Challenges and optimization potential for the installer interface

Heat pumps are vital for the energy transition and reducing carbon emissions. A well-designed installer interface between the pump and building services is crucial standardized connections reduce errors and boost system efficiency and reliability.

Structure and function of the installer interface

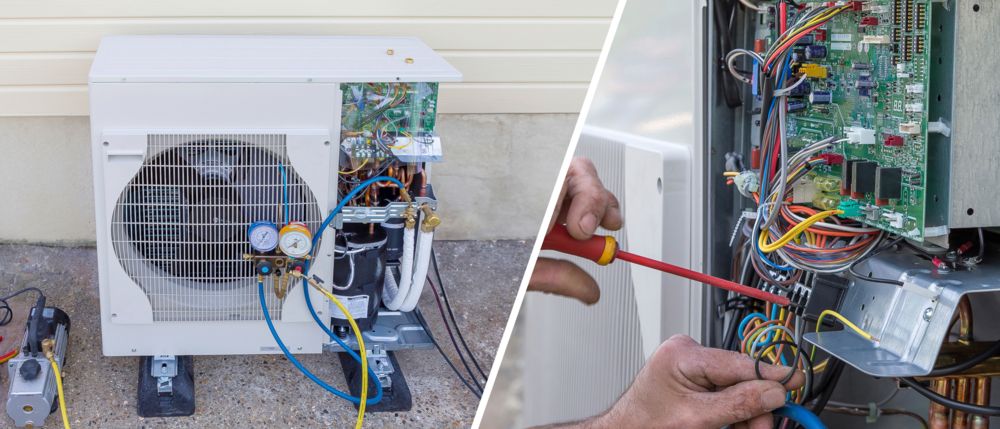

The installer interface connects the heat pump to building services, including power, data cables for unit communication, and terminals for sensors or heaters. Poor design can cause connection errors, impacting performance and efficiency. Modern systems like Push-Lock circular connectors and preassembled cables simplify mounting and ensure fast, error-free installation, especially in tight spaces.

Sources of error during installation

Inadequate identification can cause miswiring and system failures, especially between indoor and outdoor units. Incorrect connections may disrupt heat pump regulation or reduce efficiency in hydraulic components like pumps and manifolds. Single Pair Ethernet (SPE) enables efficient networking of all components, reducing wiring effort and ensuring reliable data communication.

Standardization and optimization of the connection technology

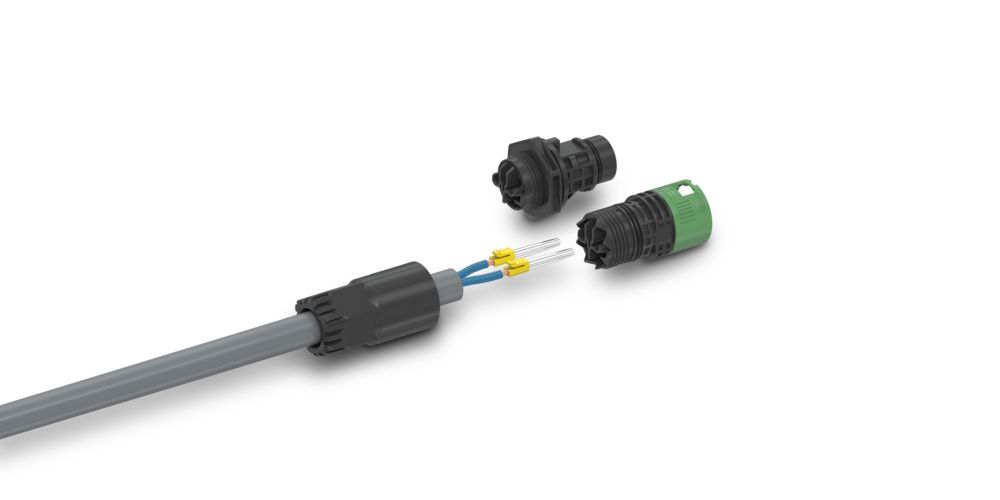

Preassembled connectors and clear markings help prevent installation errors. Plug-and-play solutions simplify setup and speed up commissioning. Push-Lock circular connectors allow safe, tool-free mounting of conductors, with easy handling of fine-stranded wires via a colored lever, minimizing manual errors. Single Pair Ethernet enables centralized communication, reducing maintenance and troubleshooting.

Cost pressure and economic challenges

Heat pump manufacturers face cost pressure due to complex refrigeration and control technology, while demand grows for affordable, easy-to-install solutions. PRC crimp connectors suit mass production, and IPD Push-Lock connectors simplify safe field assembly.

Phoenix Contact’s Push-Lock connection cuts on-site wiring time by up to 80%. Stripped conductors insert easily and lock securely no screwing, fewer errors.

PRC and IPD housings offer up to IP69K protection, making them ideal for harsh environments.

Future prospects and solutions

Optimizing the installer interface speeds up heat pump installation and commissioning. Digital tools like apps or AR guide correct connections. Standardizing interfaces and using Single Pair Ethernet enables cross-manufacturer compatibility, boosting efficiency and user acceptance.

Future use of AI and intelligent networking

AI in control systems boosts heat pump efficiency by adapting to weather, user behavior, and energy costs. Combined with solar and battery storage, it maximizes renewable energy use and cuts grid reliance.

IP-based protocols are key to connecting heat pumps with appliances and power grids. Single Pair Ethernet (SPE) streamlines cabling, simplifies communication, and lowers costs. Designed for low-energy components and hybrid connections, SPE originally from the automotive sector, also cuts development effort.

Learn more about connection technology for heat pumps