The necessity of surge protection in process engineering systems

Surge protection and equipotential bonding are established in the process industry. In explosive areas, consistent bonding and, if needed, surge protection are essential. The APL products can be integrated into existing grounding and shielding concepts, where high-quality bonding ensures system availability. They allow cable shielding decoupling alongside classic one- or two-sided grounding. For field use requiring maximum failsafe performance possible, the trunk is implemented via fiber optics with an integrated SFP module, though RJ45 remains an option.

Surge protection for APL signals

Phoenix Contact, a leading manufacturer of lightning and surge protection, has developed new products that integrate seamlessly with existing signal overvoltage families and accessories. Their development incorporated relevant standards and cross‑manufacturer user recommendations, implemented alongside the products.

Moreover, the TTC-6P-3-APL-EX-24DC-UT-I surge protection device is tailored for APL requirements, particularly its frequency properties. Its internal wiring with voltage-limiting components supports 10 Mbps, ensuring no impact on data transmission between switches or field devices. APL transmission properties are defined in the IEEE 802.3cg standard under 10Base-T1L.

Additionally, the surge protective device is suitable for the demanding conditions of the process industry, where distributor boxes are often installed outdoors. Phoenix Contact’s APL products are approved for temperatures from -40°C to 85°C and withstand corrosive gases or explosive mixtures. They are robust, corrosion-resistant, Ex-certified, and thus highly flexible in use.

The signal circuits between the APL switch and field devices are intrinsically safe. Surge protection is easily implemented in 2-WISE (Two-Wire Intrinsically Safe Ethernet) systems. The DIN CLC IEC/TS 60079-47 standard defines the parameters for these configurations. Similar to the Fieldbus Intrinsically Safe Concept (FISCO), limits for energy, current, and voltage simplify proof during Ex i system approval. The surge protective device is certified as a 2-WISE Auxiliary Device. Parameters such as UI and II are already approved, allowing straightforward integration into intrinsically safe APL circuits.

Specifications from the user environment

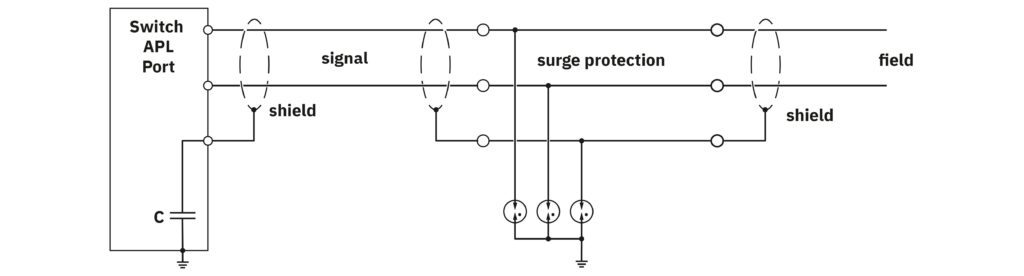

Technical documents on the APL environment have been developed with user committees such as Profibus, ODVA, FieldCom Group, and the OPC Foundation. The Port Profile Specification requires APL devices to include surge protection to strengthen system dielectric capacity and safeguard signal wires and cable shielding against ground potential. For this, surge protection uses high‑performance gas discharge tubes. Devices are installed close to the components to be protected (typically the APL switch), with branch cables connected via through‑wiring. Signal wires are wired to two terminals, while a third terminal connects the cable shielding. Accessories enclose the braided shield and transfer its potential to the terminal block.

Furthermore, cable shielding can be grounded indirectly via coupling capacitors to the switch, or directly to ground through accessories and a common shield bus. In both cases, surge protection is easily integrated into the installation.

Learn more about Ethernet-APL system.