amplifying electrical signals from current and voltage sensors.

Monitoring of process variables

Lastly, Phoenix Contact provides signal conditioners and measuring transducers for monitoring sensor signals, conforming to explosion protection standards, international approvals, functional safety certifications, and maritime applications.

Discover more about Signal conditioners and measuring transducers.