Clever alternative for remote consumption locations

Endua has partnered with Phoenix Contact to enhance its modular hydrogen energy storage system. Using PLCnext Control with integrated safety, the Australian start-up boosts efficiency, cuts costs, and ensures a safe working environment.

Brisbane based start-up Endua develops hydrogen powered energy storage systems designed for remote off grid users such as mines and communities.

With support from CSIRO, Ampol and Main Sequence, its clean and reliable solution enables multi day storage from renewable sources, even during periods of low sunlight and wind, offering a more sustainable alternative to diesel generators.

Endua’s modular power bank uses hydrogen electrolysis powered by renewable energy to split water into hydrogen and oxygen. Stored hydrogen powers fuel cells on demand, enabling multi day energy storage that outperforms typical lithium ion batteries, which are limited to shorter durations. Endua was founded in 2021 to commercialize CSIRO’s PEM electrolysis research, according to Tim Latimer, Head of Growth and Business Development.

Self-sufficient hydrogen system for storing energy over several days

According to the World Economic Forum, 85 percent of hydrogen costs come from storage, compression and transportation, raising concerns about its economic viability. To reduce costs, large hydrogen production should be near the industries that consume it. Latimer explains that infrastructure costs are a major challenge, especially for smaller users facing high transport expenses. A self-sufficient system that allows on-site hydrogen production, storage and use is a practical solution. In specific cases, hydrogen is already competing with lithium-ion batteries and fossil fuels. For energy storage lasting days to weeks, the cost per kilowatt hour in a power bank is more favourable than lithium batteries.

The Endua power bank system offers key advantages:

- Modular and scalable design: The flexible storage solution lets users scale energy capacity to meet needs, from small remote communities to large industrial sites.

- Reliable off-grid performance: Ideal for industries using diesel generators, enabling a switch to hydrogen with reduced emissions and consistent reliability.

- Renewable energy integration: The system stores surplus renewable energy during peak times, ensuring power supply even when production is low.

- Long-term storage: Endua’s hydrogen technology stores energy for several days, making it ideal for applications that require extended power availability.

Partnership-based implementation of a flexibly adaptable solution

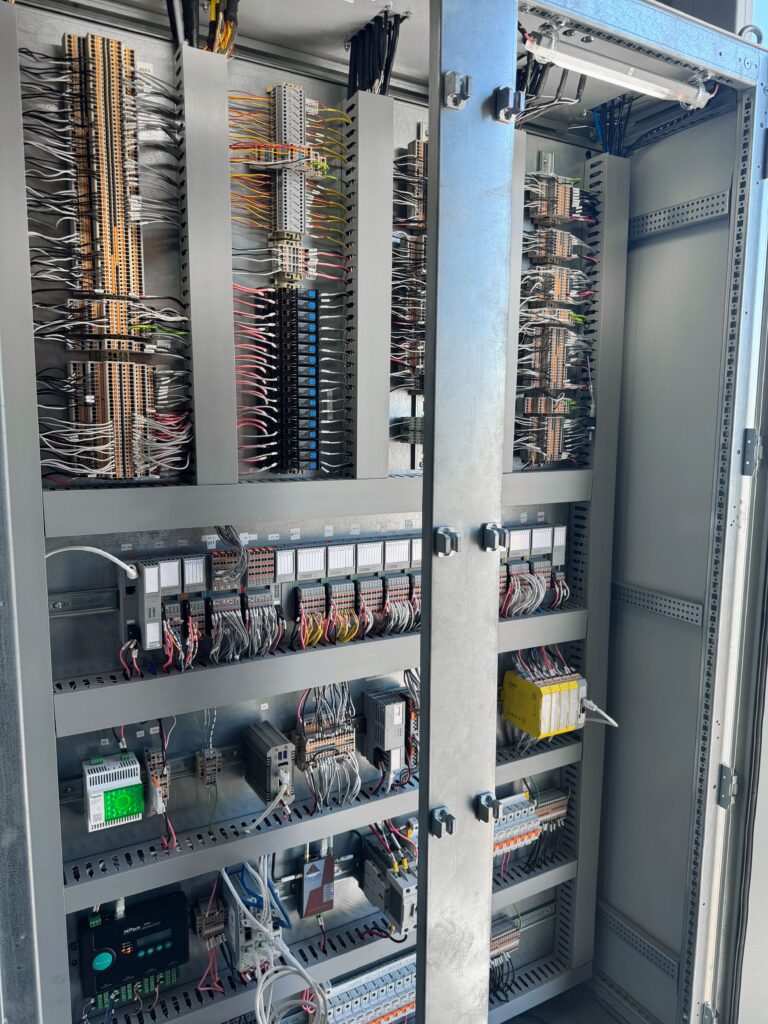

The successful testing of Endua’s first power banks confirmed the concept’s viability. To ensure reliable, scalable and precise control and safety, Endua partnered with Phoenix Contact to create a flexible solution with global support. Phoenix Contact’s international reach enables worldwide manufacturing and service. Adam Davidson, Control Systems Engineer at Endua, notes that sourcing all control system components from one supplier ensures consistent quality and reduces design and procurement costs.

The first power banks included PLCnext Control and PSRmodular safety technology. In order to accelerate development and commissioning, Endua turned to Phoenix Contact’s application engineers.

During setup, however, Davidson explains that issues emerged with reading analog signals from gas detectors because of wiring errors and misconfigured modules. Fortunately, Phoenix Contact’s team promptly identified and resolved the problems.

Cloud Monitoring for Hydrogen Powerbank Components

Phoenix Contact’s PLCnext Control supports both IEC 61131-3 and high-level programming languages. Its modular design, using Axioline and Inline I/O systems, allows easy adaptation to specific needs. The PSR safety modules come with TÜV-certified software, enabling Endua to build safety logic with minimal programming expertise.

Endua power banks require regular maintenance. Users replace water and air filters, while certified technicians calibrate gas detection systems. Engineers design PEM electrolyzer stacks for on-site replacement. As efficiency declines over time, Phoenix Contact’s industrial PC and communication hardware facilitate the maintenance process.

Endua monitors systems remotely through a cloud platform using Ignition software on the PC. The PC converts control data into MQTT and transmits it to the cloud, where the system tracks component performance to anticipate maintenance needs essential for remote applications.

Numerous advantages of the control and safety system

Endua is currently developing a second-generation test system using PLCnext Control controllers, which integrate control, safety, and IPC functions into a single unit. Consequently, this setup improves monitoring, enhances data access, and reduces overall costs. In addition, programming within the PLCnext Engineer environment and loading code directly onto the controller streamlines development while enriching system data.

The integrated PLCnext Control with functional safety offers major benefits over the original power bank setup, says Eduardo Aruda, Product Manager at Phoenix Contact Australia. It simplifies system architecture by combining automation and safety in one solution, reducing design complexity and errors. A unified programming environment allows engineers to develop both functions on a single platform, ensuring consistency and compatibility.

Read more about Solutions for power-to-X