Push-X technology for fast direct connection

Efficiency is crucial in manufacturing, driving continuous innovation in PCB connection technology. Tool-free Push-in and lever Push-in systems are already easy to use. Building on this, the new Push-X technology introduces a mousetrap-style mechanism for even faster, tool-free connections.

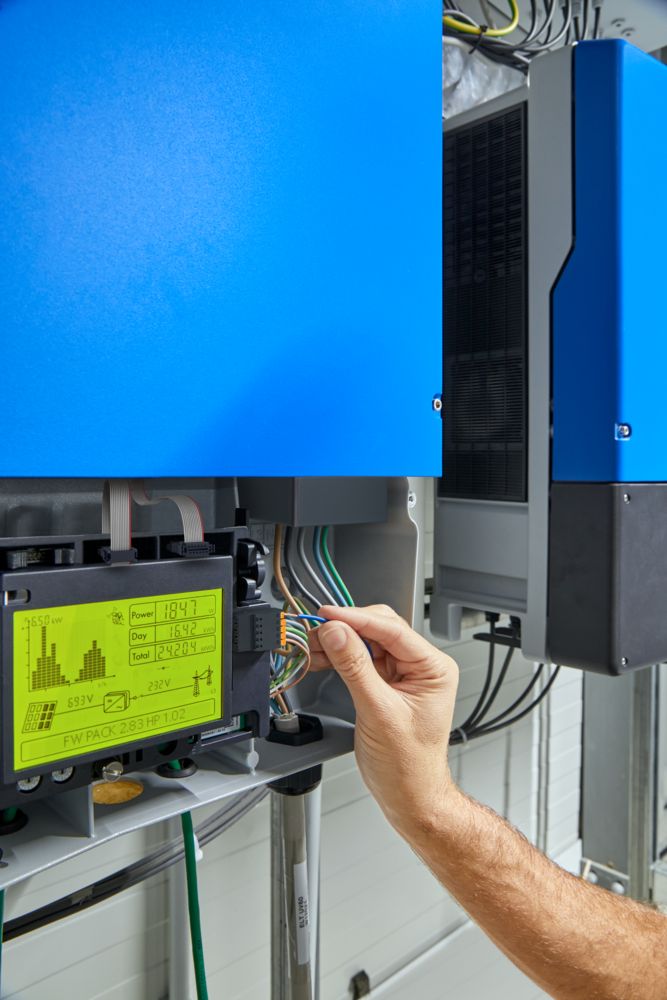

Electrification is essential across all areas of life, making safe and simple PCB connections crucial. User-friendly conductor connection technologies like the Push-in spring connection allow tool-free wiring with rigid and ferruled conductors. However, flexible conductors require opening the clamping spring — a challenge with just two hands. This inspired Phoenix Contact to develop Push-X technology.

Connect flexible conductors easily without tools

The XPC 1,5 connectors are the first PCB components to feature Push-X technology. They allow direct insertion of class 5 flexible conductors (0.5–1.5 mm²) without ferrules — ideal for fieldwork when crimping tools aren’t available. Rigid conductors and ferruled wires are still compatible. Technicians are often surprised by how little force is needed for insertion.

What is the difference between Push-X and Push-in?

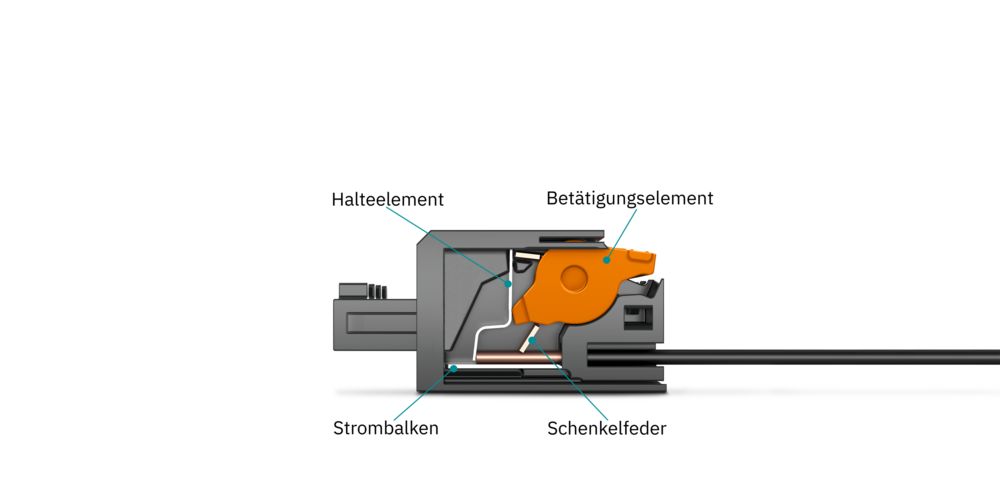

Both Push-in and Push-X connections share a similar structure with female contacts, leg springs, and actuating elements. The key difference: Push-in arrives with the spring closed, requiring the conductor to push it open — resulting in higher insertion force. Push-X, however, comes with the clamping space already open and secured by a retaining element, allowing effortless insertion.

Force-free and tool-free direct-connection technology

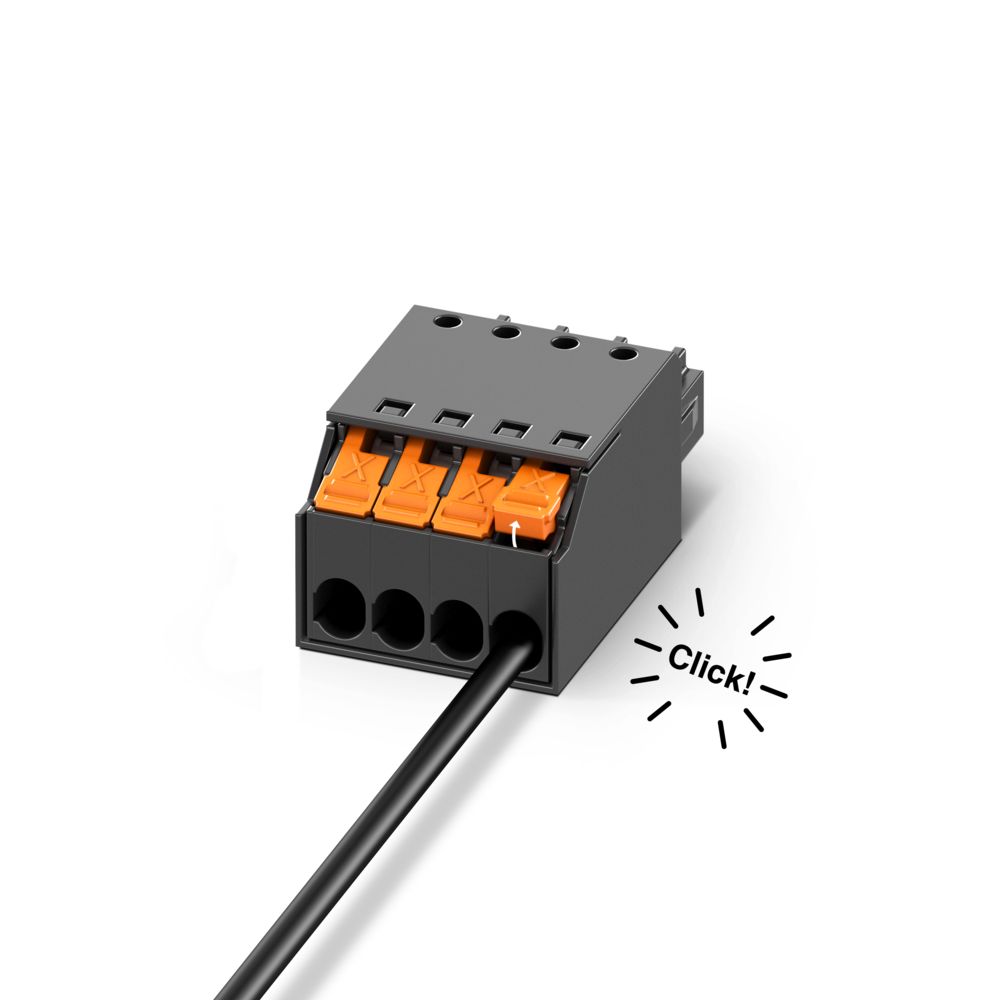

Push-X uses a mousetrap-style mechanism: the leg spring is pre-opened, and inserting the conductor triggers a sensitive release element. This releases the spring, which snaps shut with an audible click, securing the conductor to the current bar for a stable connection. Simultaneously, the orange actuator flips up, indicating the clamping space is closed.

Engineers had to carefully balance sensitivity and stability in the Push-X design to prevent accidental tripping from vibrations. While the mechanism needs to respond easily to small conductors with low force, it must also withstand transport and environmental stress. The XPC 1,5 connectors passed rigorous climate, vibration, and drop tests to ensure open clamping spaces on delivery and compliance with IEC 61984. VDE and UL 1059 approvals confirm their high quality.

Frequent connection of the conductor confirmed

DIN EN 60999-1 requires five connection cycles for the largest conductor size, while UL 1059 requires ten. Lab tests showed no wear even after 25 cycles. To reopen the clamping space, users simply press the orange actuator until it locks in the lower position, automatically resetting the leg spring for the next connection.

Highly compatible

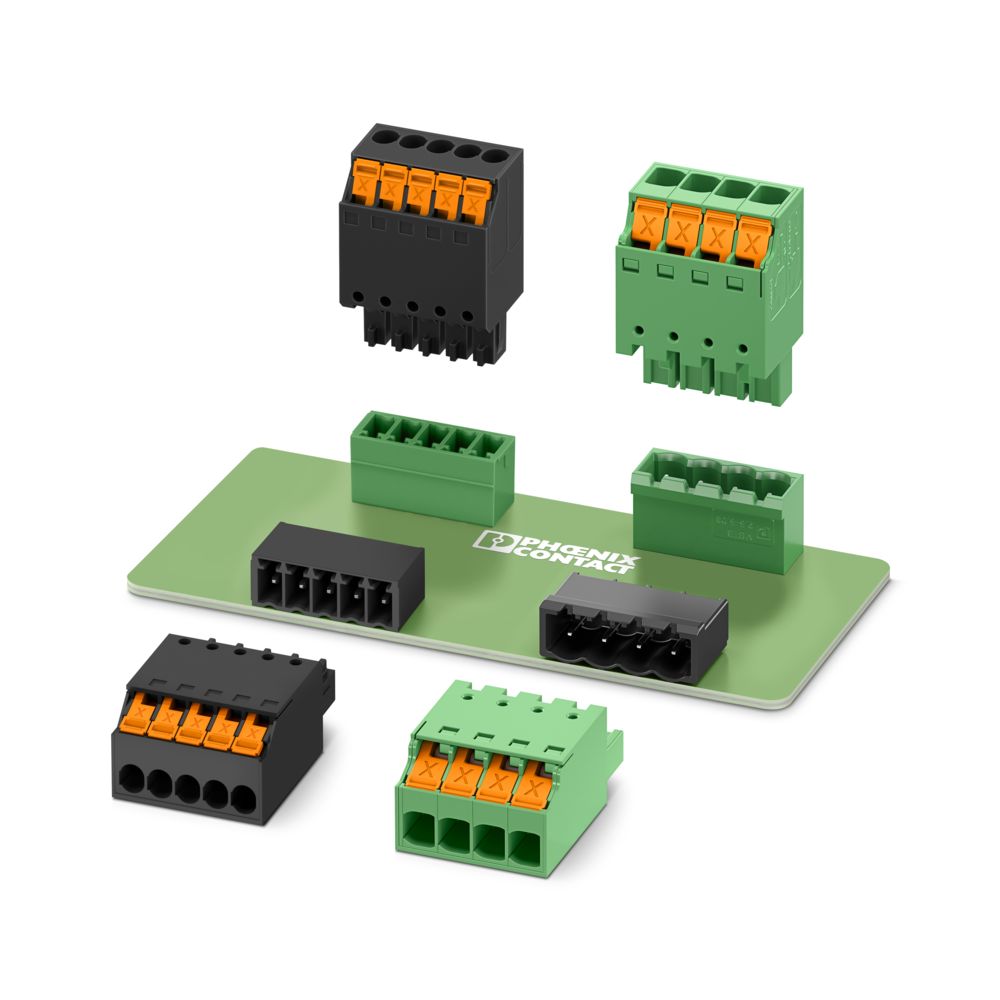

The XPC 1,5 series is fully compatible with Phoenix Contact’s existing 3.5 mm pitch range and can be combined with current horizontal and vertical headers. Additional Push-X products for larger conductor sizes will launch later this year with the XPC 2,5 series.

Electrical function test in the application

Alongside Push-X technology, XPC 1,5 connectors offer practical features like top-mounted test openings for in-application electrical testing. Each position’s current bar can be accessed directly with 1 mm test probes.

Learn more about Push-X in the XPC 2,5 PCB connector.