A digital solution for customer-specific marking solutions

Application-specific, standard-compliant identification is key to quality, safety, and availability in industrial plants. Yet evolving requirements, complex standards, and cost pressures pose challenges. Phoenix Contact shows how digital, customer-specific marking solutions support future-proof production.

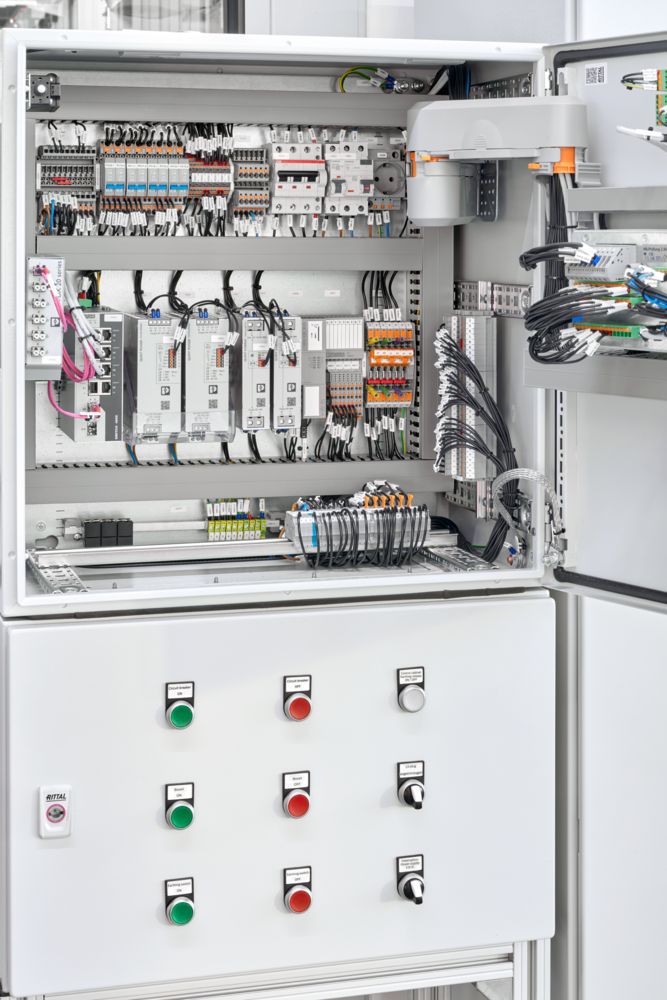

In industrial settings, system functionality takes priority, often overlooking component identification. Yet in control cabinet and systems manufacturing, clear labeling is vital—enhancing quality assurance, streamlining commissioning, speeding up diagnostics, and reducing downtime during maintenance. This small detail plays a key role in industrial plant reliability and availability.

Normative standards require consistent identification to ensure compliant documentation and protect people and machines. Safety rules, such as IEC 61439 for low-voltage switchgear, highlight its importance. Industrial identification is now vital to modern production and a key part of value creation, especially in control cabinet building.

Challenges of industrial identification

Standard-compliant identification of devices, components, and circuits is challenging for control cabinet builders and system manufacturers. Terminals, wires, cables, and equipment must be clearly and permanently marked even under harsh conditions like temperature, humidity, or vibration. Varying applications and environments demand different mounting types and durable markings. Time and cost pressures, changing formats, and manual processes increase error risks, costs, and delays. Small batch production and special materials add further complexity.

Many companies do not have their own marking systems and must manage order peaks and maintenance. Flexible, accessible, and customizable marking solutions are essential for quick, tailored responses.

The right marking solution for every situation

Phoenix Contact provides a comprehensive solution for efficient marking processes, with various printing technologies, versatile marking materials, intuitive marking software, and comprehensive services.

Phoenix Contact’s Marking Configurator offers a user-friendly, fully digital ordering process for custom marking materials starting from a batch size of one. With over 2,000 ready-to-use options, including plastic, aluminum, and stainless steel markers, it delivers flexible, application-specific solutions without requiring in-house printing systems or risking production delays.

Configure custom marking solutions and order them online.

The Marking Configurator streamlines ordering by starting with material selection in Phoenix Contact’s online shop. Users click “Configure version” to begin customizing via an intuitive interface no prior experience needed. Even complex designs with logos, symbols, and barcodes are easy to create, with real-time previews to prevent errors. After configuration, users set quantities and receive instant pricing. Saved projects can be reordered with a few clicks, making repeat orders simple. This digital process boosts speed, reliability, and cost-efficiency for custom marking materials.

Marking Configurator – the smart solution for technical precision and cost-effective efficiency

Industrial identification is vital for quality, safety, and efficiency in modern production. With rising complexity and cost pressure, digital, flexible, and user-friendly solutions are essential. Phoenix Contact’s Marking Configurator meets these needs with an intuitive, scalable process from selection to ordering. It helps companies streamline workflows, reduce errors, cut storage costs, and avoid waste, enabling efficient, future-proof production.

Learn more about marking materials.